Do you have a question about the ebm-papst S4E350-AG06-28 and is the answer not in the manual?

Explains hazard level symbols (DANGER, WARNING, CAUTION, NOTE) used in the document.

Specifies that only qualified, trained, and authorized personnel should handle the device.

Outlines general safety guidelines, workplace tidiness, and modifications.

Warns about electrical hazards and checking connections.

Details requirements for protective devices to prevent serious injury during operation.

Covers hazards related to rotating parts and entanglement risks.

Addresses noise levels and the need for hearing protection.

Warns about hot motor housing and the risk of burns.

Provides guidance on safely transporting the device in its original packaging.

Recommends storage conditions for optimal operation and service life.

Lists prohibited and potentially hazardous operating conditions for the device.

Provides a detailed technical drawing with dimensions and component labels.

Presents key technical specifications of the motor in a tabular format.

Details physical characteristics like weight, materials, and blade specifications.

Specifies screw strength class and refers to further mounting data.

Outlines permitted ambient temperatures for transport and storage.

Provides instructions and warnings regarding the physical installation of the fan.

Covers safety precautions and requirements for wiring the device.

Details the process of preparing and connecting wires within the terminal box.

Shows the wiring schematic for connecting the device's terminals.

Explains how to create an additional cable gland opening in the terminal box.

Details steps to ensure secure and proper electrical connections before operation.

Lists checks and warnings before powering on the installed device.

Provides instructions on how to safely disconnect power to the device.

Provides guidelines on how to clean the device safely.

Outlines a schedule and methods for visually inspecting critical components.

Offers recommendations for environmentally sound disposal of the product and its components.

This document outlines the operating instructions for the S4E350-AG06-28 device, a built-in fan designed for conveying air. The manual emphasizes safety regulations, technical specifications, proper installation, and maintenance procedures to ensure safe and efficient operation.

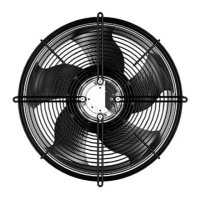

The S4E350-AG06-28 is an axial fan, specifically designed as a built-in component for air conveyance. Its primary function is to move air within a specified range of ambient air pressure (800 mbar to 1050 mbar) and within permitted ambient temperature ranges. The fan operates with a single-phase motor, and its design incorporates protective features to ensure safe operation. The device is intended for use with all protective devices in place and in accordance with the provided operating instructions. It is crucial to avoid improper use, such as operating the device in an unbalanced state, with severe vibration, or in explosive atmospheres, as this can lead to hazards or damage. The fan's rotor and impeller are energized in the event of a fault, and the motor can restart automatically after a power failure, necessitating caution during maintenance.

The device, identified as Motor M4E068-EC, has the following key technical specifications:

The fan's rotating parts are designed for a maximum of one million load cycles. The surfaces conform to industrial standards, though color changes due to UV exposure are not covered by warranty.

The device is designed for specific installation and operational conditions.

Regular maintenance and safety inspections are crucial for the device's longevity and safe operation.

Loading...

Loading...