37

PXR trip unit and communication modules

MAGNUM PXR PRODUCT GUIDE PA013006EN September 2022 www.eaton.com

3

Arcflash reduction maintenance system

The Arcflash Reduction Maintenance System/Maintenance

Mode function of the PXR trip units can reduce arc flash

incident energy that is generated on a fault condition.

This is accomplished by a separate trip circuit that, when

armed, provides a fast-acting response to the fault. This

is separate from the normal system protection setting of

instantaneous. The PXR ARMS protection operates at the

same time as the normal LSIG protection but provides a

faster immediate trip over the setting level. For most fault

conditions as shown in the time current curve below the

ARMS protection will override the protection, the normal

LSIG protection provides an added backup function.

Eaton’s Arcflash Reduction Maintenance System employs

a separate, dedicated trip circuit that results in clearing

times that are faster than standard instantaneous tripping.

This provides superior arc flash reduction to competitors’

systems that simply lower the standard instantaneous

pickup set point or employ ZSI tripping.

There are three ways to arm the Arcflash Reduction

Maintenance System/Maintenance Mode setting. One

method is locally at the trip unit front panel. Both the PXR

20 and the PXR 25 have a two-position switch on the front

of the trip unit for Maintenance Mode. Turning the switch

to the ON position will locally arm the function. The setting

for the level of reduction can be set in the trip unit menus

or by using PXPM.

For the second method of arming the Maintenance Mode

function, a remote switch or external relay contact wired

through the breaker secondary terminals can remotely arm

the Maintenance Mode protection function. A high-quality

gold-plated or palladium contact on the switch or relay is

required for this method. See Figure 34 for wiring.

A third method to arm the Maintenance Mode setting

is via a communication device, such as a Modbus RTU

controller. An Eaton Dashboard display interface module

can be used as one of the communication methods to arm

the protection function remotely from a safe distance.

The Arcflash Reduction Maintenance System setting has

six unique settings (1.5, 2.5, 4.0, 6.0, 8.0, 10.0 x I

n

) for the

pickup of the reduction setting (shown in Figure 38) is the

ARMS 1.5x active protection curve. This setting level can

be used to prevent inrush currents or load surges from

triggering the ARMS function. The new PXR trip units are

now able to go to a new lower setting of 1.5x the frame

rating I

n

for the maximum reduction of arc flash energy.

For all three arming methods, the PXR trip units provide a

local indication as a blue LED ring around the trip unit ON/

OFF switch to confirm the Maintenance Mode function

is on or off. The trip unit display will show a confirmation

screen that verifies the arming. In addition, one of the

three programmable relays in the frame module of the trip

unit can be set to indicate the status of the maintenance

mode protection. For breakers ordered with an ARMS trip

unit, relay 1 comes programmed for Maintenance Mode

Active from the factory. This normally open relay contact

allows the user to wire in an external stack light or annun-

ciator for remote indication.

The Maintenance Mode function will provide fast tripping

even when the regular Instantaneous is set to OFF. The

instantaneous LED position is also used to indicate a

trip initiated by the Maintenance Mode setting. The LCD

display, if powered, will indicate that a Maintenance Mode

trip occurred, and the unit’s trip buffer will log the event.

Figure 38. ARMS 1.5x active protection curve

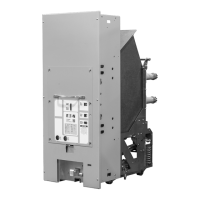

Figure 37. Maintenance mode switch

Loading...

Loading...