POWER PRUNER

TM

OPERATOR'S MANUAL

21

Your ECHO Power Pruner

TM

is designed to provide many hours of trouble free service. Regular scheduled maintenance

ZLOOKHOS\RXUSUXQHUDFKLHYHWKDWJRDO,I\RXDUHXQVXUHRUDUHQRWHTXLSSHGZLWKWKHQHFHVVDU\WRROV\RXPD\ZDQWWR

WDNH\RXUXQLWWRDQ(&+26HUYLFH'HDOHUIRUPDLQWHQDQFH7RKHOS\RXGHFLGHZKHWKHU\RXZDQWWR'2,7<285-

6(/)RUKDYHWKH(&+2'HDOHUGRLWHDFKPDLQWHQDQFHWDVNKDVEHHQJUDGHG,IWKHWDVNLVQRWOLVWHGVHH\RXU(&+2

Service Dealer for repairs.

SKILL LEVELS

NOTE

$OOPDLQWHQDQFHWDVNVPXVWEHSURSHUO\SHUIRUPHGRWKHUZLVHXQLWGDPDJHRUSHUVRQDOLQMXU\PD\RFFXU

Level 1 = Easy to do. Common tools may be required.

Level 2 0RGHUDWHGLI¿FXOW\6RPHVSHFLDOL]HGWRROVPD\EHUHTXLUHG

MAINTENANCE

WARNING

0RYLQJSDUWVFDQDPSXWDWH¿QJHUVRUFDXVHVHYHUHLQMXULHV.HHSKDQGVFORWKLQJDQGORRVHREMHFWVDZD\IURPDOO

RSHQLQJV$OZD\VVWRSHQJLQHGLVFRQQHFWVSDUNSOXJDQGPDNHVXUHDOOPRYLQJSDUWVKDYHFRPHWRDFRPSOHWH

VWRSEHIRUHUHPRYLQJREVWUXFWLRQVFOHDULQJGHEULVRUVHUYLFLQJXQLW$OORZXQLWWRFRROEHIRUHSHUIRUPLQJVHUYLFH

Wear gloves to protect hands from sharp edges and hot surfaces.

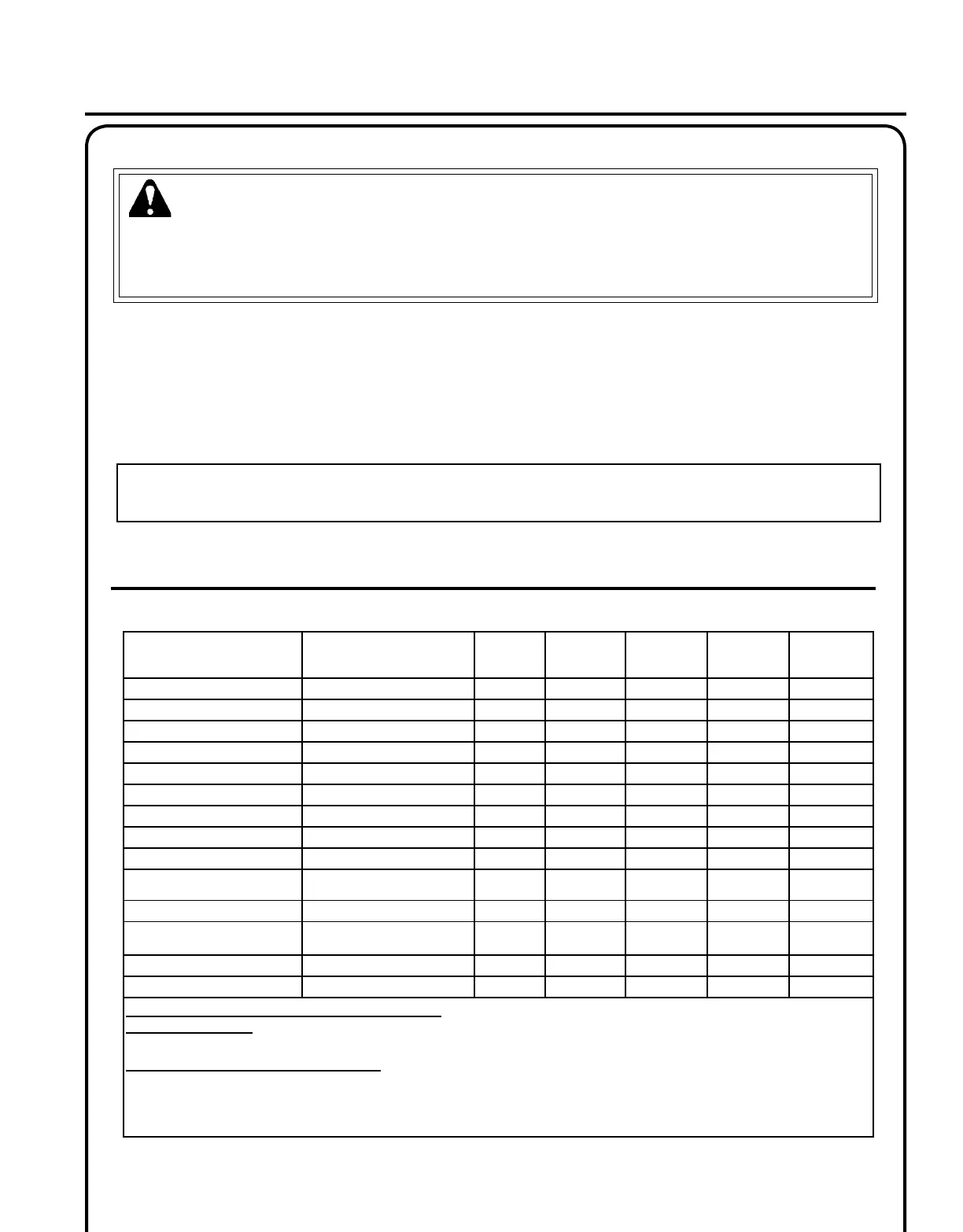

COMPONENT / SYSTEM

MAINTENANCE

PROCEDURE

REQ'D

SKILL

LEVEL

DAILY OR

BEFORE

USE

EVERY

REFUEL

3 MONTHS

OR 90

HOURS

YEARLY 600

HOURS

Air Filter Inspect/Clean 1

I / C * R *

Choke Shutter Inspect/Clean 1

I / C

Fuel Filter Inspect/Replace 1

I * I / R *

Fuel Cap Gasket Inspect/Replace 1

I * R *

Fuel System Inspect/Replace 1

I (2) * I (2) *

Spark Plug Inspect/Clean/Replace 1

I/C/R *

Cooling System Inspect/Clean 2

I / C

Muffler Spark Arrestor Inspect/Clean/Replace 2

I/C/R *

Cylinder Exhaust Port Inspect/Clean/Decarbon 2

I / C

Drive Shaft (Flex Cable

Models

Inspect/Grease

2

I (1)

Guide Bar / Sprocket Nose Inspect/Clean/Lubricate 2

I / C * I

Saw Chain

Inspect/Sharpen/

Replace/Tension

2

I * I *

Recoil Starter Rope Inspect/Clean 1

I / C *

Screws/Nuts/Bolts Inspect/Tighten/Replace 1

I *

(2) Low evaporative fuel tanks DO NOT require regular maintenance to maintain emission integrity.

* All recommendations to replace are based on the finding of damage or wear during inspection.

MAINTENANCE PROCEDURE LETTER CODES:

I = INSPECT, R = REPLACE, C = CLEAN

IMPORTANT NOTE

- Time intervals shown are maximum. Actual use and your experience will determine the

frequency of required maintenance.

MAINTENANCE PROCEDURE NOTES:

(1) Apply POWER BLENDX

TM

lubricant every 25 hours of use.

MAINTENANCE INTERVALS

Loading...

Loading...