12

Eclipse Winnox WX Series v1, Installation Guide No. 111, 8/26/05

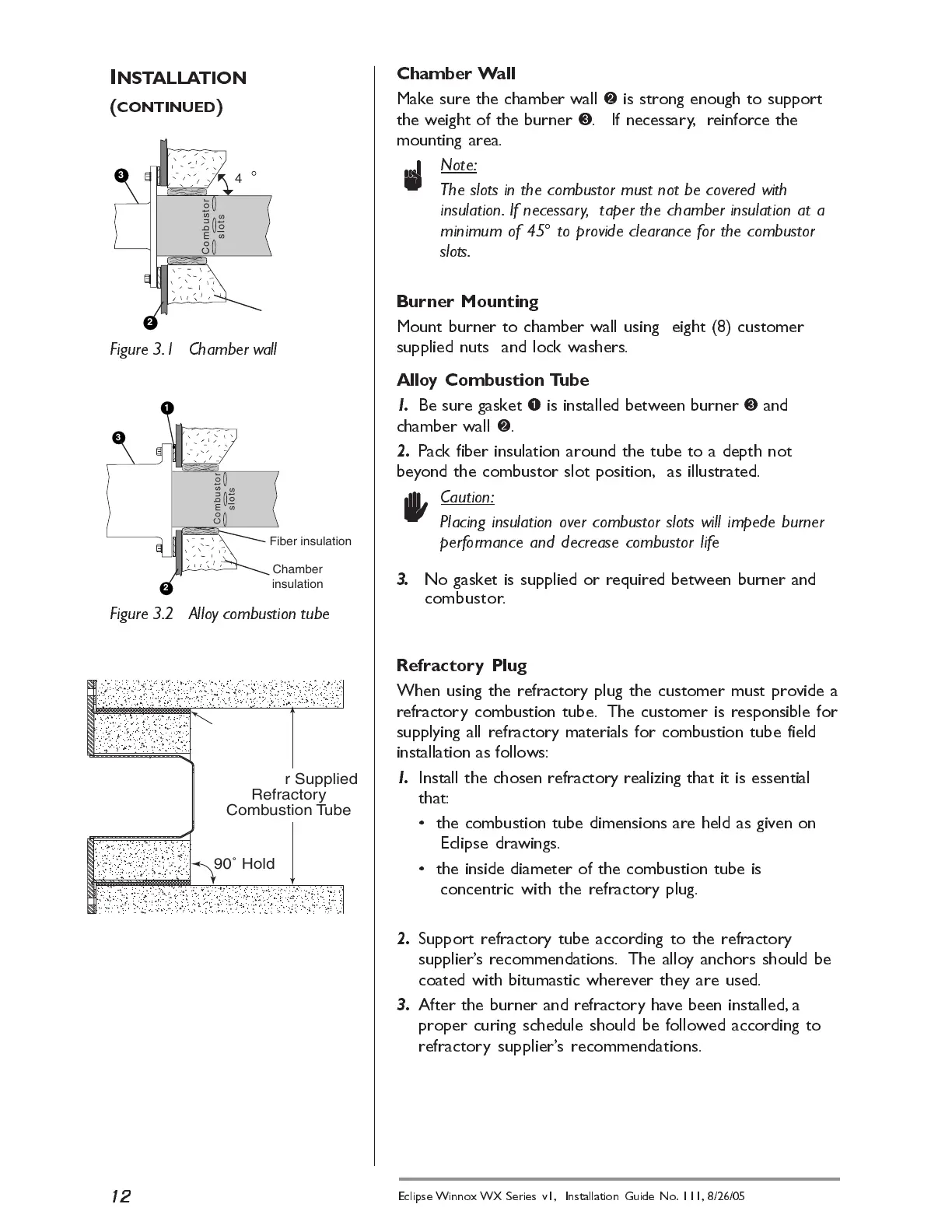

Fiber insulation

Chamber

insulation

1

3

2

Combustor

slots

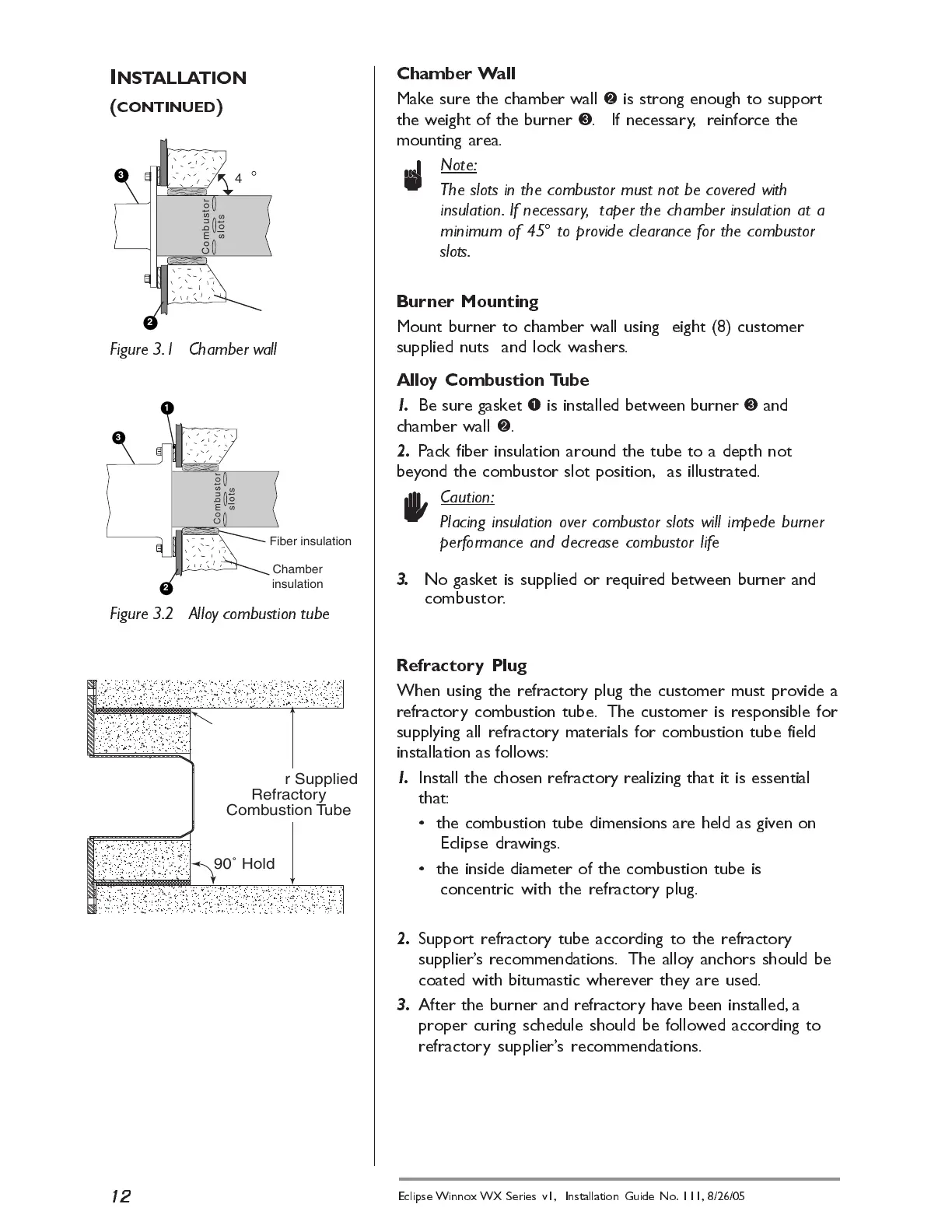

Chamber Wall

Make sure the chamber wall

2

is strong enough to support

the w eight of the burner

3

. If necessary, r einf orce the

mounting area.

n

Note:

The slots in the combustor must not be covered with

insulation. If necessary, taper the chamber insulation at a

minimum of 45° to provide clearance for the combustor

slots.

Burner Mounting

Mount burner to chamber wall using eight (8) customer

supplied nuts and lock washers.

Alloy Combustion Tube

1.

Be sure gasket

1

is installed between burner

3

and

chamber wall

2

.

2.

Pack fiber insulation around the tube to a depth not

beyond the combustor slot position, as illustrated.

c

Caution:

Placing insulation over combustor slots will impede burner

performance and decrease combustor life

3.

No gasket is supplied or required between burner and

combustor.

Figure 3.2 Alloy combustion tube

I

NSTALLATION

(

CONTINUED

)

Combustor

slots

3

2

45 Minimum

Chamber

insulation

Figure 3.1 Chamber wall

Refractory Plug

When using the refractory plug the customer must provide a

refractory combustion tube. The customer is responsible for

supplying all refractory materials for combustion tube field

installation as follows:

1.

Install the chosen refractory realizing that it is essential

that:

the combustion tube dimensions are held as given on

Eclipse dra wings.

the inside diameter of the combustion tube is

concentric with the refractory plug.

2.

Support refractory tube according to the refractory

suppliers recommendations. The alloy anchors should be

coated with bitumastic wherever they are used.

3.

After the burner and refractory have been installed, a

proper curing schedule should be followed according to

refractory suppliers recommendations.

Fiber

insulation

Customer Supplied

Refractory

Combustion Tube

90˚ Hold

Loading...

Loading...