/-

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.3.7

44

.

4.4.1

Disconnect the dual element from the spider

and allow it to rest on the drums. Remove the

air connection tubes.

Remove the fasteners and spacers attaching

the element halves together.

Attach an overhead support to the spider side

element and apply enough tension to support

the weight of the element half and one of the

drums.

Remove the through bolts and nuts attaching

the drums to the drum hub. DO NOT REMOVE

THE SHORT SCREWS AND LOCKWASHERS

WHICH HOLD THE FEMALE DRUM ONTO

THE DRUM HUB. Carefully hoist the spider-

side element and drum out from between the

shafts.

Attach an overhead support to the remaining

element and apply enough tension to support

the weight of the element and drum.

Remove the short screws and lockwashers

holding the drum onto the drum hub and

carefully hoist the element and drum out from

between the shafts.

A

! Caution:

Use extreme care when disconnecting

the drums from the drum hub. Shear

points exist at the mounting holes.

Removal of Spider and Drum Hub

Puller holes are provided for removal. It will

usually require heating along with the puller.

When heating, heat uniformly to prevent hot

spots.

Snap ring and Counterbore Eliminated

45

.

4.5.1

4.5.2

4.5.3

4.5.4

4.5.5

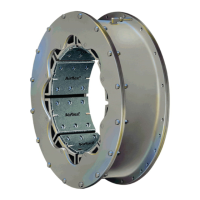

11.5VC500 24VC650

42VC650

24VCl000

14VC500

28VC650

14VCl000 28VC1000

16VC600

33VC650 16VCl000 32VCl000

20VC600 37VC650

20VC1000

Fig. 13

Disassembly of the Element

Lay

the element flat on a clean work surface.

Remove the side plate and clean for reassemb-

ly. If the torque bar holes are elongated more

than one-half the diameter of the pin on the

end of the torque bar, the side plate must be

replaced.

Remove the friction shoe assemblies, torque

bars and release springs. If the torque bars

and springs come out of the element with the

friction shoe assemblies, carefully tap them

out of the backing plate cavities. Note wear

and replace as necessary.

A

! Caution:

Whenever the element is removed

and disassembled, it is always good

practice to replace the release

springs.

Remove the air connection elbows and spiral

snap rings which secure the air actuating tube

to the rim. Smaller size elements do not use

snap rings. Carefully remove the air actuating

tube from the rim and thoroughly inspect.

Replace if necessary.

Note: The snap rings may no longer be re-

quired on certain size elements. Also, rims

manufactured before

1984

were counterbored

at the tube valve hole to accept the snap ring.

This counterbore has been eliminated, and a

second snap ring groove has been added to

the tube valve. See Figure

13.

Remove the remaining side plate only if it is to

be replaced.

Counterbore Eliminated and Second

Snap Ring Groove Added

. ,,

38VCl200 46VCl200

5lVCl600

42VCl200 52VCl200 60VCl600

66VCl600

14

0

Copyright Eaton Corp., 1989. All rights reserved.

VC 5000

Revised: July, 1995 (PDF format)

Loading...

Loading...