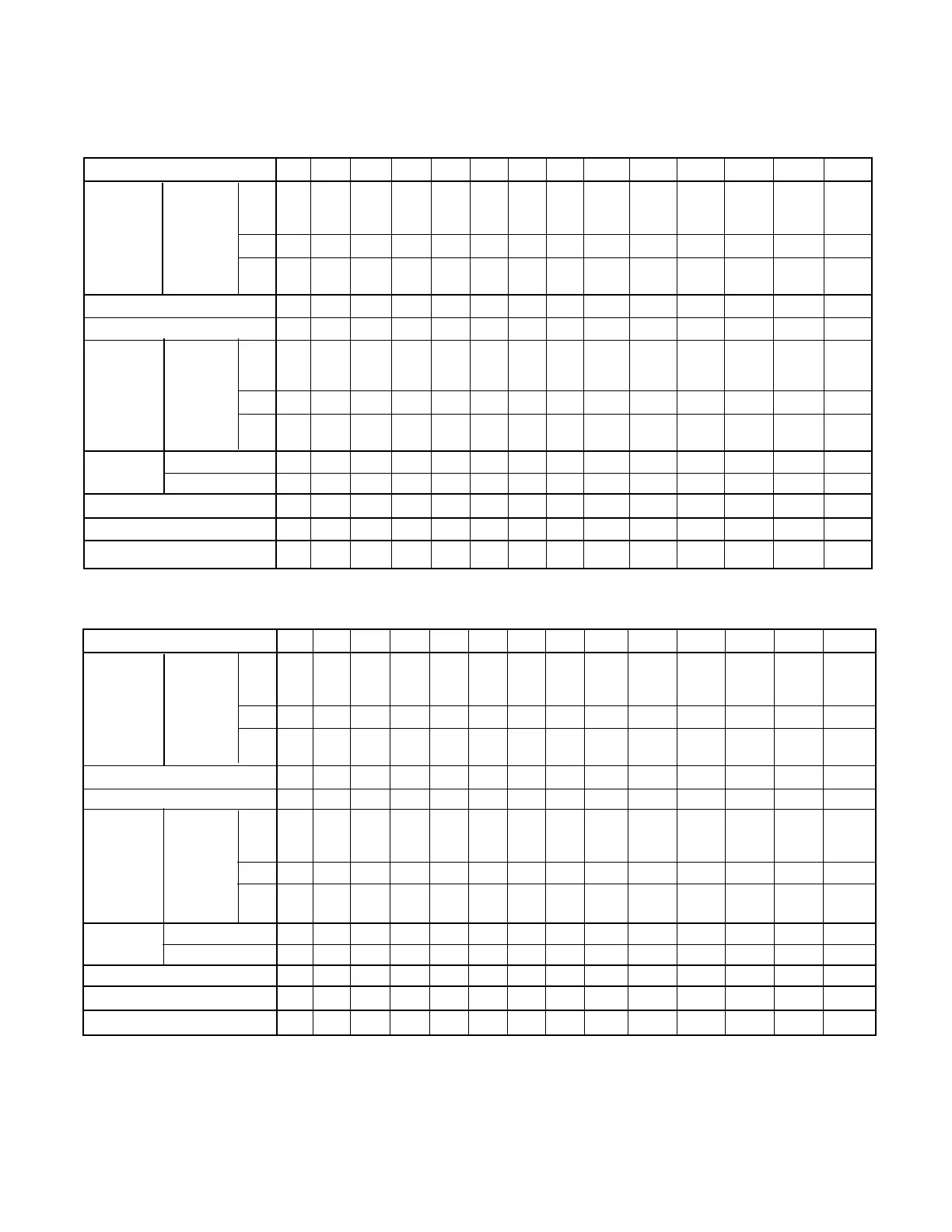

3

Burner Size 50 100 150 200 300 400 500 600 750 1000 1250 1500 2000 2500

-12.5 205 410 616 850 1076 1369 1612 2052 2726 3664 4279 5188 6800 8090

-7.5 191 366 557 733 1002 1345 1612 1934 2521 3400 4045 4895 6448 7800

-2.5 161 322 484 645 924 1231 1521 1817 2315 3107 3781 4572 6067 7474

0.0 147 293 440 586 879 1172 1466 1759 2198 2931 3664 4397 5862 7328

+2.5 132 264 396 528 835 1112 1407 1685 2081 2755 3517 4221 5657 7152

+5.0 117 234 352 469 786 1049 1348 1612 1964 2579 3371 4015 5452 6990

11.7 7.3 8.8 8.8 19.1 16.1 19.1 19.1 22.0 29.3 36.6 44.0 58.6 73.3

Turndown 12:1 40:1 50:1 67:1 46:1 73:1 77:1 92:1 100:1 100:1 100:1 100:1 100:1 100:1

-12.5 11.2 13.7 12.2 15.2 18.2 18.7 11.2 18.4 20.2 24.4 29.9 22.7 21.7 30.6

-7.5 9.7 11.0 10.0 11.2 15.9 17.9 11.2 16.2 17.4 21.2 26.7 20.2 19.7 28.4

-2.5 7.0 8.5 7.5 8.7 13.5 15.2 10.0 14.4 14.7 17.2 23.4 17.4 17.4 26.2

0.0 5.7 7.0 6.2 7.2 12.2 13.7 9.2 13.5 13.2 15.7 21.9 16.2 16.2 25.2

+2.5 4.7 5.7 5.0 5.7 11.0 12.5 8.5 12.5 11.7 14.0 20.2 14.9 15.2 23.9

+5.0 3.7 4.5 4.0 4.7 9.7 11.0 7.7 11.2 10.5 12.2 18.4 13.5 14.0 22.9

Minimum mbar 17 20 27 40 30 42 35 50 30 35 50 55 75 95

Maximum mbar

4

69 69 69 69 138 138 138 138 138 138 138 138 138 138

15 15 15 15 15 15 15 15 15 15 15 15 15 15

0.61 0.76 0.81 0.91 1.37 1.37 1.52 1.68 2.44 3.15 3.66 3.66 3.81 4.32

1/3 1/2 3/4 3/4 1-1/2 2 3 5 5 7-1/2 10 15 20 30

English Units

1

With neutral chamber. Will be slightly higher with negative chamber pressure.

2

Measured between tap“B” and the combustion chamber as shown on page 11.

3

At the inlet to the proportionator.

4

Under certain conditions, up to 5 psig (345 mbars) is allowable on RM 300 and larger burners; contact the factory for details.

5

At the inlet to the pilot cock.

6

High fire flame length measured from the end of the firing tube, firing parallel to air flow with neutral chamber pressure. When firing

perpendicular to air flow, flame length will be shorter. Contact your local Eclipse representative for details.

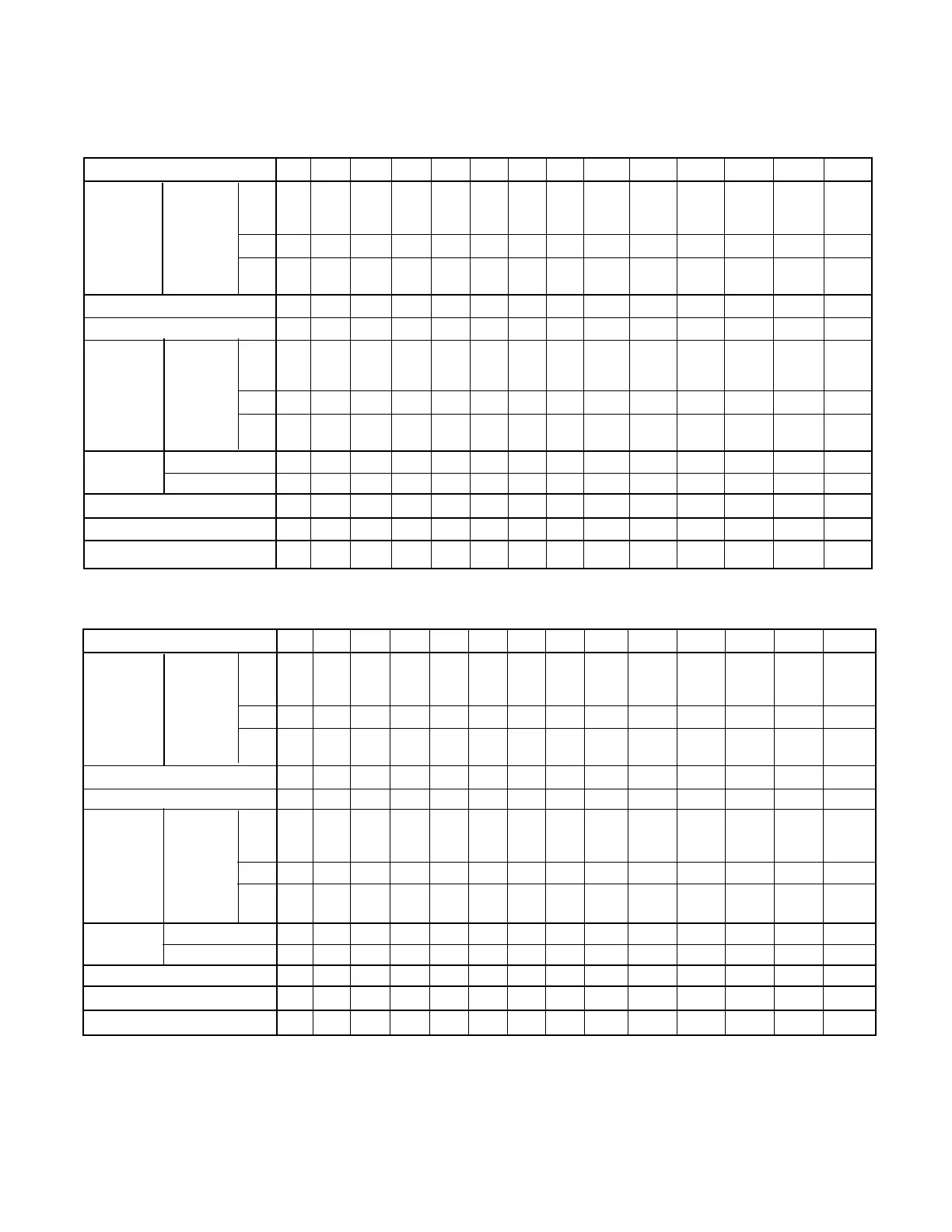

Burner Size 50 100 150 200 300 400 500 600 750 1000 1250 1500 2000 2500

-5.0 0.70 1.40 2.10 2.90 3.67 4.67 5.50 7.00 9.30 12.50 14.60 17.70 23.20 27.60

-3.0 0.65 1.25 1.90 2.50 3.42 4.59 5.50 6.60 8.60 11.60 13.80 16.70 22.00 26.60

-1.0 0.55 1.10 1.65 2.20 3.15 4.20 5.19 6.20 7.90 10.50 12.90 15.60 20.70 25.50

0.0 0.50 1.00 1.5 2.00 3.00 4.00 5.00 6.00 7.50 10.00 12.50 15.00 20.00 25.00

+1.0 0.45 0.90 1.35 1.80 2.85 3.80 4.80 5.75 7.10 9.40 12.00 14.40 19.30 24.40

+2.0 0.40 0.80 1.20 1.60 2.68 3.58 4.60 5.50 6.70 8.80 11.50 13.70 18.60 23.85

40 25 30 30 65 65 65 65 75 100 125 150 200 250

Turndown 12:1 40:1 50:1 67:1 46:1 73:1 77:1 92:1 100:1 100:1 100:1 100:1 100:1 100:1

-5.0 4.5 5.5 4.9 6.1 7.3 7.5 4.5 7.4 8.1 9.8 12.0 9.1 8.7 12.3

-3.0 3.9 4.4 4.0 4.5 6.4 7.2 4.5 6.5 7.0 8.5 10.7 8.1 7.9 11.4

-1.0 2.8 3.4 3.0 3.5 5.4 6.1 4.0 5.8 5.9 6.9 9.4 7.0 7.0 10.5

0.0 2.3 2.8 2.5 2.9 4.9 5.5 3.7 5.4 5.3 6.3 8.8 6.5 6.5 10.1

+1.0 1.9 2.3 2.0 2.3 4.4 5.0 3.4 5.0 4.7 5.6 8.1 6.0 6.1 9.6

+2.0 1.5 1.8 1.6 1.9 3.9 4.4 3.1 4.5 4.2 4.9 7.4 5.4 5.6 9.2

Minimum " w.c. 7 8 11 16 12 17 14 20 12 14 20 22 30 38

Maximum psig

4

111 12222 2 2 2 2 2 2

666 66666 6 6 6 6 6 6

24 30 32 36 54 54 60 66 96 124 144 144 150 170

1/3 1/2 3/4 3/4 1-1/2 2 3 5 5 7-1/2 10 15 20 30

Chamber

Pressure

Inches w.c.

Chamber

Pressure

Inches w.c.

Maximum

Input,

Btu/hr.

In Millions

Gas Inlet

Press.

3

Chamber

Pressure

mbar

Gas Inlet

Press.

3

Minimum Input, Btu/hr. In 1000’s

1

High Fire

Gas ∆P,

2

"w.c.

Blower Motor HP

High Fire Flame Length, Inches

6

Min. Pilot Gas Press., " w.c.

5

Metric Units

High Fire

Gas ∆P,

2

mbar

Chamber

Pressure

mbar

Minimum Input, kW

1

Maximum

Input,

kW

High Fire Flame Length, m

6

Blower Motor HP

Min. Pilot Gas Press., mbar

5

Figure 1– Operating Parameters, Ratiomatics with Standard Blower & Motor

For natural gas, .65 s.g. Contact your Eclipse representative for propane data.

Capacities may be increased by 20% if sufficient secondary air is available to complete combustion.

14

6.0 Maintenance

Maintenance Program A sound preventative maintenance program, carried out by qualified individuals,

will greatly increase equipment reliability and productivity. Frequency of mainte-

nance checks should reflect the duty cycle of the heating equipment and condi-

tions such as dirt and temperature. Any maintenance program should include at

least the following steps:

Check Pressure Settings Check burner high and low fire air and gas settings.

Check Filters Examine and, if necessary, clean or replace air and gas filter elements.

Check Pipes for Leaks Check all piping connections for leaks.

Check Flame Supervision Equipment Check the ability of the flame supervision system to function properly by simulat-

ing system failures:

Simulate burner flame-out by manually shutting off the gas.

Trip out pressure switches and other limit interlocks.

Try to light the burner before the purge and other timers have finished their cycles.

If simulated limit or flame failures do not shut down the fuel system within an ac-

ceptably short period of time, immediately take the equipment out of service and

correct the problem.

Leak test automatic and manual reset fuel valves per insurance company procedures.

Check Bolts & Screws Check all bolts and screws for tightness.

Check for Overheating Check the area around the burner mounting flange for signs of overheating.

Gasket or insulation replacement may be necessary.

Figure 6–Filter Element Replacement

Blower

Housing

Gasket

Blower

Housing

#10-24 x 3/8" Long Screws

& Lockwashers (6)

Hold-Down Screws (4)

1/4 Turn to Release Ring

Filter Element

Retaining

Ring

Loading...

Loading...