FRONT SUSPENSION AND STEERING

Page E-14

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

Check front wheel alignment and adjust if necessary.

See ‘Wheel Alignment’ on page E-3.

Rack and Pinion Unit Disassembly and

Inspection

Tool List Qty. Required

Vice .............................................................................1

Socket, 3/8", 3/8" drive................................................1

Ratchet, 3/8" drive....................................................... 1

Wrench, 11/16"............................................................ 1

Wrench, 3/4"................................................................ 1

Wire cutter................................................................... 1

Retaining ring pliers..................................................... 1

Shop towel................................................................ AR

CITGO Lithoplex MP No. 2 grease........................... AR

Wire tie, 8" long ...........................................................1

Wire tie, 10" long ......................................................... 1

Torque wrench, 3/8" drive, in. lbs. ...............................1

The rack and pinion gears are not serviceable

items. If they are found to be damaged or

excessively worn, a new rack and pinion unit must be installed.

Secure rack and pinion unit in vice by

the mounting ears only. The rack and

pinion unit is made of aluminum and can be damaged if held oth-

erwise.

Remove rack and pinion unit from vehicle. See ‘Rack

and Pinion Unit Replacement’ on page E-15. Anchor in

vice by clamping on the mounting ears of the unit.

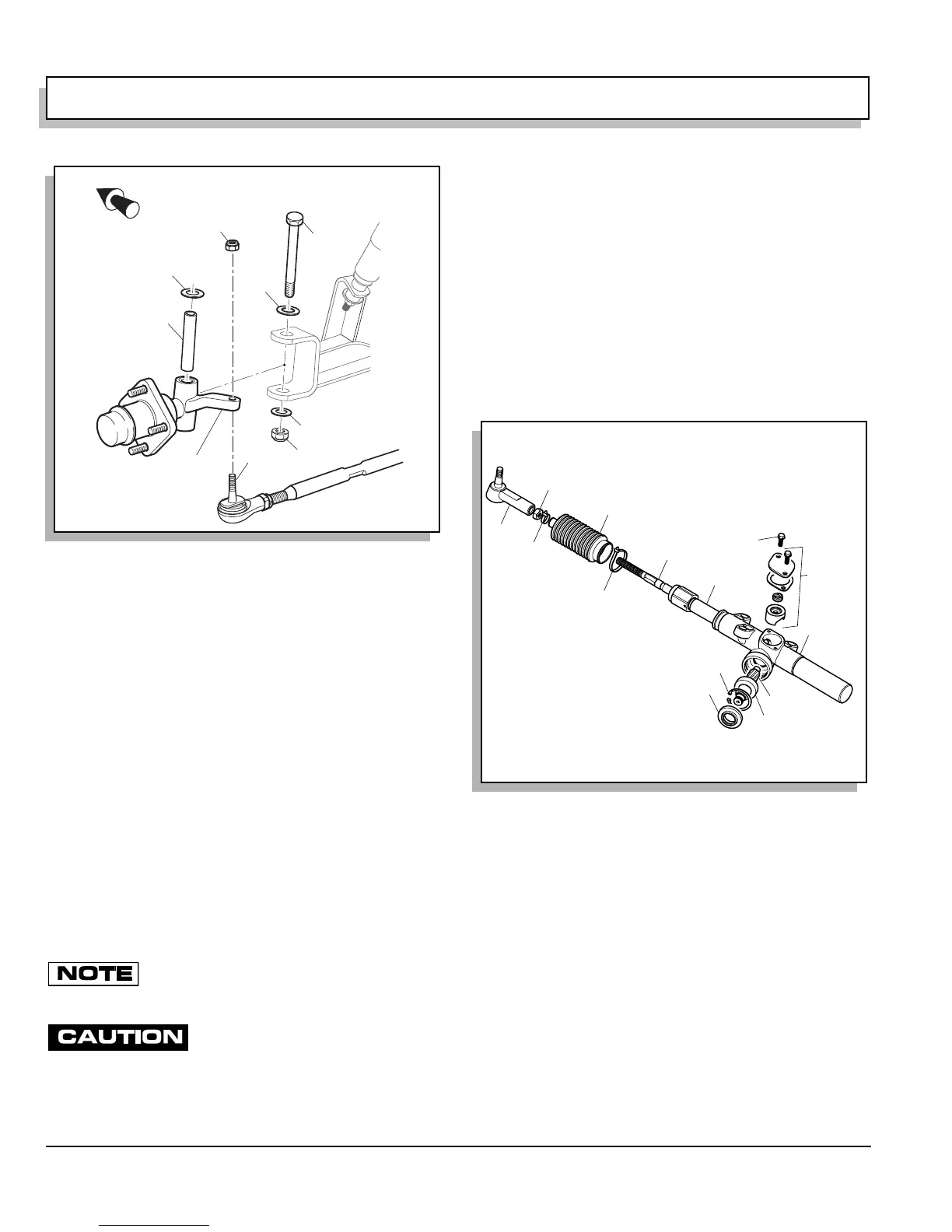

Disassemble rack and pinion unit (1) by first removing

screw (13) and tensioner (2) to relieve pressure on rack

(3) and pinion (4) (Ref Fig. 19 on page E-14). Loosen jam

nut (5) and remove rack ball joint (6) from rack extension

(7). Cut wire ties (8, 14) securing bellows (9) and slide

bellows off rack extension. Pull rack (3) from unit (1).

Remove pinion seal (10). See ‘Pinion Seal Replacement’

on page E-12. Remove internal retaining ring (11) from

rack and pinion unit and pull out pinion (4) and ball bear-

ing (12) as an assembly.

Clean rack, pinion and housing. Inspect gear teeth, bear-

ing surfaces and grease seal surfaces of rack and pinion

for excessive wear or damage. If any is found, the rack

and pinion unit must be replaced as an assembly. See

‘Rack and Pinion Unit Replacement’ on page E-15.

If rack and pinion pass inspection, clean them, tensioner

and housing thoroughly and lubricate for assembly. Use

grease specified in tool list.

Assemble rack and pinion unit by first installing pinion in

reverse order of removal making sure to lubricate pinion

seal lip prior to installing seal. See ‘Pinion Seal Replace-

ment’ on page E-12. Insert rack into rack and pinion unit.

Turn pinion clockwise to help pull rack in if necessary.

Install bellows and secure to rack extension with wire tie

(8). Do not secure large end of bellows to rack and pin-

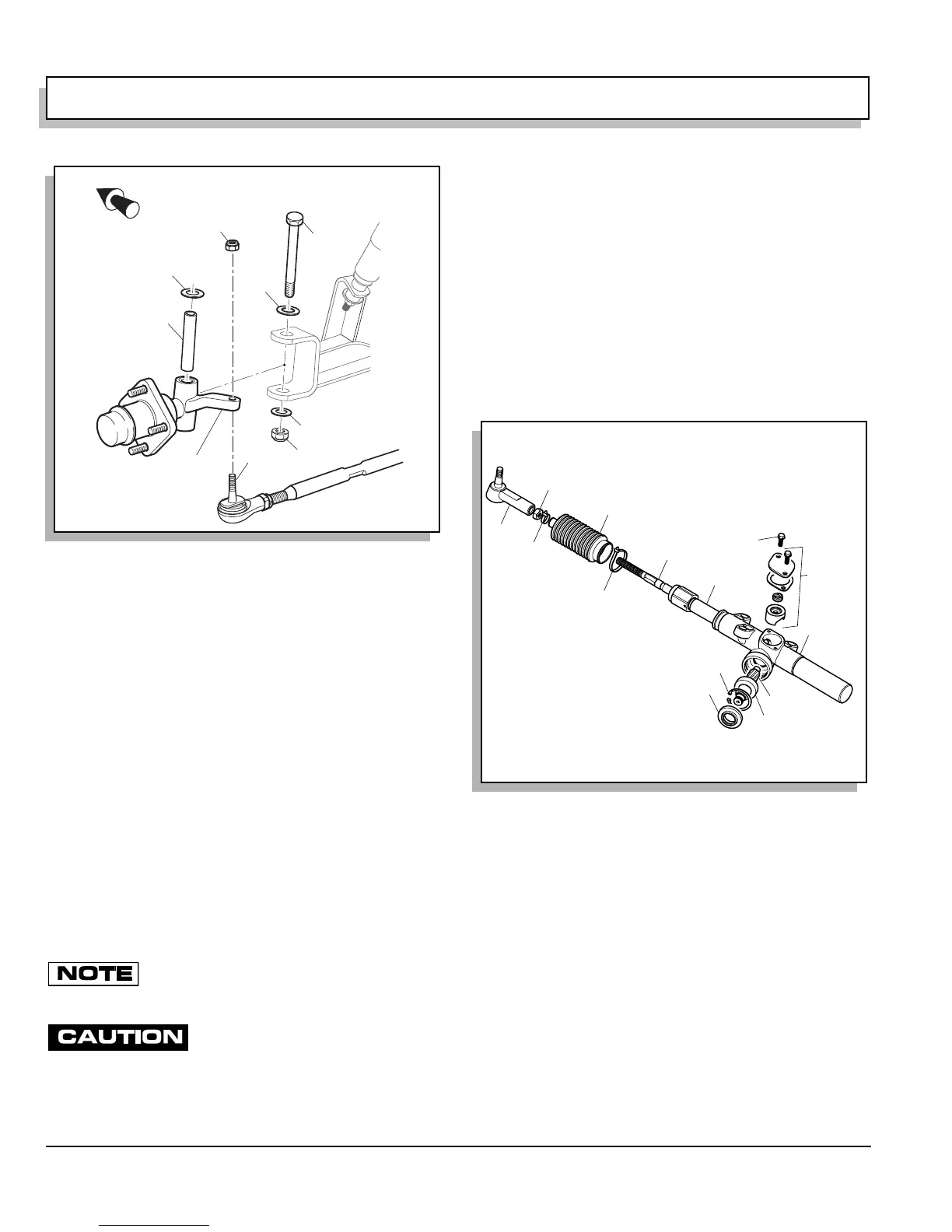

Fig. 18 Spindle Replacement

Front of Vehicle

7

5

9

10

3

2

4

8

6

Fig. 19 Rack and Pinion Unit Disassembly

10

11

12

1

2

3

8

9

6

5

7

4

13

14

Loading...

Loading...