9

Instruction Manual IB015002EN

Effective November 2021

Pow-R-Line CS switchboards

EATON www.EatonCanada.ca/PRLCS

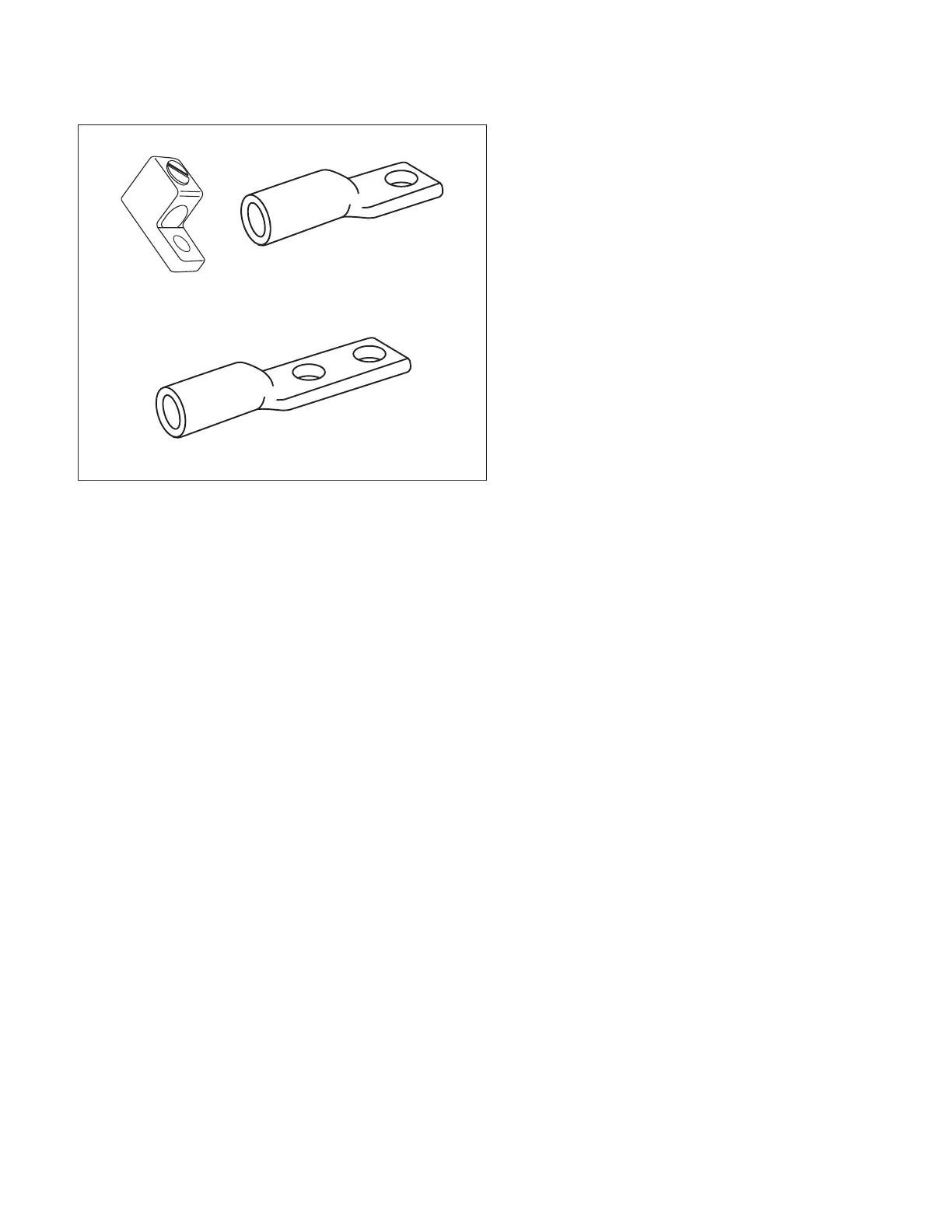

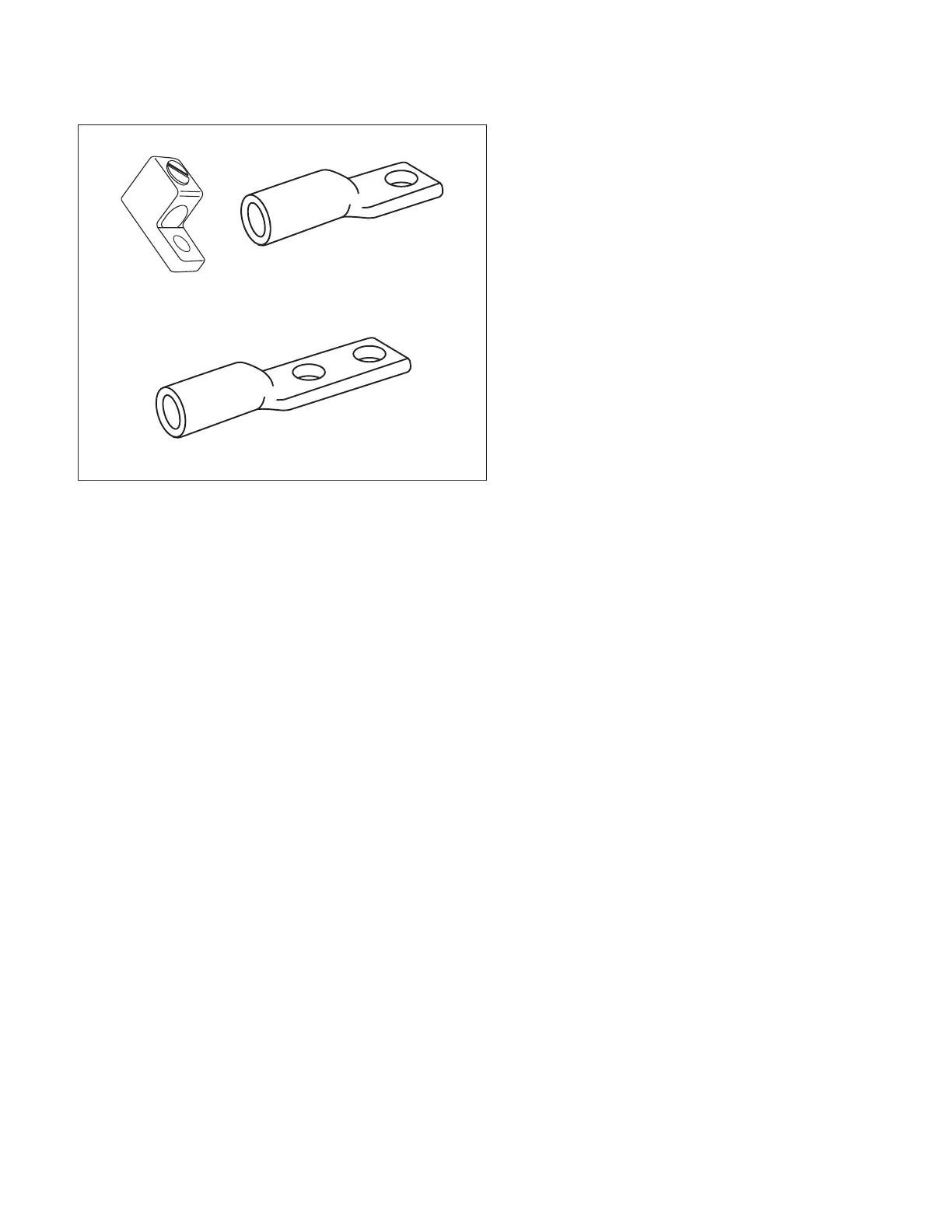

Mechanical set

Standard one-hole

Optional two-hole

Figure 15. Screw and compression lugs

Unless a switchboard specifically restricts entry to a single means

or area, cables may enter through the top, bottom, side or back of

the main incoming section. These restrictions are typically required

to conform to wire bending space requirements of the CEC. Consult

the manufacturer ’s drawings for conduit entry data.

Once the conductors are pulled inside the main section, the cables

should be formed in the space provided. Clearly identify and

segregate conductors by phase and neutral. Care should be taken

in forming insulated cables to ensure that no insulation is forced

permanently against the edges of any metal parts.

Using appropriate tools, the installer must strip the conductor

insulation sufficiently to fill the entire barrel of the connector with

bare, uninstalled conductor. Conductor must be stripped without

damage to the conductor strands. Bare strands should be of equal

length (flush) on the end cut.

Do not strip off more insulation than needed. Exposure of bare

conductor outside lug can compromise clearances.

The connector and conductor should be free of all foreign debris.

Never clip cable/wire strands in order to fit within connectors. If

cable/wire does not match the rating of the connector, contact the

manufacturer.

Mechanical set screw lugs are the most common. Use an

antioxidant compound, if required. Insert bare conductor into lug so

the bare conductor fills the full length of the lug body. Tighten lug,

then torque to levels indicated on the switchboard label.

If compression lugs are utilized and supplied with the switchboard,

the lugs will be mounted on the incoming lug pad. Remove lugs

from the pad. Use an antioxidant compound, if required. Use a

crimping tool approved for that specific lug manufacturer and lug

size. Follow instructions provided by the manufacturer of the crimp

tool.

Once the lug is affixed to the conductor, re-install the lug on the

lug pad utilizing the existing hardware. Torque hardware using

information provided on switchboard labeling. Refer to Appendix

Table 2 for torque values..

Loading...

Loading...