46

.

4.6.1

4.6.2

4.6.3

47

.

4.7.1

4.7.2

4.7.3

Friction Lining Replacement

Caution:

Use only genuine Airflex replacement

parts.

Make sure the torque bars and release springs

have been remove from the backing plates.

For riveted friction shoe assemblies, drill

the rivets with a

15/64”

(6mm) drill and tap the

rivet body out. Larger elements have linings

attached with flat head screws and locknuts.

Air-flex special wrench p/n

304572

will aid in

holding the locknuts during removal. See

Table 7.

TABLE

7

FRICTION SHOE ASSEMBLY FASTENERS

DRIVE PIN RIVETS

11.5VC500 24VC650 42VC650 24VCl000

14VC500 28VC650 14VCl000 28VC1000

16VC600 33VC650

16VC1OOO

2OVC600 37VC650 2OVC1OOO

FLAT HEAD SCREWS* (BRASS)

AND LOCKNUTS

32VCl000 42VC1200 52VC1200 6OVC1600

38VC1200 46VC1200 51VC1600 66VC1600

* Screws are 3/8-16NC-2 x 1.25 long flat head

4.7.4

Carefully insert the air actuating tube into the

rim. Push the valves on the tube through the

corresponding holes in the rim and install the

spiral snap rings (if applicable).

4.7.5

Place a torque bar in each mating hole in the

side plate, slide a friction shoe assembly onto

each torque bar and carefully tap a release

spring (51VC1600,60VC1600 and 66VC1600

elements have two release springs in each

cavity) into place. Make sure the spring is

positioned on the side of the torque bar

opposite the friction lining. Also, the spring

must contact the torque bar at two points, not

one. See Figure 15.

Tube

Backing

-Release

k

Spring

4.7.6

4.7.7

Attach the new lining to

the backing plate with

new screws and locknuts

or drive pin rivets (See

Figure 14), as applicable.

Work from the center of

the friction lining out to

the ends. The rivets are

installed by driving the pin

flush with the head.

.

14

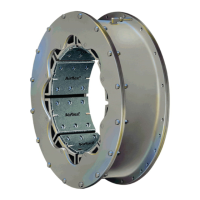

Assembly of the Element

Make sure that all of the components have

been cleaned and any damaged or worn com-

ponents have been repaired or replaced.

Assemble one of the side plates to the rim

with cap screws and lo&washers. It is not

necessary to install through bolts and locknuts

at this time.

Lay the rim/side plate assembly on a clean, flat

work surface, side plate down.

VC 5000

Revised: July, 1995 (PDF format)

)

/Plate

4.7.8

4.7.9

4.7.10

4.7.11

Reinstall per 2.0.

15

\

Torque

Bar

Fig. 15

Lay the remaining side plate in position so the

air connections and torque bar holes are

properly aligned.

Carefully guide the torque bars into the cor-

responding holes in the side plate. It is often

helpful to install four equally spaced screws

and nuts through the rim and side plate to

keep some tension on the side plate

throughout this step.

Attach the side plate to the rim with cap

screws and lockwashers, making sure all of

the torque bars are seated in their side plate

holes.

Note the orientation of the air connections

and install the through bolts and locknuts

where applicable.

Reinstall the elbows (or quick release valves),

using a good quality sealant on the pipe

threads. Install the air connections on single

narrow, dual narrow and single wide elements.

Install only the short air connections (element

closest to spider) on dual wide elements.

0

Copyright Eaton Corp., 1989. All rights reserved.

Loading...

Loading...