23

.

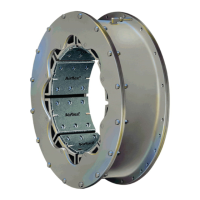

Mounting Spider and Drum Hub

2.3.1

The spider and drum hub are bored for a

press fit onto their respective shafts. The inter-

ference is approximately .0005 in. per inch

(.0005mm/mm) of shaft diameter.

2.3.1 .1

Ensure the shaft is clean and free of nicks or

burrs and check the shaft and bore diameters

for proper fit.

2.3.1.2

Tap the key into the keyway, making sure it

bottoms.

2.3.1.3

Apply a light coat of anti-seizing compound to

the shaft and key.

2.3.1.4

Heat the drum hub or spider uniformly to

25O*F

(121*C)

to expand the bore.

1

n

! Caution:

It is recommended the drum hub

or spider be heated in oil or an oven;

however, since this is not always

possible, torches may be used. When

using torches, use several with

“rosebud” (broad-flame) tips and keep

them moving to avoid “hot spots”.

Check bore temperature frequently to

avoid overheating.

2.3.1.5

Slide the heated drum hub or spider onto the

shaft until the hub face is flush with the end of

the shaft. Hold in position and allow to cool.

24

.

Shaft Alignment

Note: The text in this section applies to gap-

mounted applications; however, the alignment

tolerances apply to all types of mountings.

Parallel Alignment Tolerance

(Off set):

Not to exceed 0.010 inch (.254mm) Total

Indicator Reading (0.005 in. (.127mm)

maximum offset).

Angular Alignment Tolerance (Gap):

Not to exceed 0.0005 inch per inch

(.0005mm/mm) diameter at which readings

are taken ("D” on Fig. 9).

Note: The alignment procedure described

below has been used successfully on many

VC clutch and brake applications. Other

procedures, of course, may be used; however,

the alignment tolerances are the same regard-

less of the technique used.

Foundations must be set so distance "X”,

shown on Figure 9, is established. If the clutch

is mounted on a shaft having plain bearings,

make sure the shaft is centered within the bear-

ings when establishing the “x” dimension.

Refer to Table 2 for appropriate "X" dimensions.

Note: It is presumed that one of the shafts has

been properly located and anchored.

_*

TABLE

2

- “X” DIMENSIONS (FIG. 9)

SIZE

“X" in.

SIZE

"X" in.

SIZE

"X" in.

SIZE

"X” in.

(mm)

(mm)

(mm)

(mm)

7

0

Copyright Eaton Corp., 1989. All rights reserved.

VC 5000

Revised: July, 1995 (PDF format)

Loading...

Loading...