Do you have a question about the Eaton RVAC and is the answer not in the manual?

Detailed overview of the RVAC indoor fixed AC metal enclosed switchgear, its development, and applications.

Specifies the environmental and atmospheric conditions for safe and optimal operation of the switchgear.

Explains the structure and meaning of the product's catalogue numbering system for identification.

Presents key technical specifications and rated values for the switchgear, including voltage and current ratings.

Details fuse selection based on transformer capacity and rated current for protection.

Lists relevant national and international standards the product complies with for quality assurance.

Guidelines for safe transportation, loading, and unloading of the switchgear to prevent damage.

Procedures for visual inspection, SF6 gas pressure check, and proper storage of the equipment.

Provides dimensional data for various RVAC RMU models for installation planning and site preparation.

Describes the requirements and construction of the RMU installation base, including concrete pouring.

Instructions on securely fixing the RMU to the base frame using bolts and specified torque.

Details the procedure for connecting the RMU to the site's grounding grid for safety.

Steps for preparing and connecting cables to the RMU compartments, ensuring proper sealing.

Procedure for installing and replacing fuses in the combination unit, including safety precautions.

Method for connecting multiple switchgear cabinets using a bus connector to form a ring.

Final checks and cleaning required after installation is complete to ensure proper function.

Instructions for operating the load switch cabinet, covering interface description and interlocks.

Instructions for operating the combination unit, including interface description and interlocks.

Instructions for operating the circuit breaker cabinet, covering interface description and interlocks.

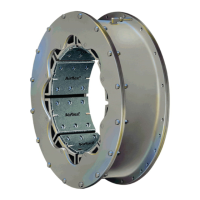

Overview of different RVAC cabinet configurations and their specific functions and features.

Pre-operation checks and guidelines for safe and correct operational startup of the RMU.

Safety precautions and procedures for managing SF6 gas density and pressure within the enclosure.

Routine visual checks on equipment condition and indicators during operation on a daily/weekly basis.

Periodic external inspection and maintenance performed when the RMU is stopped for running.

Detailed external inspection and maintenance performed at longer intervals when RMU is stopped.

Maintenance performed due to exceptional situations or when operational limits are reached.

Tests conducted after repair to ensure equipment integrity, seal tightness, and withstand voltage.

| Brand | Eaton |

|---|---|

| Model | RVAC |

| Category | Industrial Equipment |

| Language | English |