pag.8

B

LB1007 Minor 20.1/30.1

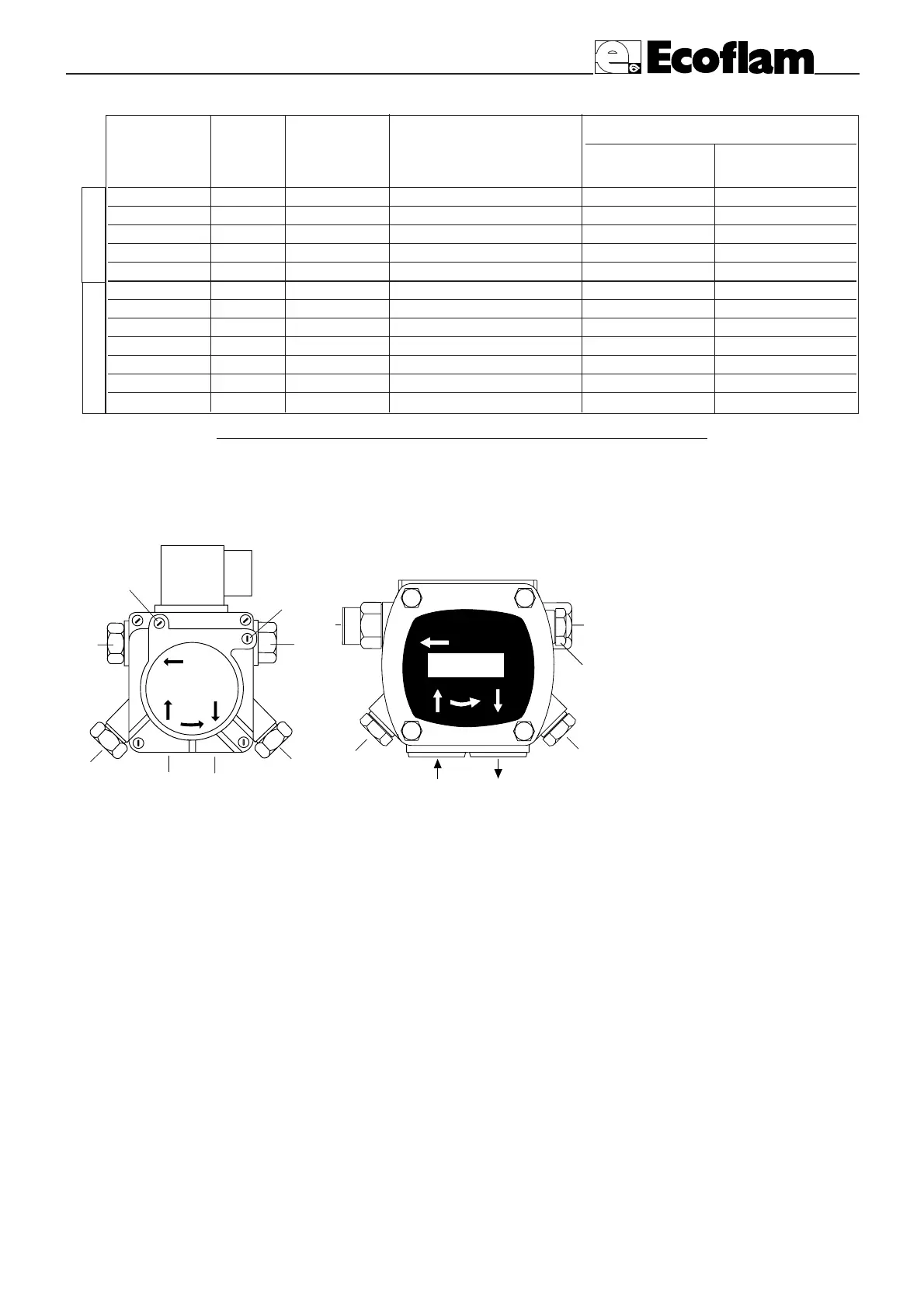

PRIMING AND ADJUSTMENT OF OIL PUMP

1- INLET

2- RETURN

3- BLEED AND PRESSURE

GAUGE PORT

4- VACUUM GAUGE PORT

5- PRESSURE ADJUSTMENT

6- TO NOZZLE

7 - CARTRIDGE FILTER

ADJUSTMENT DATA

NOZZLE : DANFOSS H÷S 80°÷60°; DELAVAN W 60°; STEINEN S 60°

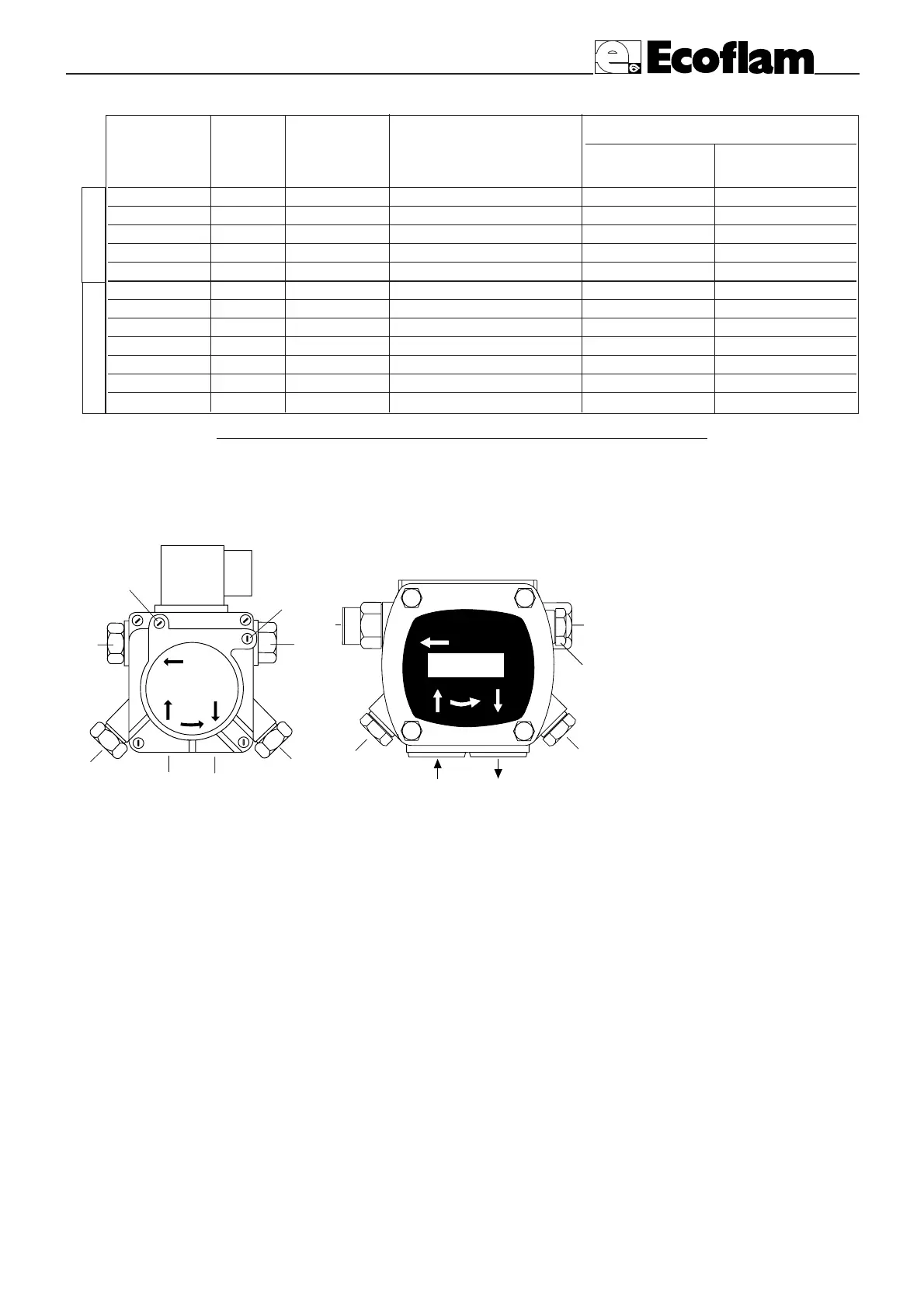

NOZZLE PUMP OUTPUT FIRING HEAD SETTING AIR DAMPER ADJUSTMENT

PRESSURE SIDE SUCTION SIDE

GPH Angolo BAR kg/h POS. Pos. Pos.

2.50 60° 12 10,4 - - MIN

3.00 60° 12 12,5 -

3.50 60° 12 14,9 -

4.00 60° 12 16,7 -

4.50 60° 12 19,1 - - MAX

3.50 60° 12 15,1 1 - MIN

4.00 60° 12 16,7 2

4.50 60° 12 19,1 3 ÷ 4

5.00 60° 12 21,8 4 ÷ 5

5.50 60° 12 23,6 5 ÷ 6

6.00 60° 12 25 6

6.50 60° 12 27,3 7 - MAX

MINOR 20.1-20.1R

MINOR 30.1-30.1R

VERIFY:

- That piping system is perfectly sealed;

- That the use of hoses is avoided whenever is possible (use copper pipes preferably);

- That depression is not greater than 0,45 bar, to avoid pump’s cavitation;

- That check valve is suitably designed for the duty;

The pump pressure is set at a value of 12 bar during the testing of burners. Before starting the burner, bleed

the air in the pump through the gauge port. Fill the piping with light-oil to facilitate the pump priming.

Start the burner and check the pump feeding pressure. In case the pump priming does not take place during

the first prepurging, with a consequent, subsequent lock-out of the burner, rearm the burner’s lock-out to

restart, by pushing the button on the control box. If, after a successful pump priming, the burner locks-out

after the prepurging, due to a fuel pressure drop in the pump, rearm the burner’s lock-out to restart the bur-

ner. Do never allow the pump working without oil for more than three minutes. Note: before starting the

burner, check that the return pipe is open. An eventual obstruction could damage the pump sealing device.

SUNTEC D57 A

Use only the suitable box wrench provided for this operation to remove the nozzle, taking care to not damage

the electrodes. Fit the new nozzle by the same care.

Note: Always check the position of electrodes after having replaced the nozzle (see illustration). A wrong posi-

tion could cause ignition troubles.

NOZZLE CLEANING AND REPLACEMENT

Loading...

Loading...