Instruction Leaflet IL0102002E

Effective April 2018

Ring Main Unit Operation Instruction

14 EATON CORPORATION www.eaton.com

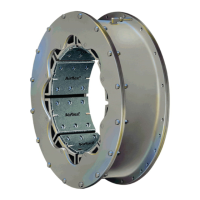

Figure 10.1 Forklift handling example

Figure 10.2 Crane handling example

1. Transport and handling

Chapter 2 Transport, handling,

inspection and storage

1.1. The switchgear must be transported under the conditions that

the load switch is in “OFF” position, with its charging device

in “energy-releasing” state and the ground switch in “closed”

state.

1.2. The outer packing of the switchgear shall have anti-shock,

moisture-proof and dust-proof performance, and be adaptable

to railway and highway transportation.

1.3. In the case of handling by hand-push type forklift or by freight

forklift, the switchgear should be put onto the transportation

pallet (see Figure 10.1). In the case of crane handling, the

lifting hook of the crane should be hooked into the two lugs

on the top of the switchgear. The angle between the lifting

rope and the top of the cabinet shall exceed 45° (the angle

between the lifting rope and the plumb line shall not exceed

45 °), so as to avoid any deformation to the cabinet or the lug

(see Figure 10.2).

2. Inspection and storage

2.1. Visual inspection

Users shall make open-box inspections in a timely manner

after receiving the goods, to check the equipment for any

damages or deformation during transportation.

2.2. SF6 gas pressure inspection

When the product is delivered from the factory, SF6 gas has

been filled, with the gas relative pressure of 0.03 MPa. During

on-site inspection, the gas density meter will indicate whether

the pressure of the gas is normal (normal when the pointer

points to the green area, and abnormal when pointing to the

red areas).

2.3. Accessory inspection

After unpacking the package, please check whether the

equipment’s primary scheme conforms to the requirements

of the order, and whether the accessories are complete, such

as the equipment’s factory data, special opening tools, and

spare parts. In the case of any errors, please contact the

After-sales Service of Cooper Electric in a timely manner.

2.4. Storage

If the equipment can not be installed in time and has to be

stored for a period of time, use the original packaging

materials to properly pack the equipment after open-case

inspections, and store the equipment in a dry and clean place,

to avoid any mechanical damages to the equipment.

1.4. During loading and unloading, the switchgear shall be handled

according to the storage and transport indication mark on the

package, to avoid equipment damages. In general, the

switchgear should be moved vertically, to prevent from tilting

or turning over.

1.5. In the case of any damages found on the switchgear after

long-distance transportation, notify the cargo division

immediately to have the damage accidents identified.

CAUTION

IN THE CASE OF ABNORMAL GAS PRESSURE, NOTIFY THE AFTER-SALES

SERVICE OF COOPER ELECTRIC IN A TIMELY MANNER FOR DULY AND

PROPER HANDLING.

CAUTION

CHECK THE WEIGHT OF THE SWITCHGEAR. DO NOT USE WORN OUT

AND DAMAGED STEEL ROPES OR LIFTING RINGS. DO NOT USE THE

LIFTING EQUIPMENT WITH THE LIFTING CAPACITY LESS THAN THE

WEIGHT SHOWN ON THE NAMEPLATE OF THE SWITCHGEAR.

Loading...

Loading...