Heat

ptmp

bme

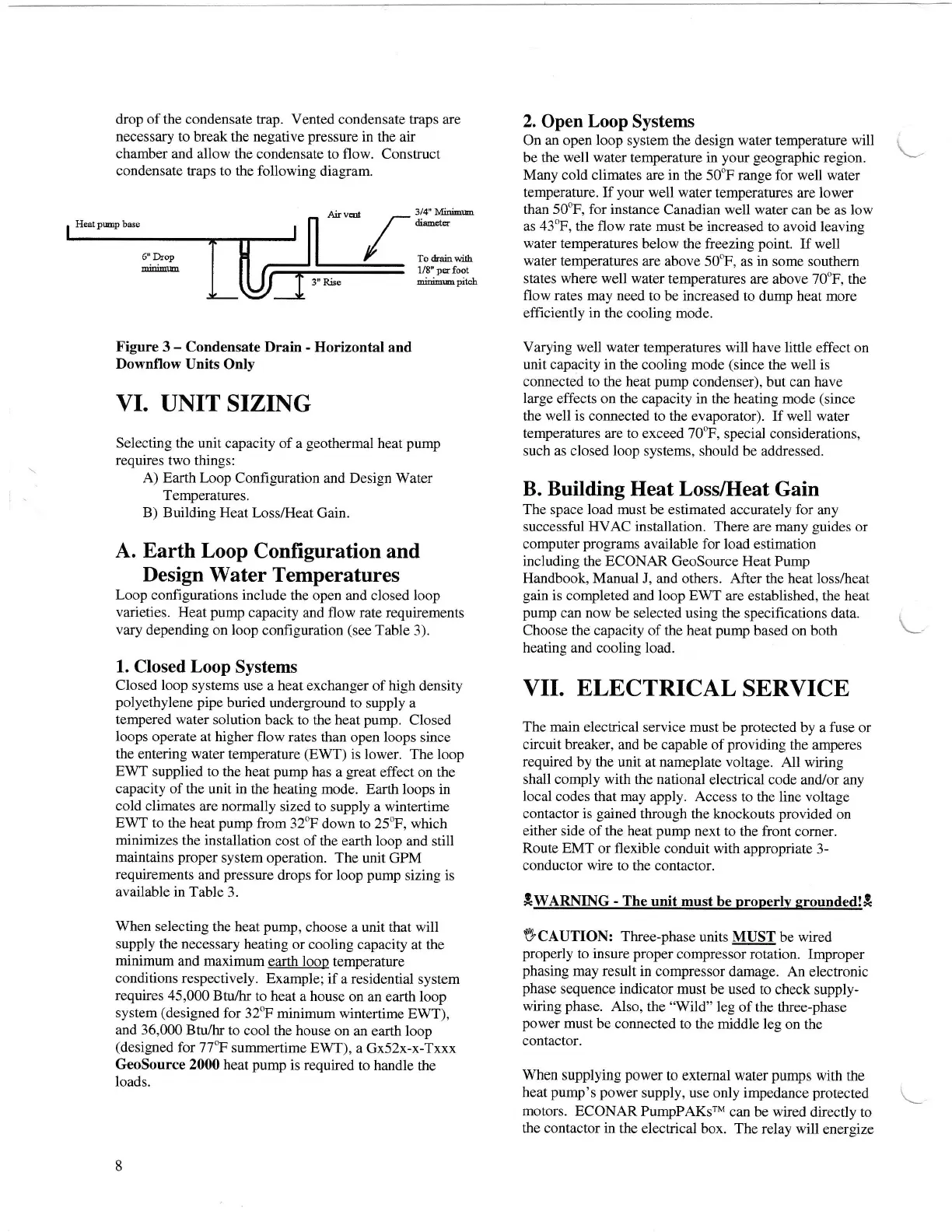

drop ofthe condensate

trap. Vented condensate traps are

necessary to break the negative

pressuro

in

the air

chamber and

allow the condensate to flow. Consffuct

condensate traps to

the following diagram.

Air v@t

3/4"Minim

di@til

2.

Open

Loop

Systems

On an open loop system the design water temperature will

be the well water temperature in

your geographic

region.

Many

cold climates are in the 50oF range for

well

water

temperature. If

your

well

water temperafures

are

lower

than 50oF, for instance

Canadian well water

can be as low

as

43nF,

the flow rate must

be

increased

to avoid leaving

water temperatures

below the freezing

point.

If well

water

temperatures are above

50oF, as in some southern

states

where

well water temperatures

are above 70oF, the

flow rates

may need to be increased

to dump heat more

efficiently

in

the cooling mode.

Varying well water temperatures

will have little effect on

unit capacity in

the cooling mode

(since

the well is

connected to the

heat

purp

condonser), but can have

large effects on the capacity in

the

heating

mode

(since

the well is connected to the

evaporator). If

well

water

temperafues are

to exceed 70oF, special considerations,

such as closed loop systems,

should be addressed.

B. Building Heat Loss/fleat

Gain

The space load must

be estimated accurately for any

successful

HVAC installation.

There are many

guides

or

computer

programs

available for load

estimation

including the ECONAR

GeoSource

Heat

Pump

Handbook, Manual

J, and others. After the heat loss/heat

gain

is completed

and

loop EWT

are established, the heat

pump

can now be selected

using the specifications data.

Choose the capacity of the heat

pump

based on both

heating

and cooling

load.

VII.

ELECTRICAL

SERVICE

The main

electrical service must be

protected

by a

fuse

or

circuitbreaker, and

be capable ofproviding the

amperes

required

by the unit at nameplate voltage.

All wiring

shall comply with the national

electrical code

and/or any

local codes that may

apply. Access to the line voltage

contactor is

gained

through the knockouts

provided

on

either

side of the

heat pump

next

to the front corner.

Route EMT

or flexible conduit with

appropriate 3-

conductor wire to the contactor.

9WARNING

-

The

unit must be

properlv

erounded!9

VCIUTION:

Three-phase

units

ry[WI

be wired

properly

to insure

proper

compressor rotation. Improper

phasing

may

result in compressor

damage. An

electronic

phase

sequence indicator

must be used

to check supply-

wiring

phase.

Also,

the

"Wild"

leg

of the three-phase

power

must

be connected

to the middle leg

on the

contactor.

When supplying

power

to extemal

water

pumps

with the

heat

pump's

power

supply, use

only impedance

protected

motors. ECONAR

PumpPAKsru

can be wired

directly to

the contactor in

the electrical

box. The relay will

energize

6" Drop

rinirm

To &aia wilh

1/8"

pafoot

niHffipitch

3" Rise

Figure

3

-

Condensate Drain

-

Horizontal and

Downflow

Units Only

VI. UNIT SIZING

Selecting

the unit capacity of a

geothermal

heat

pump

requires

two things:

A) Earth Loop

Configuration and Design Water

Temperafures.

B) Building

Heat Loss/Heat

Gain.

A. Earth Loop

Configuration and

Design

Water Temperatures

Loop configurations include

the open and closed loop

varieties. Heat

pump

capacity

and

flow rate

requirements

vary depending

on

loop

configuration

(see

Table

3).

1.

Closed

Loop

Systems

Closed loop

systems use a heat exchanger

of

high

density

polyethylene

pipe

buried underground to

supply a

tempered water

solution back to the heat

pump.

Closed

loops

operate at higher

flow rates than open loops

since

the entering waler

temperature

(EWT)

is lower. The loop

EWT

supplied to the heat

pump

has a

great

effect on the

capacity of

the unit in the heating mode.

Earth loops in

cold climates

are normally

sized to supply a wintertime

EWT to the heat

pump

from

32oF down to 25oF, which

minimizes

the installation

cost of the earth loop

and still

maintains

proper

system operation. The

unit GPM

requirements

and

pressure

drops

for

loop

pump

sizilg is

available

in Table

3.

When selectilg

the heat

pump,

choose a unit that

will

supply

the necessary heating

or cooling

capacity at the

minimum

and maximum

earth loop temperature

conditions

respectively.

Example; if

a

residential

system

requires 45,000

Btu/hr

to heat

a

house

on an earth loop

system

(designed

for

32oF minimum wintertime

EWT),

and 36,000

Btu/hr to

cool the house

on an earth loop

(designed

for 77oF

summertime EWT),

a Gx52x-x-Txxx

GeoSource 2000 heat

pump

is

required to handle

the

loads.

8

Loading...

Loading...