20 9 INCH CHIPPER

Section

5 SERVICE & MAINTENANCE

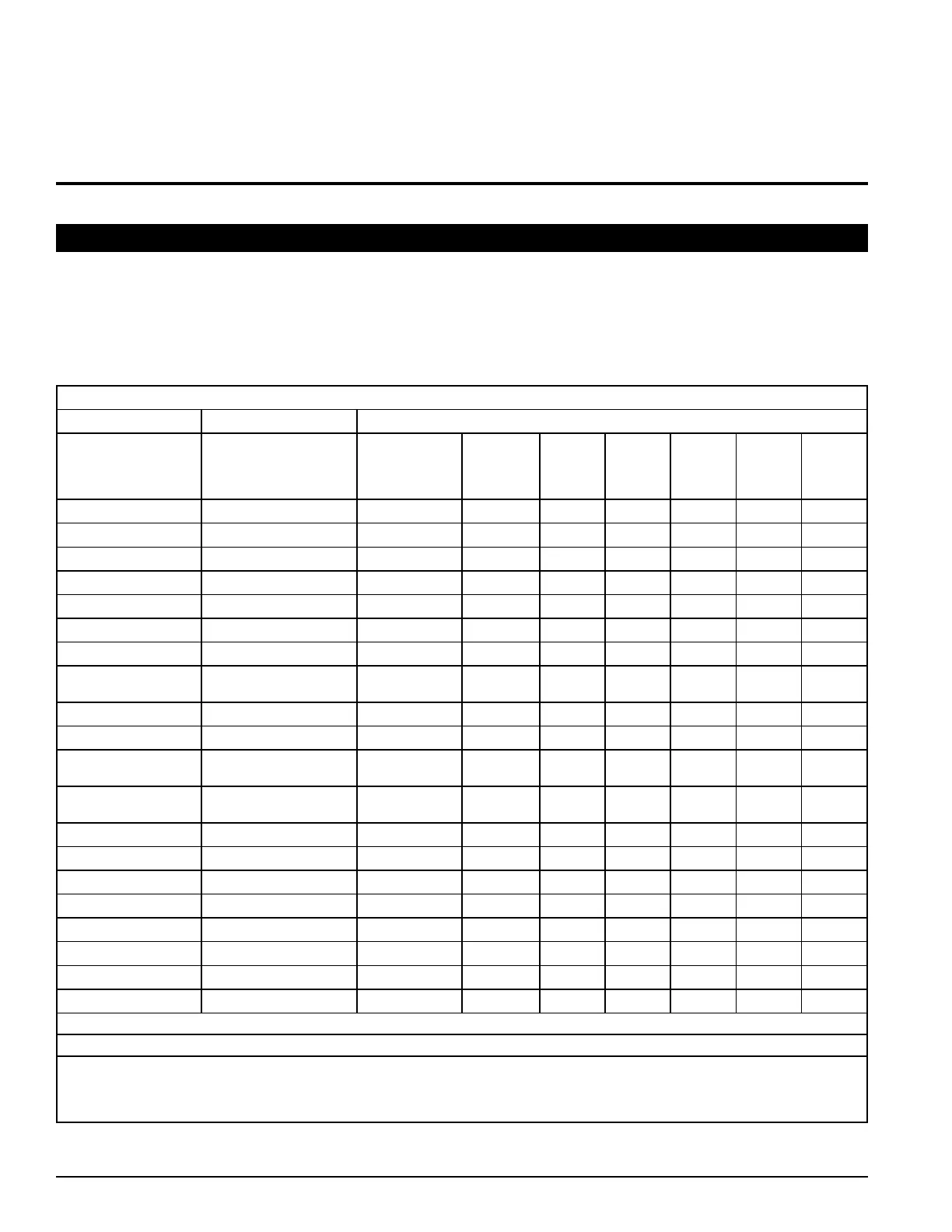

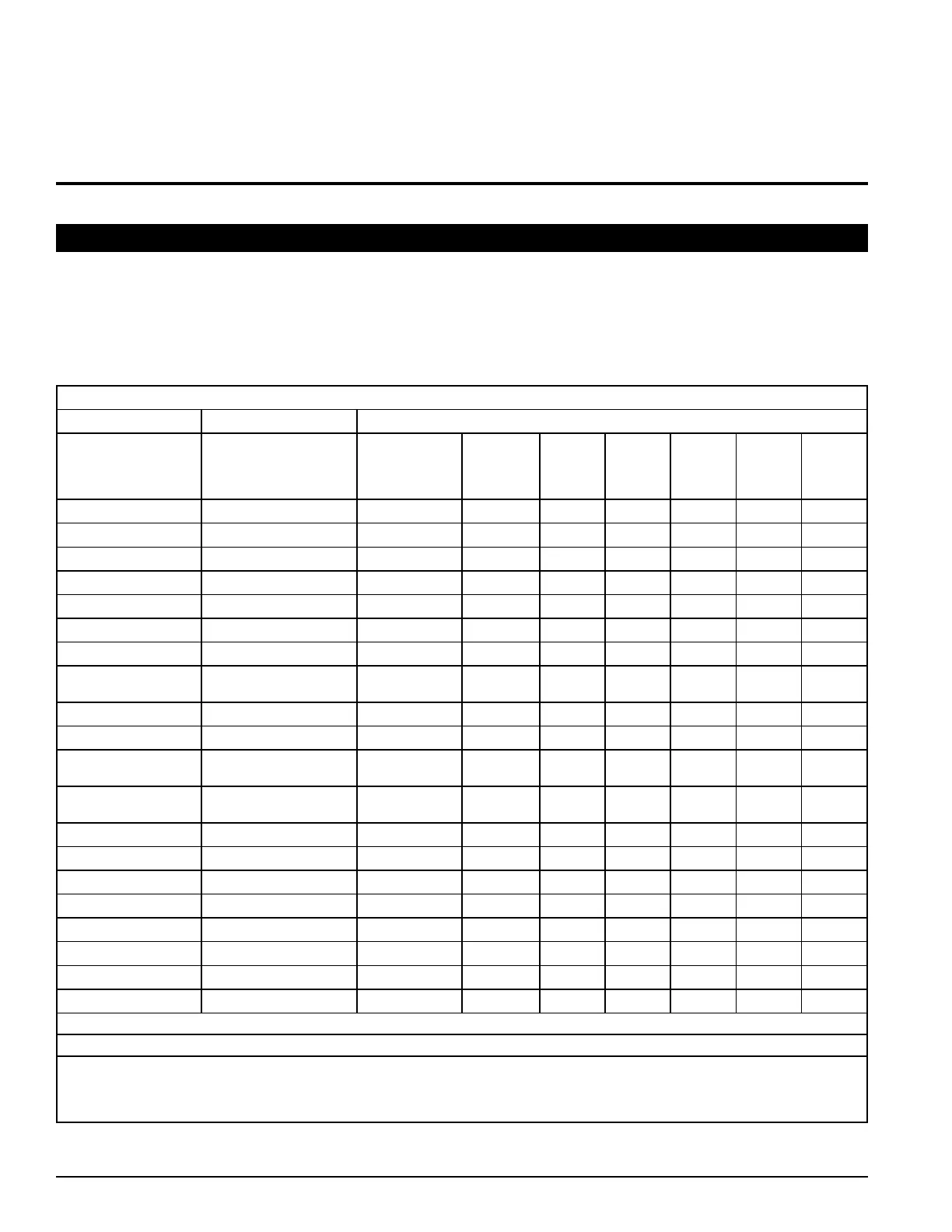

The items listed in this service and maintenance schedule are to be checked, and if necessary, corrective action taken.

This schedule is designed for units operating under normal conditions. If the unit is operating in adverse or severe

conditions, it may be necessary for the items to be checked and serviced more frequently.

SEE ENGINE OWNER’S MANUAL FOR FURTHER ENGINE MAINTENANCE AND TROUBLESHOOTING

INFORMATION.

SERVICE AND MAINTENANCE SCHEDULE

FREQUENCY

COMPONENT

MAINTENANCE

REQUIRED

REFER TO

ENGINE

OPERATOR’S

MANUAL

BEFORE

EACH

USE

EVERY

8

HOURS

EVERY

25

HOURS

EVERY

50

HOURS

EVERY

200

HOURS

EVERY

YEAR

Air cleaner Check and clean (1)

●

Air intake Clean (1)

●

Engine oil Change (1)

●

Fuel filter Replace

●

Hydraulic oil Check/fill

●

Engine oil Check/fill

●

Fuel tank Check/fill

●

All internal and external

nuts and bolts

Check tightness

●

Tire pressure Check

●

Battery connections Check

●

Chipper anvil

Check clearance and re-

torque to 75 ft-lbs. (2)

●

Chipper blades

Check sharpness and re-

torque to 120 ft-lbs. (2)

●

Entire machine Clean

●

Drive belt Check

●

Hydraulic drive belt Check

●

Belt tension Check

●

Belt/pulley alignment Check

●

Grease zerks Lube

●

Hydraulic oil filter Replace

●

Wheel bearings Check and repack

●

(1) Perform more frequently under extremely dusty conditions.

(2) Perform more frequently when chipping dry or dirty wood.

As the Limited Warranty states, failure by the Owner to perform normal maintenance will void the machine’s warranty. The aggressive,

high-speed nature of chipping REQUIRES THE OWNER TO PERFORM THE ABOVE LISTED NORMAL MAINTENANCE. Special

consideration to maintain and re-torque the CHIPPER ANVIL, CHIPPER BLADES, and ALL INTERNAL AND EXTERNAL NUTS AND

BOLTS is the sole responsibility of the Owner. Failure by the Owner to do so shall be cause for denial of warranty.

5.1 MAINTENANCE SCHEDULE

Loading...

Loading...