Do you have a question about the Eaton UltraShift PLUS and is the answer not in the manual?

Safety warnings and cautions for operating and servicing the transmission. Includes important precautions.

Essential steps for timing transmission gears to ensure proper mesh and function.

Routine checks and maintenance to ensure transmission longevity and reliability.

Crucial guidelines for safe and correct transmission assembly and disassembly.

General guidelines and specific precautions for assembling transmission components.

General guidelines and specific precautions for disassembling transmission components.

Procedure for removing the LAS/VAS auxiliary section while the transmission is in the chassis.

Detailed procedure for removing and disassembling the LAS/VAS auxiliary section.

Procedure for removing the LAS/VAS auxiliary section from the main case.

Procedure for assembling and installing the LAS/VAS auxiliary section.

Procedure for assembling the LAS/VAS auxiliary section onto the transmission.

Instructions for installing and timing the auxiliary counter shafts.

Procedure for shimming and installing auxiliary counter shafts for correct endplay.

Procedure for removing the VCS/VMS auxiliary section while the transmission is in the chassis.

Detailed procedure for removing and disassembling the VCS/VMS auxiliary section.

Procedure for disassembling the auxiliary mainshaft assembly.

Procedure for assembling and installing the VCS/VMS auxiliary section.

Procedure for assembling the VCS/VMS auxiliary section.

Instructions for assembling and timing auxiliary countershafts.

Procedure for removing and disassembling the MHP/MXP/VHP/VXP auxiliary section.

Procedure for removing the MHP/MXP/VHP/VXP auxiliary section.

Procedure for disassembling the MHP/MXP/VHP/VXP auxiliary section.

Procedure for disassembling the auxiliary mainshaft assembly.

Procedure for assembling and installing the MHP/MXP/VHP/VXP auxiliary section.

Procedure for assembling the auxiliary mainshaft assembly.

Instructions for installing MHP/MXP/VHP/VXP auxiliary countershafts.

Procedure for installing the range cylinder and piston.

Procedure for installing the splitter cylinder.

Procedure for shimming and installing auxiliary counter shafts for correct endplay.

Procedures for removing, installing, and servicing the input shaft.

Procedure for replacing the input shaft without full transmission disassembly.

Procedure for installing the input shaft assembly into the transmission.

Procedures for removing, installing, and servicing the clutch housing.

Step-by-step procedure for removing the clutch housing.

Step-by-step procedure for installing the clutch housing.

Procedure for removing the shift bar housing from the transmission.

Instructions for installing the cast iron shift bar housing.

Instructions for installing the aluminum shift bar housing.

Procedures for removing and installing the electronic clutch actuator.

Procedure for removing the electronic clutch actuator from the transmission.

Procedure for installing the electronic clutch actuator onto the transmission.

Procedures for removing and installing the TECU.

Procedure for removing the transmission electronic control unit.

Procedure for installing the transmission electronic control unit.

Procedures for removing and installing the X-Y shifter.

Procedure for removing the X-Y shifter from the transmission.

Procedure for installing the X-Y shifter onto the transmission.

Procedures for installing the oil pump and lubrication tubes.

Procedure for installing the oil pump into the transmission.

Procedure for installing the transmission lubrication tubes.

Procedure for timing and assembling gears within the main case.

Procedure for installing the counter shafts into the main case.

Procedure for installing the auxiliary section onto the main case.

Procedures for disassembling and assembling the VCS/VMS combination cylinder.

Procedure for disassembling the VCS/VMS combination cylinder.

Procedure for assembling the VCS/VMS combination cylinder.

Procedures for disassembling and assembling the LAS/VAS range cylinder.

Procedure for disassembling the MHP/MXP/VHP/VXP range cylinder.

Procedures for disassembling and assembling the shift bar housing.

Procedure for disassembling the main case main shaft without low force gearing.

Procedure for assembling the main case main shaft without low force gearing.

Procedure for disassembling the main case main shaft with low force gearing.

Procedure for assembling the main case main shaft with low force gearing.

Procedures for disassembling the main case and removing lubrication tubes.

Flowchart and steps for inspecting and identifying transmission oil leaks.

List of torque values for various fasteners and components.

List of torque values for various fasteners and components specific to LAS/VAS models.

Guidelines for transmission lubrication, including cautions, operating angles, and temperatures.

Recommends specific grease types and ratings for release bearing lubrication.

Procedures for calibrating the transmission's grade sensor.

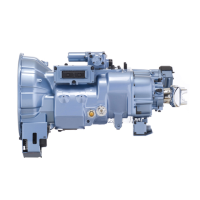

| Brand | Eaton |

|---|---|

| Model | UltraShift PLUS |

| Category | Microphone system |

| Language | English |

Loading...

Loading...