IB01602009E For more information visit: www.eatonelectrical.com

Instruction Booklet

Effective: April 2006 Page 9

ATC-300 Automatic

Transfer Switch Controller

If the LCD Display is displaying the Home screen when the Help/

Lamp Test key is pressed, all of the LED’s will momentarily illumi-

nate, then the following information will scroll across the display:

• Serial number of the ATC-300 Controller;

• Hardware revision number (= parts list revision number);

• Software version and revision number;

• Feature code – a decodable string listing all optional features

programmed in the ATC-300 Controller; and

• Firmware version.

Engine Test Pushbutton

The Engine Test pushbutton allows the user to test the Source 2

(generator) engine. The engine test function can be set with the

ATC-300 Controller to one of three setpoint modes to allow flexi-

bility in how the test is run:

0 No Load Engine Test;

1 Load Engine Test; or

2 Disabled.

The factory default is set to 1 - Load Engine Test.

For complete information on the Engine Test function, see Sec-

tion 5.7.

Step/Enter Pushbutton

The Step/Enter pushbutton allows the user to scroll through the

information and setpoint displays. By pressing the Step/Enter

pushbutton, the information on the LCD Display will advance

through the voltage(s), frequency, and status condition of Source

1, then Source 2, then the time and date information, then the

history information, then the setpoints. The information on the

LCD Display advances one step through the displayed information

cycle with each depression of the Step/Enter pushbutton.

Increase Pushbutton

The Increase pushbutton allows the user to increase the value of

the setpoints. When ATC-300 Controller is in the “Program”

Mode (to change setpoint values), each time the Increase push-

button is pressed, the value of the displayed item will increase by

one.

Decrease Pushbutton

The Decrease pushbutton allows the user to decrease the value

of the setpoints. When ATC-300 Controller is in the “Program”

Mode (to change setpoint values), each time the Decrease push-

button is pressed, the value of the displayed item will decrease

by one.

Alarm Reset Function (Increase + Decrease Pushbuttons)

Pressing the Increase and Decrease pushbuttons simultaneously

will reset the Alarm function. In addition, if both pushbuttons are

pressed simultaneously while viewing any of the historical logged

values in the program mode, the value of the current item dis-

played resets to zero.

Bypass Time Delay Function (Step/Enter + Help/Lamp Test)

Pressing the Step/Enter and Help/Lamp Test pushbuttons simulta-

neously will bypass the TDNE or TDEN functions when they

actively counting. The “Bypass TDNE/TDEN” function does not

have a user accessible, programmable setpoint for enable or dis-

able.

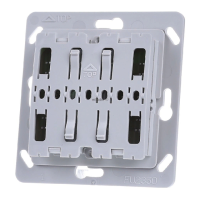

2.3 Rear Access Area

The rear access area of the ATC-300 Controller is normally accessible

from the rear of an open panel door (Figure 2).

Figure 2. ATC-300 Controller (Rear View).

All wiring connections to the ATC-300 Controller are made at the

rear of the chassis.

Note: To allow for uniform identification, the frame of reference when dis-

cussing the rear access area is with the panel door open and the User fac-

ing the back of the ATC-300 Controller.

Located at the left rear of the chassis are connectors J1, J2, and

J7. J1 and J2 provide for voltage monitoring of Source 1 and

Source 2 respectively. J7 is provided for Sources 1 and Source 2

control power input. Located at the right rear of the chassis is

the J3 programming port connector. The J4 and J5 connectors

are located at the bottom of the controller. The J4 connector

provides DC wetted connections for various control inputs. The

J5 and J8 connectors provide dry relay contacts for primary con-

trol outputs.

See Section 5.5.1 for contact ratings.

Loading...

Loading...