L

Inside Micrometer

Fig. 9

2.4.2

2.4.3

2.4.4

2.4.5

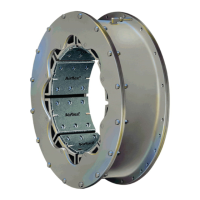

Fabricate a rigid bracket for supporting a

dial indicator and attach to the spider. See

Figure 9.

Thoroughly clean the flange O.D. and the face

of the drum hub where alignment readings are

to be taken.

Rotate the spider and take parallel alignment

readings off the drum hub flange O.D. If both

shafts can be rotated together, the alignment

readings are less influenced by any surface

irregularities.

A

! Caution:

When recording parallel alignment

readings, “sag" of the indicator/

indicator bracket must be accounted

for

.

Angular alignment readings can be made by

accurately measuring the gap between the

e

spider and drum hub faces with an inside

micrometer. If a dial indicator is used, make

sure to monitor and correct for any axial move-

ment of the shaft. To reduce the influence any

surface iregularities may have on the angular

alignment readings, index the spider 90

degrees after taking the initial set of readings.

Take an additional set of readings and index

the spider another 90 degrees. Continue in this

manner until four sets of readings have been

taken. For misalignment correction, use the

average of the four readings at each position.

In other words, average the four top readings,

the four bottom readings, and each of the four

side readings.

2.4.6

Shim and shift the base of the movable shaft to

correct the misalignment. After tightening the

base, recheck the alignment and correct if

necessary. Make sure to check for a “soft foot”

condition. Dowel or chock into position after

satisfactory alignment has been achieved.

Note: On many applications, thermal growth

of the driving or driven machinery may result

in unacceptable shaft alignment in a running

condition. It is always good practice to make a

“hot" alignment” check and re-shim if necessary.

25

l

Installation of Element and Drum

(Narrow, Dual Narrow and

Single Wide)

2.5.1

Note the orientation of the drum flange with

respect to the air connection(s) on the element

and slide the drum into the element.

2.5.2

Separate the shafts as far as the bearing

clearances will allow and hoist the ele-

ment/drum into position.

2.5.3

Attach the drum to the drum hub with the

appropriate fasteners. See Table 1

l

Make sure

the bore in the drum flange fully engages the

pilot on the drum hub.

A

! Warning:

Use only the proper grade and num-

ber of fasteners. Using commercial

.

grade fasteners (Grade 2) in place of

Grade 8 fasteners (where called for)

may result in failure of the fasteners

.

under load, causing personal injury or

equipment damage.

2.5.4

Install the air connection gaskets onto the

air tubes. The metal backup washer is to be

positioned toward the elbow (away from the

spider). See Figure

10.

Note: Some older elements use a flanged

air connection tube and a thin gasket. See

Table 3 for correct part numbers.

Fig. 10

8

@

Copyright Eaton Corp., 1989. All rights resewed.

VC 5000

Revised: July, 1995 (PDF format)

Loading...

Loading...