BRAKES - REAR MECHANICAL

Page K-13

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

9. Measure the brake shoe thickness.

Measure at the most worn area. Brake shoe thick-

ness must never be less than .06" (1.5 mm) at any

point on the shoe. It is normal for the shoes to show

more wear at the leading and trailing edges (Ref Fig.

16 on page K-13). If the brake shoe thickness is

approaching .06" (1.5 mm), it is recommended that

the shoes be replaced. It is recommended that the

brake shoe springs and brake adjusters be replaced

when installing new brake shoes.

10.Inspect the brake shoe springs.

Be sure that they are not broken or damaged and are

correctly installed. The hooked end of the adjuster

spring is inserted through the front of the front shoe

and the opposite end hooked to the adjuster with the

hook end facing out. The brake shoe springs must be

installed with the light spring closest to the adjuster

mechanism with the hook installed down through the

rear brake shoe and up through the front brake shoe.

The heavy top spring is installed with both spring

hooks installed down through the brake shoes (Ref

Fig. 17 on page K-13).

11. Repeat procedure at the opposite wheel brake.

12.Check/adjust brake pedal free travel.

Whenever the brake system is serviced or requires a

parts replacement, the brake pedal free travel must

be checked and adjusted. See ‘Adjusting Brake Pedal

Free Travel’ on page K-14. This includes all linkage and

wheel brake components.

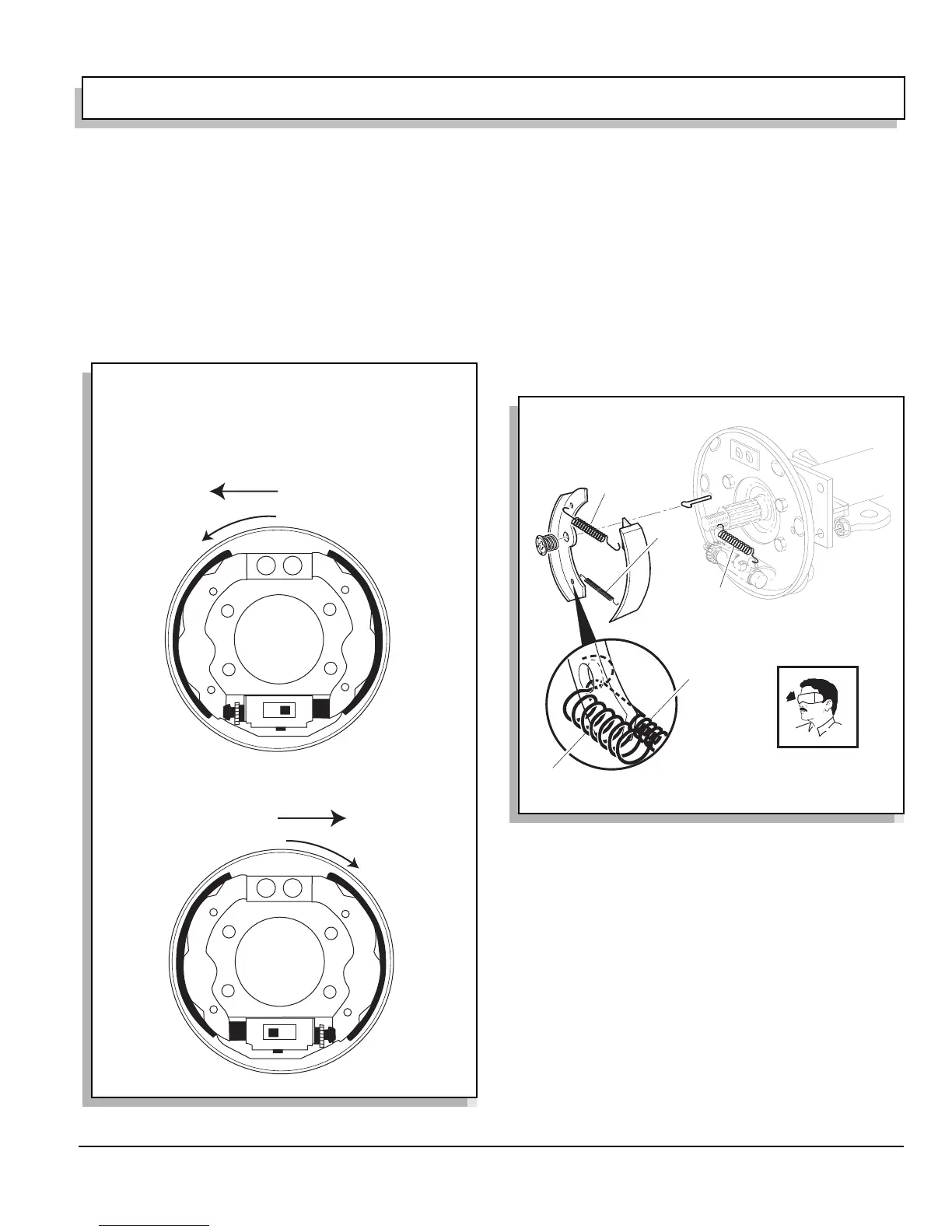

Fig. 16 Brake Shoe Wear

Forward

Forward

A

A

B

B

C

C

D

D

Drum Rotation

Drum Rotation

Driver side

Passenger Side

The pattern of normal brake shoe wear is

shown in quadrant ‘A’, ‘B’, ‘C’ & ‘D’ with

quadrant ‘A’ showing the most wear.

Quadrant ‘B’ will show the second most wear.

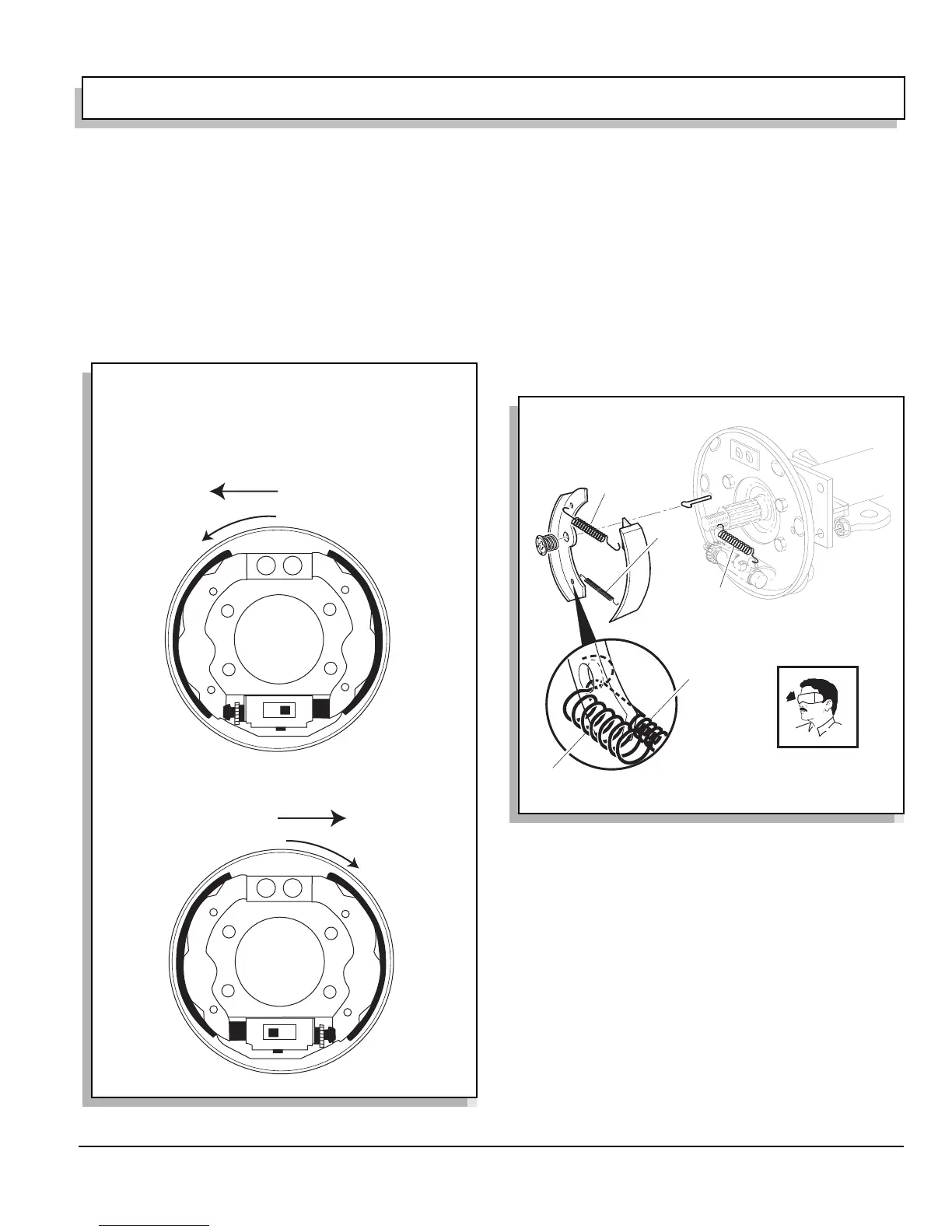

Fig. 17 Orientation of Brake Shoe Springs

Heavy Shoe

Spring

Light

Shoe

Spring

Adjuster

Spring

Adjuster

Sprin

Light

Shoe

Spring

Loading...

Loading...