FRONT SUSPENSION AND STEERING

Page E-3

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

the bearing is removed for inspection. It is recommended

that a bearing packer attached to a grease gun be used;

however, manual packing is acceptable if done correctly.

To pack a bearing manually requires that a dab of grease

be placed in the palm of the hand and the bearing be

dipped in the grease. Force the grease up through and

around all of the rollers until the entire bearing is satu-

rated in grease.

Assemble hub and install on spindle. See ‘Hub Replace-

ment’ on page E-8.

Once hub is placed onto spindle and before

outer wheel bearing is installed, fill the area

between the inner and outer wheel bearings about 1/2 - 3/4 full

with grease.

Wheel Bearing Adjustment

Tool List Qty. Required

Socket, 1 1/2", 1/2" drive............................................. 1

Ratchet, 1/2" drive....................................................... 1

Torque wrench, 1/2" drive, ft. lbs................................. 1

Adapter, 3/8" drive to 1/2" ........................................... 1

Torque wrench, 3/8" drive, in. lbs................................ 1

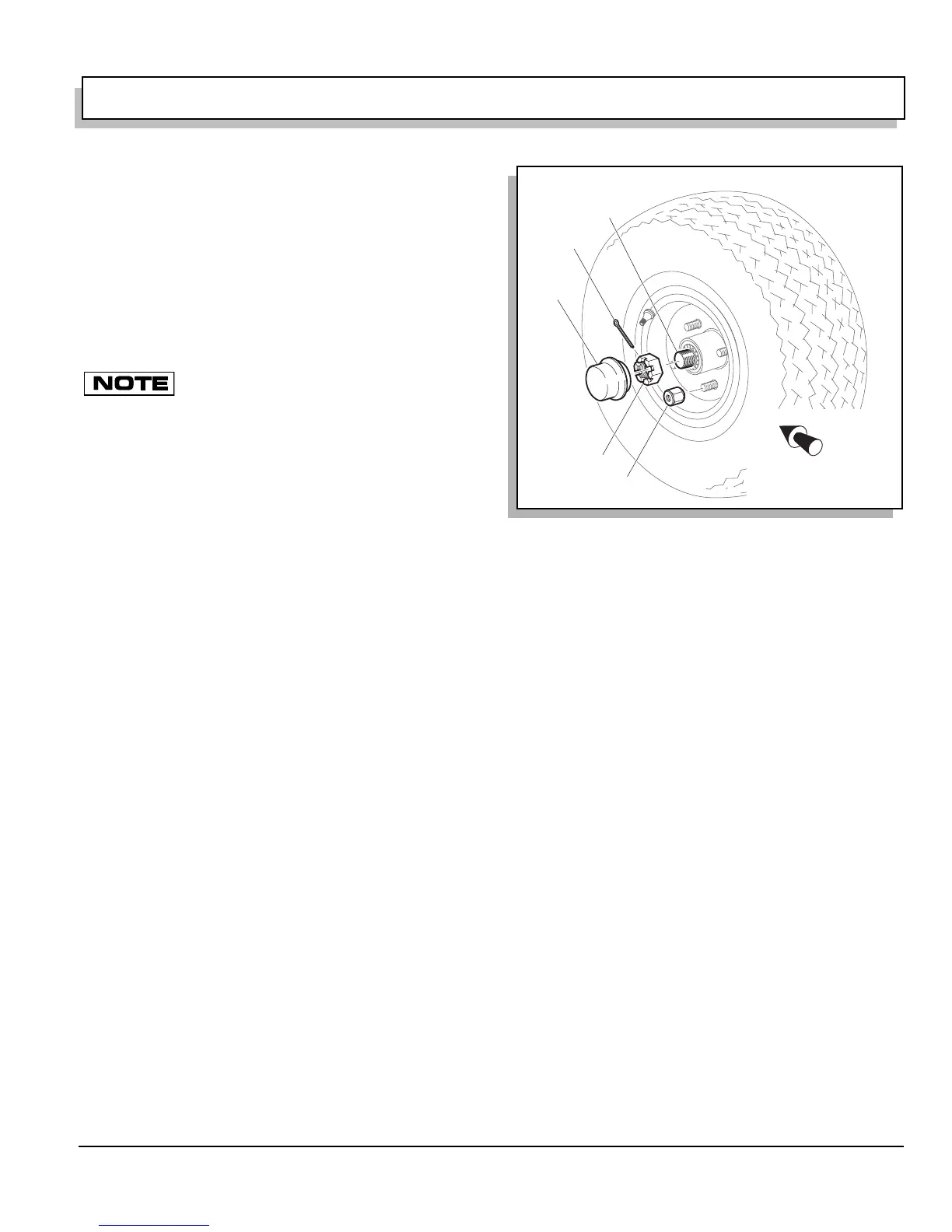

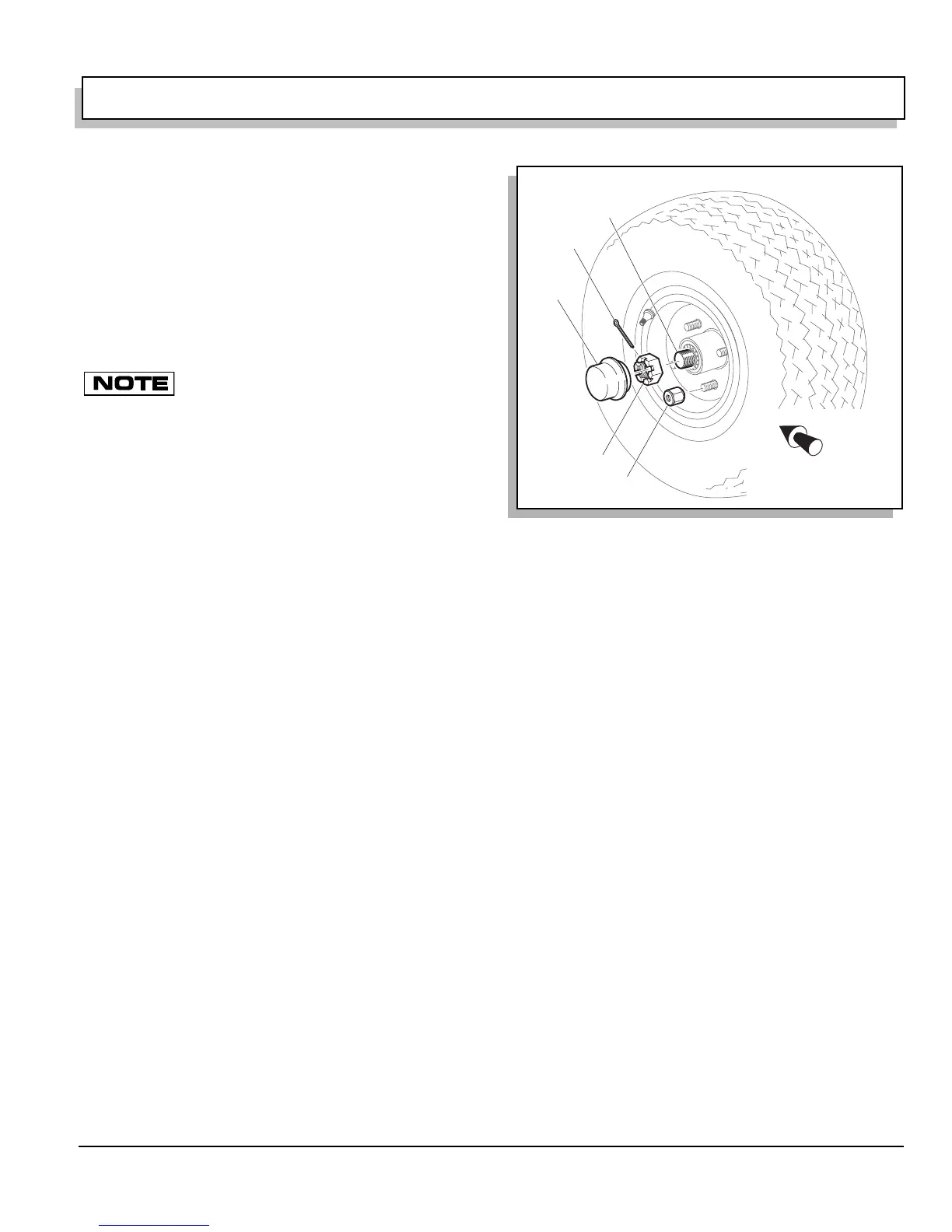

If performing a wheel bearing adjustment only, lift and

support front of vehicle per SAFETY section. Remove

dust cap (1) and cotter pin (2) and loosen castellated nut

(3).

If performing a wheel bearing adjustment as part of

another procedure, make sure wheel is mounted to hub

hand tight with lug nuts (4) and hub is loosely retained on

spindle (5) with castellated nut (Ref Fig. 3 on page E-3).

Seat bearings by rotating wheel while tightening castel-

lated nut until slight resistance is felt.

Rotate the wheel 2 - 3 more turns to displace excess

grease. If required, tighten castellated nut (3) again until

slight resistance is felt. If the cotter pin hole in the spindle

(5) aligns with a slot in the castellated nut, insert a new

cotter pin (2). If the hole does not align, the castellated

nut must be loosened to align with the closest available

slot in the nut.

Check for smooth and free rotation of the wheel and an

absence of play when the wheel is grasped by the out-

side of the tire. Bend the cotter pin (2) against the flats of

the castellated nut (3).

Replace the dust cap (1) and lower vehicle per SAFETY

section.

If completing a wheel bearing adjustment as part of

another procedure, tighten front wheels per WHEELS

AND TIRES section.

Wheel Alignment

Tool List Qty. Required

Tape measure.............................................................. 1

Chalk ........................................................................... 1

Wrench, 9/16".............................................................. 1

Wrench, 3/4"................................................................ 1

Crowfoot socket, 3/4", 1/2" drive ................................. 1

Torque wrench, 1/2" drive, ft. lbs. ................................ 1

Socket, 13 mm, 3/8" drive ........................................... 1

Ratchet, 3/8" drive....................................................... 1

Torque wrench, 3/8" drive, in. lbs. ............................... 1

Lift the front of the vehicle and support on jack stands as

per SAFETY section. Confirm the alignment of the front

springs. See ‘Front Spring Replacement’ on page E-6.

Rotate each wheel and scribe a chalk line around the cir-

cumference of the tire at the center of the tread pattern.

Lower vehicle and, with tires in the straight ahead posi-

tion, roll it forward approximately five feet in order to

allow the tires to take their normal running position.

Measure the distance between the chalk lines at both the

front and rear of the tires (Ref Fig. 4 on page E-4). The

measurement taken at the front of the tires should be 0" -

1/8" (0 - 3 mm) less than the rear.

Fig. 3 Bearing Adjustment

3

1

2

4

5

Front of Vehicle

Loading...

Loading...