4.1.2.3

Friction Shoe Lining Wear

- If the linings are

glazed, they may be lightly sanded to remove

the glazing PROVIDING THEY DO NOT CON-

TAIN ASBESTOS.

Warning:

Clean the edge of the lining and note

the presence of a blue stripe and a

white stripe along with brass flakes in

the friction material. If the above ex-

ists, the linings contain asbestos.

Using the appropriate precautions for

working with asbestos, remove the

linings and dispose of properly. DO

NOT ATTEMPT TO SAND FRICTION

MATERIAL CONTAINING ASBESTOS.

Caution:

When working with any friction

material, regardless of whether or

not it contains asbestos, always wear

approved safety equipment.

4.1.2.4

Uneven Friction Lining Wear

- Tapered wear

across the friction surface typically indicates a

worn drum and/or misalignment. If two or

more adjacent shoes are worn on one end

only, the air actuating tube has most likely

developed a ply separation at that location.

4.1.2.5

Backing Plate Wear

- Wear on the ends of

the backing plates from bearing against the

side plates is indicative of misalignment or

thrusting. If wear is on one end only, and

uniform for all backing plates, a worn drum

may be causing the shoes to thrust as the

element engages. If wear exists on both ends

of all of the backing plates, excessive misalign-

ment is probably the cause. Slight notching in

the torque bar cavity is normal; however, if the

notching occurs in a short amount of time,

check shaft alignment. If both walls in the

torque bar cavity are notched, there may be

a significant vibration (torsional) problem.

4.1.2.6

Release Springs and Torque Bars -

Exces-

sive wear at the ends of the torque bars where

the release spring rides indicates excessive

parallel misalignment.

4.1.2.7

Side Plates

- Any wear on the backing plates

will also be reflected as elongation of the

torque bar holes in the side plates.

VC 5000

Revised: July, 1995 (PDF format)

4.1.2.8

4.1.2.9

42l

4.2.1

4.2.2

4.2.3

4.2.4

43

l

4.3.1

13

.

Contamination of Friction Shoes

- Mild oil or

grease contamination may be removed with a

solvent. Linings which have become saturated

must be replaced. Also, linings that have been

charred from excessive heat must be replaced.

n

! Caution:

When using any solvent, always

follow the appropriate safety

precautions.

Excessive Dust Accumulation

- If dust

becomes packed in the backing plate

cavities, a pressurized enclosure should be

considered. Excessive accumulations will

prevent complete shoe retraction.

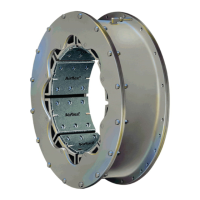

Removal of Element Assembly and

Drum (Narrow, Dual Narrow and

Single Wide)

A

! Warning:

Prior to removal of the clutch or

brake, make sure the machinery is in,

and will remain in, a safe condition.

Match mark the element to the spider and the

drum to the drum hub.

Discon

nect the el

ement from

allow it to rest on the drum.

the spider

and

Connect an overhead support to the element

and apply enough tension to support the

weight of the element and drum.

Remove the fasteners attaching the drum to

the drum hub and hoist the element/drum out

from between the shafts.

A

! Caution:

Use extreme care when disconnecting

the drum from the hub. Shear points

exist at the mounting holes.

Removal of Element Assemblies

and Drums (Dual Wide)

Match mark the element assemblies to each

other and to the spider. Also, match mark the

drums to each other and to the drum hub.

@

Copyright Eaton Corp., 1989. All rights reserved.

Loading...

Loading...