Do you have a question about the Eaton Cutler-Hammer ATC-300 and is the answer not in the manual?

| Brand | Eaton |

|---|---|

| Model | Cutler-Hammer ATC-300 |

| Category | Controller |

| Language | English |

Covers installation, application, operation, maintenance, and safety precautions for the ATC-300 Controller.

Explains the function of transfer switches and the role of the ATC-300 controller in ATS systems.

Describes the ATC-300 Controller as a comprehensive, multi-function, microprocessor-based ATS controller.

Defines key terminology used in the document related to ATS and controller operation.

Details the primary functions, features, and options of the ATC-300 Controller for ATS operation.

Provides an overview of the ATC-300 Controller hardware, nomenclature, and specifications.

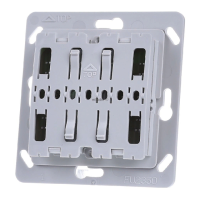

Describes the front panel components, including the LCD display, LEDs, and input pushbuttons.

Details the rear access area of the ATC-300 Controller, including connector locations and functions.

Presents a summary of the ATC-300 Controller's technical specifications in a table format.

Covers status displays, source information, time/date, history logs, setpoints, and help messages.

Explains how the ATC-300 controller operates, including input/output connections and power supply.

Details the function of various connectors (J1, J2, J3, J4, J5, J7, J8) on the ATC-300 Controller.

Provides an overview of the operation and functional use of the ATC-300 Controller.

Describes the automatic transfer and re-transfer operations dictated by features and setpoints.

Explains the special operating mode where the ATC-300 monitors sources but does not control transfers.

Details the five individual DC wetted input control signals and their definitions.

Describes the dry relay contacts used for primary control outputs and their ratings.

Covers the operating voltage range, measurements, and supercap functionality for the ATC-300.

Details the procedure and modes for performing periodic tests of the generator system.

Explains the feature for automatic programming of generator test cycles on a daily or periodic basis.

Describes the feature allowing transfer between sources with a small phase angle difference.

Explains how to access and use the device's faceplate for programming setpoints and parameters.

Introduces the programmability of the ATC-300 Controller via faceplate or communication port.

Details the procedure for entering and changing the password to access programming screens.

Explains how to view setpoints and programmed values without making changes.

Describes how to step through and change setpoint values using the front panel interface.

Lists programmable features and setpoint possibilities, referring to Table 2 for details.

Defines the scope of troubleshooting and when to replace or return the ATC-300 unit.

Provides a guide to identify problems as external or internal and offers possible solutions.

Outlines the procedural steps required to safely replace the ATC-300 controller unit.

States that the ATC-300 is self-contained and maintenance-free, intended for factory-trained personnel.

Lists and explains various display messages for status and timers used by the ATC-300 Controller.

Illustrates the operational sequence for utility to generator transfer.

Illustrates the operational sequence for transfer between two utility sources.

Illustrates the operational sequence for in-phase transition between sources.

Provides a visual representation of the ATC-300 Controller's display menu tree for navigation.

Presents voltage pickup and dropout values for undervoltage conditions at different percentages.

Presents voltage pickup and dropout values for overvoltage conditions at different percentages.

Presents frequency pickup and dropout values for underfrequency conditions.

Presents frequency pickup and dropout values for overfrequency conditions.

Loading...

Loading...