TABLE

4

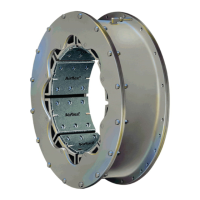

- MAXIMUM SAFE OPERATING SPEEDS

Size (Narrow)

Maximum RPM

11.5VC500

1800

14VC500

1500

16VC600 1400

20VC6OO

1200

24VC650

1050

30

l

3.1

3.1.1

3.1.2

VC 5000

Size (Narrow) Maximum RPM

28VC650

1000

33VC650

35VC650

900

37VC650

800

42VC650

OPERATION

Warning:

Exceeding the operating limits

described in this section may result in

personal injury or equipment damage.

Torque, RPM and Pressure Limits

The developed torque is directly proportional

to the applied air pressure. If the developed

torque seems inadequate, check for oil,

grease or dust contamination.

Caution:

Maximum applied air pressure is 125

psig (8.5 bar). Operation at pressures

exceeding 125 psig may result in

damage to the element. Consult the

factory if operation at pressures

greater than 125 psig is desired.

Caution:

The non-asbestos friction material

used in Airflex VC units may not

develop rated torque initially, as a

short “wear in” period is required. It is

very important that clutch or brake

operation be monitored closely to

prevent excessive heat generation

from slippage.

Maximum safe operating speeds are shown on

Table

4.

Danger:

Do not exceed the operating speeds

shown on Table 4. Operation at

speeds greater than allowable will

result in permanent damage to the

element, personal injury or death.

Size (Wide)

Maximum RPM

14VC1000

1800

16VC1000 1400

20VC1000

1300

24VCl000

1250

28VC1000 1100

32VCl000

1050

38VC1200

740

Size (Wide)

42VC1200

46VC1200

52VC1200

51VC1600

60VC1600

66VC1600

Maximum RPM

670

550

550

520

520

4.0 MAINTENANCE

Warning:

Only qualified personnel should main-

-

tain and repair these units. Faulty

workmanship may result in personal

injury or equipment damage.

Caution:

When replacing clutch or brake

components, use only genuine,

Airflex replacement parts.

41

l

Periodic Inspection

4.1.1

The following items may be inspected without

disassembly of the element:

4.1.1.1

Friction Shoe Assembly Lining Wear -

Check the lining thickness and compare to the

values shown on Table 5. If the linings have

worn to minimum allowable thickness or less,

they must be. replaced as a complete set.

Caution:

Operation with friction material worn

to less than minimum allowable thick-

ness will result in damage to the

drum.

Note: A wear indicating groove (see figure

below) is provided on each end of the friction

block. The maximum wear point, which coin-

cides with the values shown on Table 5, is at

the bottom of the groove.

II

psqg\

fYjgg

G

Copyright Eaton Corp., 1989. All rights reserved.

Revised: July, 1995 (PDF format)

Loading...

Loading...