Do you have a question about the ebm-papst A4E450-AN05-01 and is the answer not in the manual?

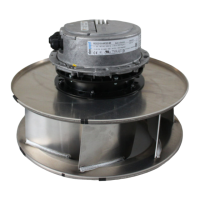

This document outlines the operating instructions for the A4E450-AN05-01 device, a built-in component designed for conveying air.

The A4E450-AN05-01 is a single-phase external rotor motor with an impeller, primarily intended for air conveyance within an ambient air pressure range of 800 mbar to 1050 mbar. Its design allows for operation within a specified ambient temperature range, ensuring optimal performance and service life. The device is equipped with a thermal overload protector (TOP) with basic insulation for motor protection and operates with a counterclockwise rotation when viewed toward the rotor. It is designed to be a built-in component, and its proper functioning relies on correct installation and adherence to safety regulations. The device is not intended for medical equipment with life-sustaining functions, conveying solids or abrasive particles, or operation in explosive atmospheres.

Motor: M4E094-FA Phase: 1~ Nominal Voltage / VAC: 230 Frequency / Hz: 50 Power Consumption / W: 450 Current Draw / A: 2.1 Speed (rpm) / min-1: 1300 Capacitor / µF: 8 Capacitor Voltage / VDB: 400 Max. Back Pressure / Pa: 120 Min. Ambient Temperature / °C: -40 Max. Ambient Temperature / °C: 60 Weight: 6 kg Size: 450 mm Rotor Surface: Painted black Terminal Box Material: PP plastic Blade Material: Press-fitted sheet steel blank, sprayed with PP plastic Number of Blades: 5 Airflow Direction: V Direction of Rotation: Counterclockwise, viewed toward rotor Degree of Protection: IP54 Insulation Class: "F" Moisture (F) / Environmental (H) Protection Class: H2 Motor Bearing: Ball bearing Touch Current (according to IEC 60990): <= 3.5 mA Electrical Hookup: Terminal box Motor Protection: Thermal overload protector (TOP) with basic insulation Protection Class: I (with customer connection of protective earth) Motor Capacitor according to EN 60252-1 in Safety Protection Class: S0 Overall Efficiency (nes / %): 31.5 (Actual), 31.4 (Req. 2015) Efficiency Category: Static Efficiency Grade N: 40.1 (Actual), 40 (Req. 2015) Specific Ratio: 1.00

The device is designed for conveying air and must be operated with all protective devices in place. It requires a stable power supply matching its nominal voltage and frequency. When connecting, it is crucial to ensure proper grounding and secure electrical connections. The cable routing should prevent water ingress into the terminal box, with recommendations for U-shaped loops or drip edges. The device is a built-in component and does not have a disconnecting switch; therefore, it must be connected to circuits that can be switched off with an all-pole disconnection switch. For variable frequency drive operation, sinusoidal filters are required to protect the motor from high-voltage transients and harmful bearing currents. The device's rotating parts are designed for a maximum of one million load cycles, and any special questions regarding cyclic speed loads should be directed to ebm-papst.

Regular maintenance is essential for ensuring a long service life. This includes checking the fan for proper operation and soiling, with the frequency of checks adapted to the degree of soiling. Cleaning should only be performed when the fan is not in motion, with the power supply interrupted and secured against renewed switch-on. Dry cleaning, such as using compressed air, is the preferred method. Aggressive cleaning agents, water jets, high-pressure cleaners, acids, alkalis, solvents, or pointed/sharp-edged objects should not be used. All cleaning agents must be completely removed.

A safety inspection should be performed at least every 6 months, including:

If the device is not operated for a lengthy period in a dry environment, it should be started up and operated at full speed for one hour at least every four months. In a damp environment (e.g., outdoors), this should be done for at least two hours once a month to move the bearings and evaporate any condensate. In the event of malfunctions, repairs should not be attempted by the user; instead, the device should be sent to ebm-papst for repair or replacement. Disassembly for disposal must be performed by qualified personnel, with heavy components secured to prevent injury. The product's components (steel, copper, aluminum, plastic, insulating materials, cables, electronic scrap, ferrite magnets) should be separated for recycling according to applicable country-specific legal regulations.

Loading...

Loading...