5

Section III – Principles of Operation

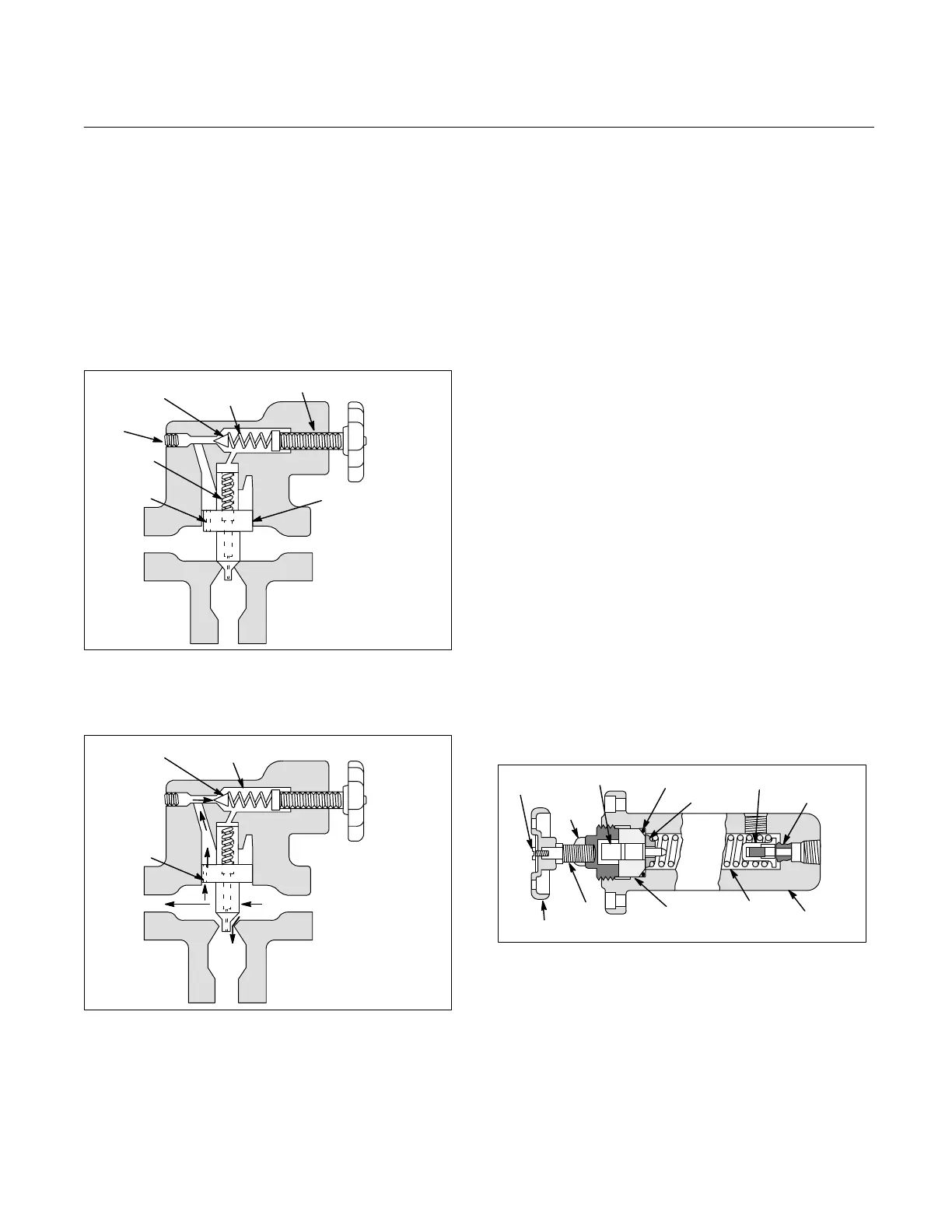

A. Pressure Relief

Figure 1 illustrates the basic valve operation. The valve pres-

sure setting is determined by the adjusting screw position

which varies the heavy spring compression. The balanced

piston is normally held against the seat by the light spring.

System pressure is present in chamber A and is connected

to chamber B through orifice C.

The closed position of the valve is shown in Figure 1A. With

system pressure less than the valve setting, the pilot poppet

is held against its seat by spring force. Pressures in cham-

bers A and B equalize through orifice C. Thus, the piston is

hydraulically in balance and held against its seat by the light

spring.

Figure 1A.

Poppet

Balanced

Piston

A

Vent

Connection

Light

Spring

Orifice

Heavy

Spring

Adj. Screw

(System Pressure)

To

Tank

A

C

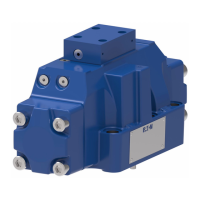

In Figure 1B the valve is shown throttling fluid to the tank

port. This occurs when system pressure exceeds the heavy

spring setting and forces the poppet away from its seat.

Figure 1B.

Poppet

A

Orifice

To

Tank

B

C

D

B

Fluid then flows through orifice C and chamber B, past the

poppet into chamber D, and down through the drain hole in

the center of the piston to the tank port.

The pressure in chamber B is limited by the setting of the heavy

spring. When pressure in chamber A exceeds chamber B

sufficiently, pressure unbalance overcomes the force of

the light spring and lifts the piston. Excess fluid then flows past

the bottom of the piston to tank.

When the system pressure drops below the valve setting,the

poppet reseats. Control flow through orifice C stops and

pressures in chambers A and B are again effectively

equalized.

The light spring then forces the piston toward the seat while

orifice C continues to equalize pressure between chambers

A and B. When the balance piston is closed against its seat,

all flow through orifice C stops.

B. Venting

The ”High-Vent” option (”V” in the model code) is used when

it is necessary to maintain pilot pressure for other valves in

the system. This option provides a faster valve de-venting

(closing) action. Higher pressure (approximately 80 PSIG) is

maintained when the valve is vented because a heavier

piston spring is used.

Relief valves can be vented to unload pump delivery to tank in

the following manner:

Connect a shut-off valve to the vent port of the main relief valve.

Chamber ’B’ above the balanced piston can be opened to tank

(see Figure 1B). This removes pressure at the top of the

balanced piston. Pressure in chamber ’A’ overcomes the light

spring, unseats the balanced piston, and diverts all pump

delivery to tank.

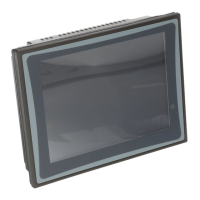

A solenoid controlled directional valve (C*5) may be used

to vent flow to tank. This directional valve is mounted on top

of a standard relief valve to form a single package. See

Figure 6.

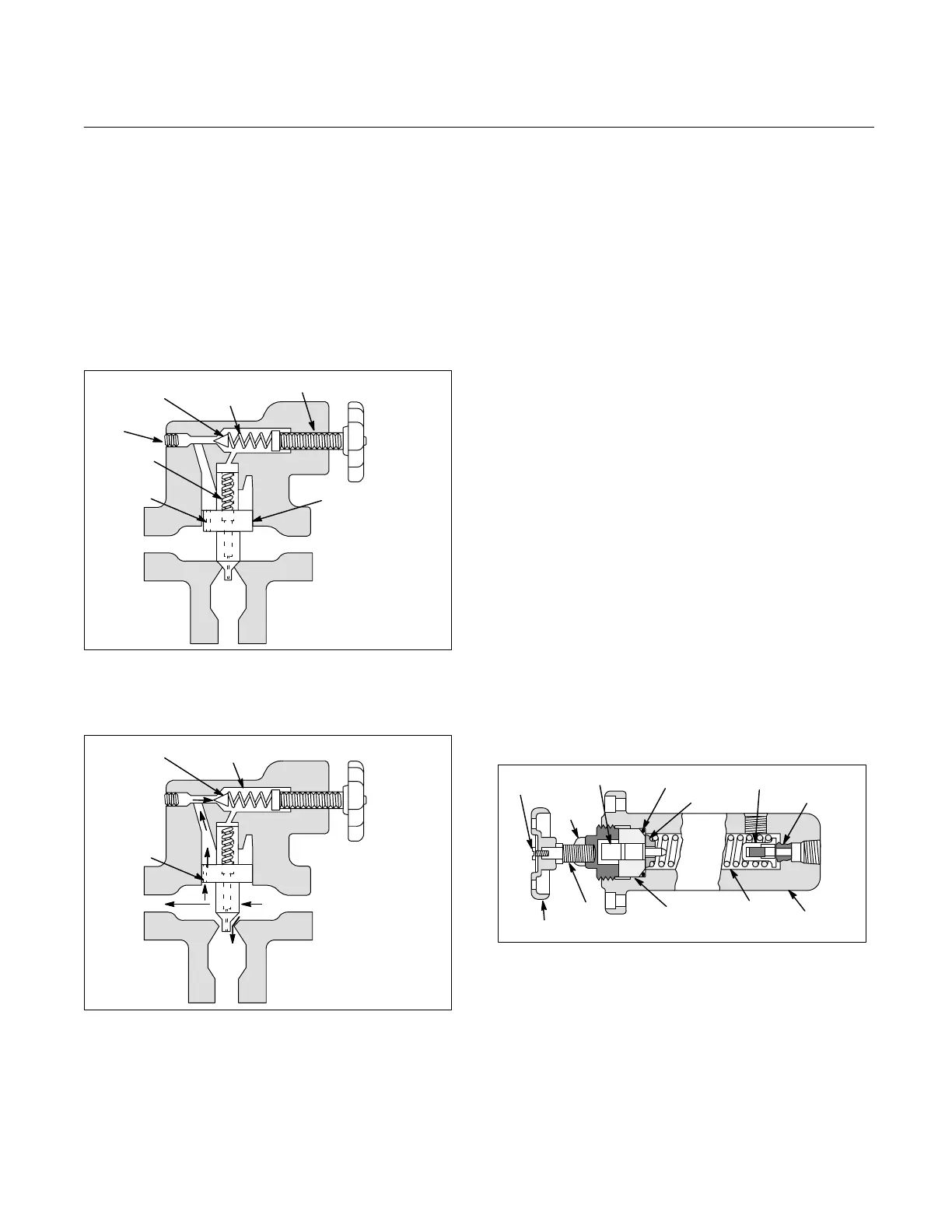

C. Remote Control

The main relief valve may be adjusted from a remote location

by using another adjustable valve similar in function to the

main relief valve pilot stage (see Figure 2.) Flow past the

poppet of the remote control valve is directed to tank. The

following rules should be maintained for optimum results:

Figure 2.

Poppet

Plunger

Lock

Nut

Seat

O-ring

Guide

Body

Spring

Retainer

Adj.

Screw

Knob

Screw

1. Keep hydraulic lines (tubing) as short as possible.

2. Set main relief valve 200-300 PSIG above maximum

operating pressure. DO NOT exceed the valve pressure rating.

3. Set remote control valve to maximum operating

pressure.

4. Check system for stability characteristics. If the system

is unstable, reduce the line length and/or proceed to step 5.

5. Install an orifice in the vent opening of the main relief

valve cover and in the pressure port of the remote control valve.

DO NOT go below 0.040 inch diameter or a malfunction could

result. Orifices should be as large as possible to prevent exces-

sive pressure drop and still maintain noise free operation.

Loading...

Loading...