19

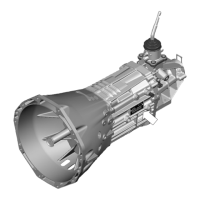

The maintenance items below must be observed to prevent fails in transmission, resulting

in unnecessary repairs that are not covered for warranty.

1. Air System and Connections

• Check daily for air leaks, worn hoses and air lines; repair immediately.

• If the vehicle has air dehumidification equipment installed check to ensure the

system is working correctly. Repair as needed.

• Check and repair air compressor as is needed. The vehicles air compressor can

allow oil to enter in the air system if not working properly.

2.

Clutch Housing Mounting

• Check all capscrews of clutch housing for looseness.

3. Clutch Release Bearing (Not Shown)

• Remove hand hole cover and check radial and axial clearance in release bearing.

• Check relative position of thrust surface of release bearing with thrust sleeve on

push-type clutches.

4. Clutch Pedal Shaft and Bores

• Pry upward on shafts to check wear.

• If excessive movement is found, remove clutch release mechanism and check the

bushing and bore and shafts for wear.

5. Lubricant

• Change at specified service intervals.

• Use only the types and grades of oils recommended.

Preventive Maintenance

Loading...

Loading...