Do you have a question about the ebm-papst A4E450-BA09-01 and is the answer not in the manual?

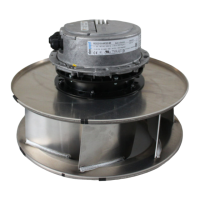

This document describes the A4E450-BA09-01 device, an axial fan designed as a built-in component for conveying air. It is intended for industrial applications where air movement is required, and its design emphasizes safety, reliability, and ease of maintenance within its specified operating parameters.

The A4E450-BA09-01 is primarily designed to convey air. It operates by rotating an impeller to generate airflow, which can be used for various ventilation, cooling, or air circulation tasks within a system or machine. The device is a single-phase motor, indicating its suitability for common electrical power supplies. It incorporates a thermal overload protector (TOP) within its winding to safeguard the motor against overheating, ensuring operational safety and extending its service life. The motor is equipped with ball bearings, which contribute to its smooth operation and durability. The design includes a terminal box for electrical connections, ensuring a secure and protected interface for power supply and control signals. The fan's airflow direction is counterclockwise when viewed toward the rotor, a critical detail for proper integration into an air-moving system.

The device is designed for use in environments with ambient air pressure between 800 mbar and 1050 mbar and within a specified ambient temperature range. It is crucial to operate the device with all protective devices in place and to follow the provided operating instructions to ensure safe and effective use. The fan is a built-in component, meaning it is integrated into a larger system or machine, and the owner is responsible for ensuring adequate safeguarding, such as fixed protective devices and guard grills.

Proper mechanical connection is vital for the device's performance and longevity. The fan should be carefully removed from its packaging, handled by the blades near the hub, and set down on a soft surface to prevent damage to the impeller. During installation, it's essential to ensure the impeller moves freely and that its blades are not deformed or bent. The device must be securely positioned and attached to the substructure without strain on its fastening points. Vibration isolation is recommended, especially when connecting to air ducts, to prevent bearing damage and shorten service life.

Electrical connection requires careful attention to safety. A protective earth connection must always be established first. The device should only be connected to circuits that can be switched off with an all-pole disconnection switch. Cables used for connection must meet specified installation regulations for voltage, current, and insulation material, and they should be routed to avoid contact with rotating parts. The terminal box is designed for secure connections, and cable glands must be properly sealed to prevent moisture ingress, which can damage the device. For fans installed lying flat, cables should be routed in a U-shaped loop, and for upright installations, cable glands should be at the bottom with cables routed downward.

The device is equipped with a motor capacitor, which has a safety protection class P0/S0 according to EN 60252-1. This detail is important for users when integrating the fan into their end product, ensuring compliance with applicable regulations. While voltage control is possible, users should be aware of potential current overshoots, noise, and vibration, which could lead to bearing damage. If variable frequency drives are used, sinusoidal filters are recommended to protect the motor from high-voltage transients and harmful bearing currents.

Regular maintenance is crucial for ensuring a long service life and proper operation of the A4E450-BA09-01. This includes periodic checks for soiling, visible external damage, and the functionality of protective devices. The frequency of these checks should be adjusted based on the degree of soiling in the operating environment.

Cleaning the device is a primary maintenance task. It should only be cleaned when not in motion, with the power supply interrupted and secured against renewed switch-on. Dry cleaning, such as using compressed air, is the preferred method. Aggressive cleaning agents, water jets, high-pressure cleaners, acids, alkalis, solvents, or pointed/sharp-edged objects should not be used, as they can damage the device. All cleaning agents must be completely removed after cleaning. Dirt deposits on the motor housing can cause overheating, and soiling of the impeller can lead to vibrations, shortening the fan's service life and potentially destroying it. If vibrations persist after cleaning, the fan may need rebalancing.

A safety inspection should be performed at least every six months. This inspection includes checking the contact protection cover for intactness or damage, inspecting the device for damage to blades and housing, and verifying the fastening of cables and the protective earth terminal. The insulation of cables should be checked for damage, and cable glands should be inspected for tightness and retightened or replaced if necessary. Condensation drainage holes should be checked for clogging and cleared if needed. Welds should be inspected for crack formation, and any abnormal bearing noise should be investigated.

The fan is equipped with maintenance-free ball bearings, lubricated for a service life of 40,000 hours. If bearing replacement becomes necessary after this period, ebm-papst should be contacted for support. Maintenance intervals should be adapted to the actual level of dust exposure in the operating environment.

In cases of malfunction, users should not attempt repairs themselves but should send the device to ebm-papst for repair or replacement. Before any work on the device, it is imperative to disconnect the voltage at all poles and wait five minutes for capacitors to discharge to prevent electric shock. If the device is not operated for an extended period, it should be started up and run at full speed for at least one hour every four months in a dry environment, or for at least two hours once a month in a damp environment, to move the bearings and evaporate any condensate.

Disassembly of the product for disposal should be performed or supervised by qualified personnel. Components, primarily steel, copper, aluminum, and plastic, should be separated for recycling according to applicable country-specific legal regulations. Ferrite magnets, if present, can be disposed of with normal iron and steel.

| Manufacturer | ebm-papst |

|---|---|

| Model Number | A4E450-BA09-01 |

| Type | Axial Fan |

| Voltage | 230 V |

| Frequency | 50/60 Hz |

| Motor Type | External Rotor Motor |

| Protection Class | IP54 |

| Category | Fan |

| Dimensions | 450 mm |

| Impeller Material | Plastic |

Loading...

Loading...