65

A039

Burning pot cleaning failure.

Sensors do not detect opening and closing of the

burning pot’s lid after 3 cleaning attempts.

• Doors or ash drawer cover badly closed.

• Burn pot base open or not properly closed.

• Sensor damaged.

• Wiring or connector disconnected or loose.

• Periphery damaged.

MODBUS RS485 communication error between

the CPU and its environment.

•

Broken cable, replace with a new one.

A041 Zoning Periphery 2

• Zoning Failure 2.

• MODBUS cable failure

A042 Zoning periphery 3

• Zoning fault 3.

• MODBUS cable failure

A051 Pneumatic Silo control without pellets

• External silo has no pellets.

• Pipeline.

•

A052

A053

Hopper silo 1 sensor without pellet.

• Sensor defective or badly calibrated.

• Without pellet.

• Conveyor screw of external silo stuck.

A054 Silo control 3 sensors

• One of the sensors damaged.

•

A055 Burning pot cleaning.

• Burning pot performing configured cleaning.

•

Burning pot cleaning carried out and awaiting

demand.

A099

Lack of pellets, impossible to reach the minimum

temperature for gas exhaustion (80 °C).

• Stopped gear motor.

• The safety thermostat has tripped.

Maximun flow temperature in zone 1.

• Little dissipation of the energy generated.

• Too heavily used.

Maximun flow temperature in zone 2.

A103 Maximun flow temperature in zone 3.

Minimum flow temperature in zone 1.

• Installation of boiler badly measured.

• Boiler working to low levels of power.

• Disconnected NTC.

Minimum flow temperature in zone 2.

A106 Minimum flow temperature in zone 3.

Maximun room temperature in zone 1.

• Too much temperature in the room.

• Disabling the room sensor.

•

Increasing operating temperature.

Maximun room temperature in zone 2.

Maximun room temperature in zone 3.

Minimum room temperature in zone 1.

• Low temperature in the room.

• Disabling the room sensor.

•

Lowering operating temperature.

Minimum room temperature in zone 2.

Minimum room temperature in zone 3.

A120

MODBUS RS485 communication error between

the CPU and its environment. Zone 1

• Disconnected cable.

• Broken cable, replace with a new one.

THT1 does not communicate.

• Review configuration.

• Check zone THT connections.

THT2 does not communicate.

THT3 does not communicate.

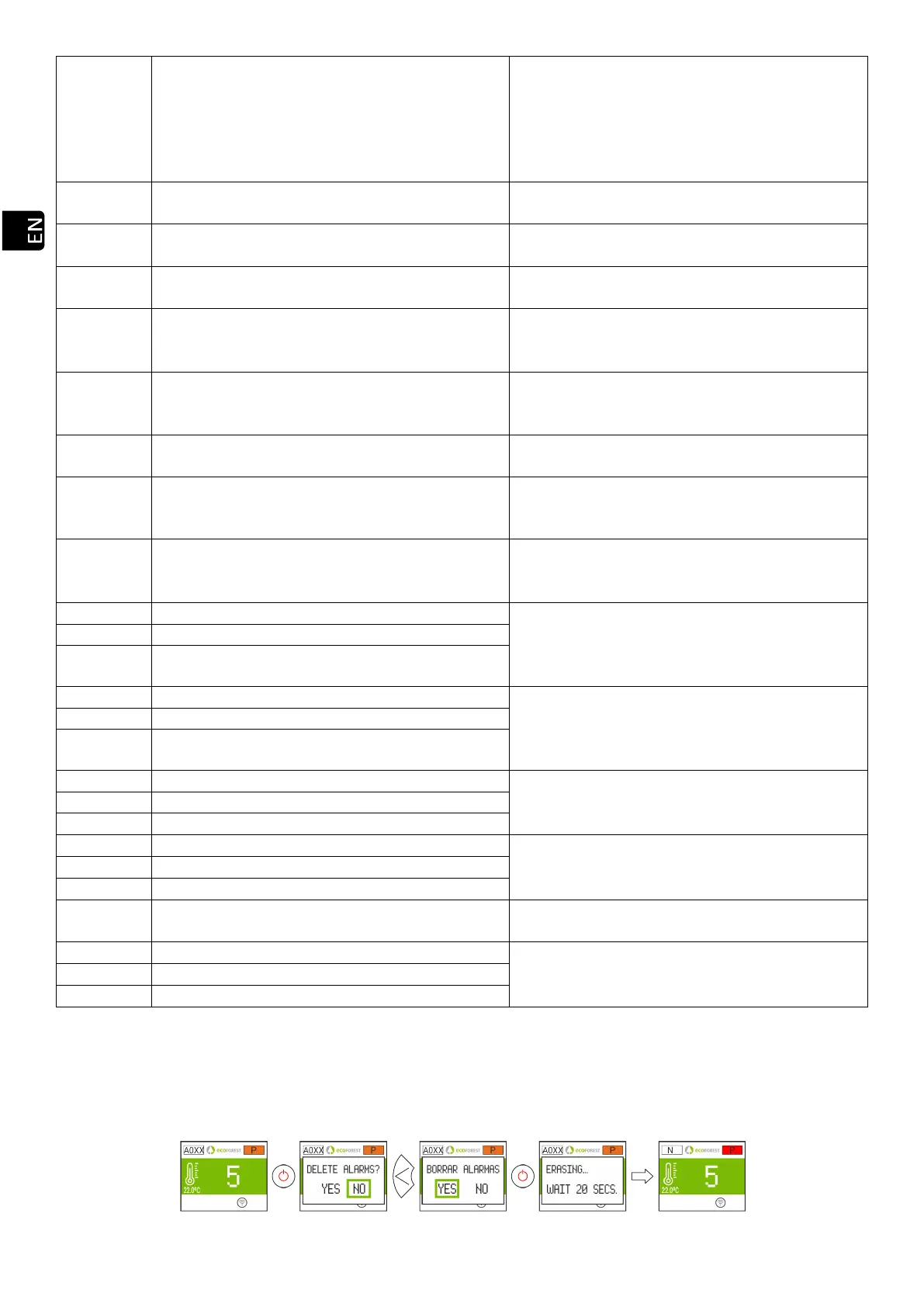

6.1. RESET ALARM.

The switching off process triggered by an alarm depends on the machine’s previous state, its configuration and

on a series of external factors. Once the alarm process has ended, the unit can be rebooted after having revised the

alarm table and taken the necessary measures.

Drawing 59

Loading...

Loading...