N

REAR AXLE

Page N-1

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

Rear Axle Removal

The rear axle assembly is

top heavy. To reduce the

possibility of personal

injury while removing the rear axle, be sure to support

the axle and motor assembly when removing the

springs.

If no lifting device is available, a second person

should hold the motor in the correct position until the

springs are removed. Both persons should remove

the rear axle and motor assembly.

Disconnect the negative (BL-) battery cable with an

insulated wrench before attempting to remove wires

from the motor (see safety procedures in SAFETY

section of this manual). The shorting of motor wires

could cause an explosion.

Disable the electrical system to the motor by turning the

key switch to the ‘OFF’ position and disconnect negative

(-) battery cable from the battery.

Remove the wires to the motor, being careful to prevent

the axle assembly from rotating, remove the bottom

shock mounting hardware and the springs from the rear

axle as detailed elsewhere in the REAR SUSPENSION

section.

Disconnect brake cables at rear wheel and axle bracket.

The rear axle and motor assembly can now be lifted from

the jack stands and lowered to the floor.

To remove the rear axle assembly will require

the use of an overhead hoist that can support

the motor. The position of the motor will cause the rear axle

assembly to rotate when the ‘U’ bolts (7) are removed. If no

hoist is available, the motor may be held in position by a second

person. With the springs removed, both persons can lift the

entire assembly from the jack stands and lower it to the floor.

Rear Axle Installation

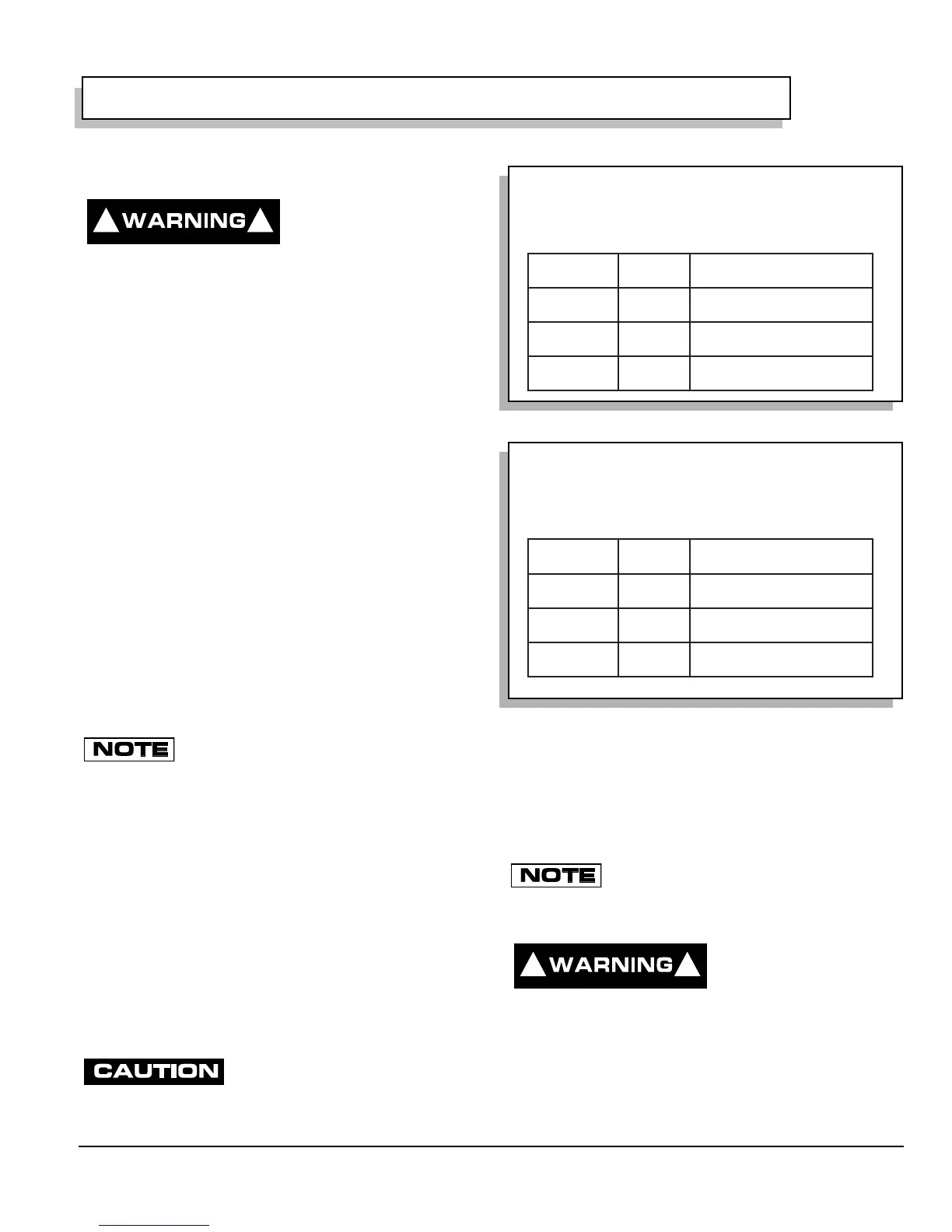

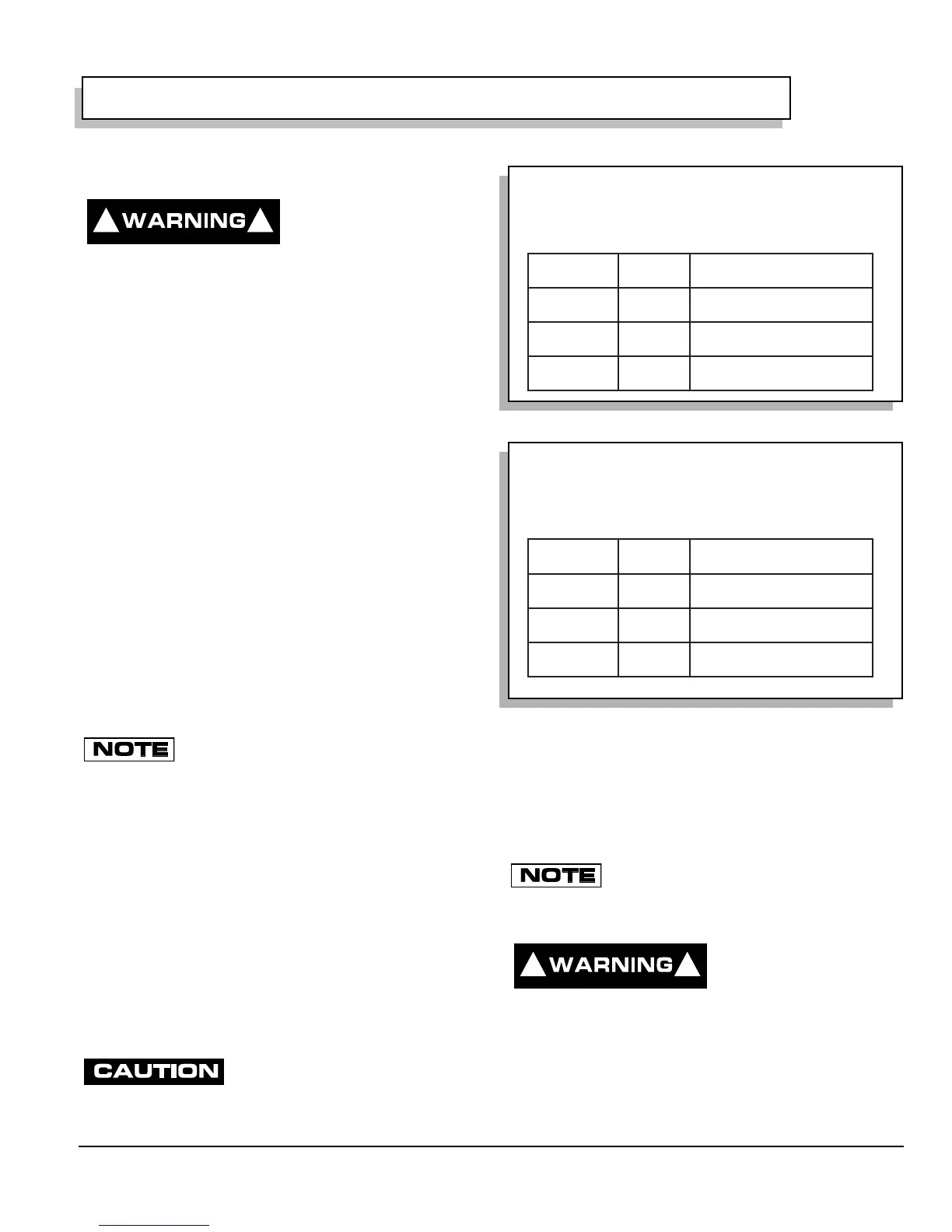

Installation is in the reverse order of removal. Tighten

motor terminal hardware to 66 in. lbs. (8 Nm) torque (Ref

Fig. 1 on page N-1)(Ref Fig. 2 on page N-1).

Install new cotter pins.

REAR AXLE DISASSEMBLY

The rear axle is a precision assembly,

and therefore any repair or replacement

of parts must be done with extreme care in a clean environment.

Before attempting to perform any service on the axle, read and

understand all of the following text and illustrations before dis-

assembling the unit.

Handle all splines with extreme care.

Snap rings must be removed/installed with care to prevent dam-

age of bearings, seals and bearing bores.

It is recommended that whenever a bearing,

seal or ‘O’ ring is removed, it be replaced with a

new one regardless of mileage. Always wipe the seals and ‘O’

rings with a light oil before installing.

To reduce the possibility

of personal injury, follow

the lifting procedure in

SAFETY section of this manual. Place wheel chocks

in front and behind the front wheels and check the

stability of the vehicle on the jack stands before start-

ing any repair procedure. Never work on a vehicle that

is supported by a jack alone.

! !

Fig. 1 Motor Wiring - 36 Volt

Fig. 2 Motor Wiring - 48 Volt

MOTOR

TERMINAL

WIRE

MARKER

FROM

A1

A2

S1

S2

A1

A2

S1

S2

Direction Selector "D"

Direction Selector "B"

Direction Selector "C"

Controller "M-"

36 VOLT MOTOR WIRING

MOTOR

TERMINAL

WIRE

MARKER

FROM

A1

A2

S1

S2

A1

A2

S1

S2

Direction Selector "D"

Direction Selector "B"

Controller "B+"

Controller "A2"

48 VOLT MOTOR WIRING

! !

Loading...

Loading...