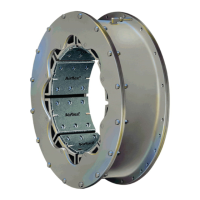

Rubber

Sleeve

Long

Air Tube

Spacers

Fig. 11

2.7.1.2

2.6.6

Align the air connections and reassemble the

element halves, making sure the spacers are in

place between the elements. See Figure

11.

2.6.7

Reassemble the air connection tubes. If an

elbow has been removed, use a good quality

pipe sealant on the threads. See Figure

11.

Note: The elbow assemblies on the outboard

element (farthest from the spider) use rubber

compression sleeves. Make sure the sleeves

are securely on the long air tubes.

2.6.8

Install the air connection gaskets onto the

air tubes. The metal backup washer is to be

positioned toward the elbow (away from the

spider). See Figure IO.

2.6.9

Align the element air connections with the

corresponding passages in the spider and

attach the element to the spider with the

appropriate fasteners. See Table

1.

Make sure

the element fully engages the register in the

spider.

A

! Warning:

Use only the proper grade and num-

ber of fasteners. Using commercial

grade fasteners (Grade

2)

in place of

Grade

8

fasteners may result in failure

of the fasteners under load, causing

personal injury or equipment damage.

m

/ Rotorseal Pressure

fSolenoid Valve

Switch

\

--iii--

27

.

2.7.1

2.7.1.1

2.7.1.3

2.7.1.4

2.7.1.5

2.7.1.6

2.7.1.7

Air Control System

A typical air control system is shown on

Figure 12. Since the air control system used

will be dependent on the specific application,

a detailed description cannot be made in this

manual. Following are some general

guidelines for installing and adjusting air

controls.

The air receiver tank must be located as close

to the rotorseal as possible (within five feet) for

consistent clutch or brake response.

Use full size piping and valves consistent with

the rotorseal size.

Keep the number of elbows to a minimum.

Use poppet-type solenoid valves. Spool

valves are not recommended.

An air line lubricator is not required for the

element; however, if one is used, it must be a

non-adjustable, mist-type.

If a flow control valve is used, it must have free

flow (indicated by an arrow on the valve body)

directed away from the element.

The final connection to the rotorseal MUST be

made with flexible hose and place no radial

load upon the rotorseal.

Caution:

Do not use rigid pipe at the connec-

tion to the rotorseal. Rigid piping

will result in excessive loads on the

rotorseal bearings, shortening life.

Caution:

Maximum applied air pressure is

125

psig

(8.5

bar). Operation at pressures

exceeding 125 psig may result in

damage to the element. Consult the

factory if operation at pressures

greater than

125

psig is desired.

Pressure

Pressure

Relief Valve

/

Switch

Regulator\

/

KTank

Drain

Filter

/

Fig. 12

10

@

Copyright Eaton Corp., 1989. All rights reserved.

VC 5000

Revised: July, 1995 (PDF format)

Loading...

Loading...