Do you have a question about the ebm-papst ACi 4400 HHU-511 and is the answer not in the manual?

Explains the meaning of DANGER, WARNING, CAUTION, NOTE risk ratings.

Defines who is allowed to install and operate the product.

General rules for working with the product.

Covers electrical voltage, current, and related dangers.

Discusses safety devices, protective equipment, and EMC.

Addresses risks associated with moving parts like impellers.

Covers risks related to hot surfaces and fire spreading.

Lists prohibited uses that are dangerous.

Mentions requirements for assessing heating, protection, etc.

Details airflow, frequency, voltage, consumption, speed, flow, mass, protection class, torque, screw size.

Specifies permitted ambient temperature for transport, storage, and operation.

Information on mechanical vibration and shock data.

Instructions for handling and mounting the product mechanically.

Covers electrical connection, voltage safety, and regulations.

Notes EMC effects on system integration.

States speed control via supply voltage or PWM is not permitted.

Details voltage checks, nameplate data, and cable specifications.

Provides wiring diagram and states fans are not to be earthed.

Lists common faults, possible causes, and remedial actions.

Outlines periodic checks for safety and product integrity.

Confirms the product bears CE and EAC marks.

Details how the document aligns with various EU directives.

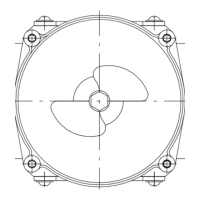

This document outlines the operating procedures and safety guidelines for the ebm-papst ACI 4400 HHU-511, a built-in fan designed for air conveyance. It serves as an integral part of the product, intended to accompany it through resale or changes in ownership, and provides essential information regarding potential risks and their avoidance.

The ACI 4400 HHU-511 is engineered as a built-in device primarily for conveying air. Its design focuses on integration into larger systems, where it performs its air movement function according to specified technical data. The product is designed to operate in open and unsheltered areas, with direct exposure to water and saline ambient conditions being permissible, provided normal operation is not hindered. It is important to note that the motor automatically restarts after a mains failure or when a blockage is cleared, emphasizing the need for caution around moving parts.

The product is intended for specific applications and must be used in accordance with the provided technical data and operating manual. Key usage features include:

Regular maintenance and safety checks are essential to ensure the continued safe and efficient operation of the ACI 4400 HHU-511.

| Size | 119 x 119 x 38 mm |

|---|---|

| Voltage | 230 VAC |

| Airflow | 160.0 m³/h |

| Noise level | 43 dB(A) |

| Housing material | Aluminum |

| Protection class | IP54 |

Loading...

Loading...