L

the PumpPAKrM with

a

call for heating

or cooling.

The

use of

impedance

protected pumps

eliminates

the need for

additional

fusing

on the PumpPAKrM.

VIII.

}AYOLT

CONTROL

CIRCUIT

The

wiring

diagrams in Figures 5 and

6 shows the

low

voltage controls of

the

heat

pump.

This section

will

break

down

the three

basic components of the low voltage

circuit; transformer,

thermostat, and controller.

A. Transformer

Electrical diagrams

are

provided

in Figures 5 and 6 and

on

the

electrical box cover

panel

of the

GeoSource

20(X)

heat

pump.

An internal 24-volt,55

VA transformer

is

provided

to operate

all

control features

of the

heat

pump.

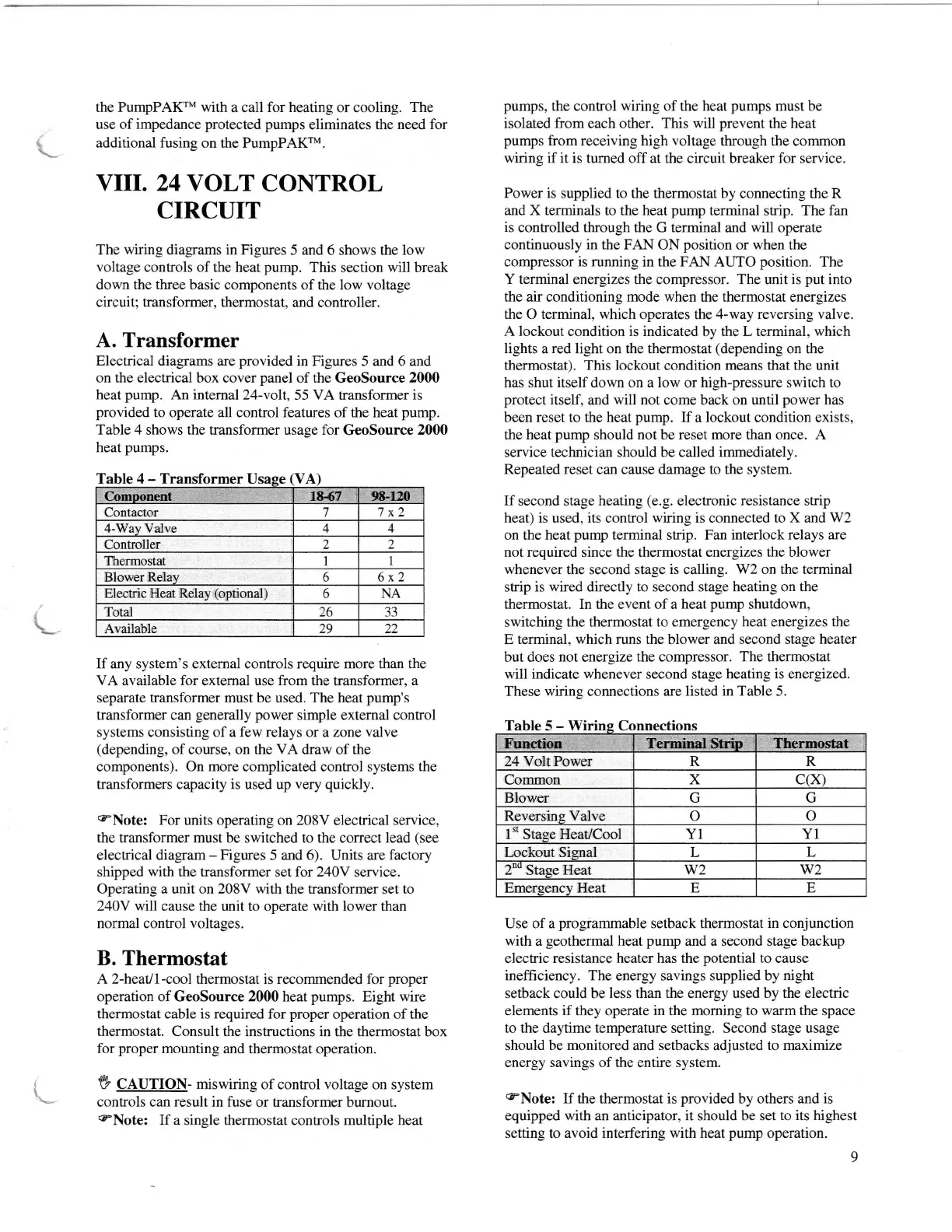

Table

4

shows the transformer usase for

GeoSource

2000

heat

pumps.

Table

4

-

Transformer

If any system's external controls require more than the

VA available for

external

use from

the transformer,

a

separate

transformer

must be

used. The

heat

pump's

transformer can

generally power

simple external control

systems consisting of a few relays or a zone

valve

(depending,

of

course, on

the VA

draw of the

components).

On more

complicated control

systems the

transformers capacity is used up very

quickly.

cNote:

For units operating on 208V

electrical

service,

the transformer must be switched to the

correct

lead

(see

electrical

diagram

-

Figures 5 and 6).

Units

are factory

shipped

with

the transformer set for 240V

service.

Operating a unit on 208V

with

the transformer set to

240V

will

cause the unit to operate with lower than

normal control

voltages.

B. Thermostat

A2-heatll-cool thermostat is recommended for

proper

operation of GeoSource 2fi)0 heat

pumps.

Eight

wire

thermostat cable is required for

proper

operation of the

thermostat. Consult

the instructions in the thermostat box

for

proper

mounting

and

thermostat

operation.

V C.LUffON- miswiring of control voltage on system

controls can

result

in fuse or transformer

burnout.

eNote:

If

a single thermostat controls multiple heat

pumps,

the control wiring of the heat

pumps

must be

isolated from

each other. This

will

prevent

the

heat

pumps

from receiving high voltage

through the common

wiring if it is tumed off at the

circuit breaker

for service.

Power is

supplied

to the thermostat

by connecting the R

and X terminals

to the

heat

pump

terminal strip. The fan

is

controlled through the G terminal

and

will operate

continuously in

the

FAN

ON

position

or

when

the

compressor is

running

in the FAN

AI-ftO

position.

The

Y terminal

energizes the compressor.

The

unit is

put

into

the

air conditioning

mode

when the thermostat energizes

the O terminal, which operates

the

4-way reversing valve.

A lockout condition is indicated

by the

L terminal, which

lights

a

red

light on

the

thermostat

(depending

on the

thermostat). This lockout condition means that the unit

has shut itself

down

on a low

or

high-pressure switch to

protect

itself,

and

will not

come back on

until

power

has

been reset

to the heat

pump.

If a

lockout condition

exists,

the heat

pump

should not be reset more than once. A

service technician should be called immediately.

Repeated reset

can

cause dama-ee to

the

system.

If

second stage heating

(e.g.

electronic

resistance

strip

heat) is used, its control

wiring

is connected to

X

and

W2

on the heat

pump

terminal strip. Fan interlock

relays are

not required

since

the thermostat energizes the blower

whenever

the second

stage is

calling.

W2 on the terminal

strip is wired directly to second stage heating on the

thermostat. In the event of a

heat

pump

shutdown,

switching the thermostat

to emergency heat energizes the

E terminal, which runs the blower and second stage heater

but does

not

energize

the compressor. The thermostat

will indicate whenever second

stage

heating

is

energized.

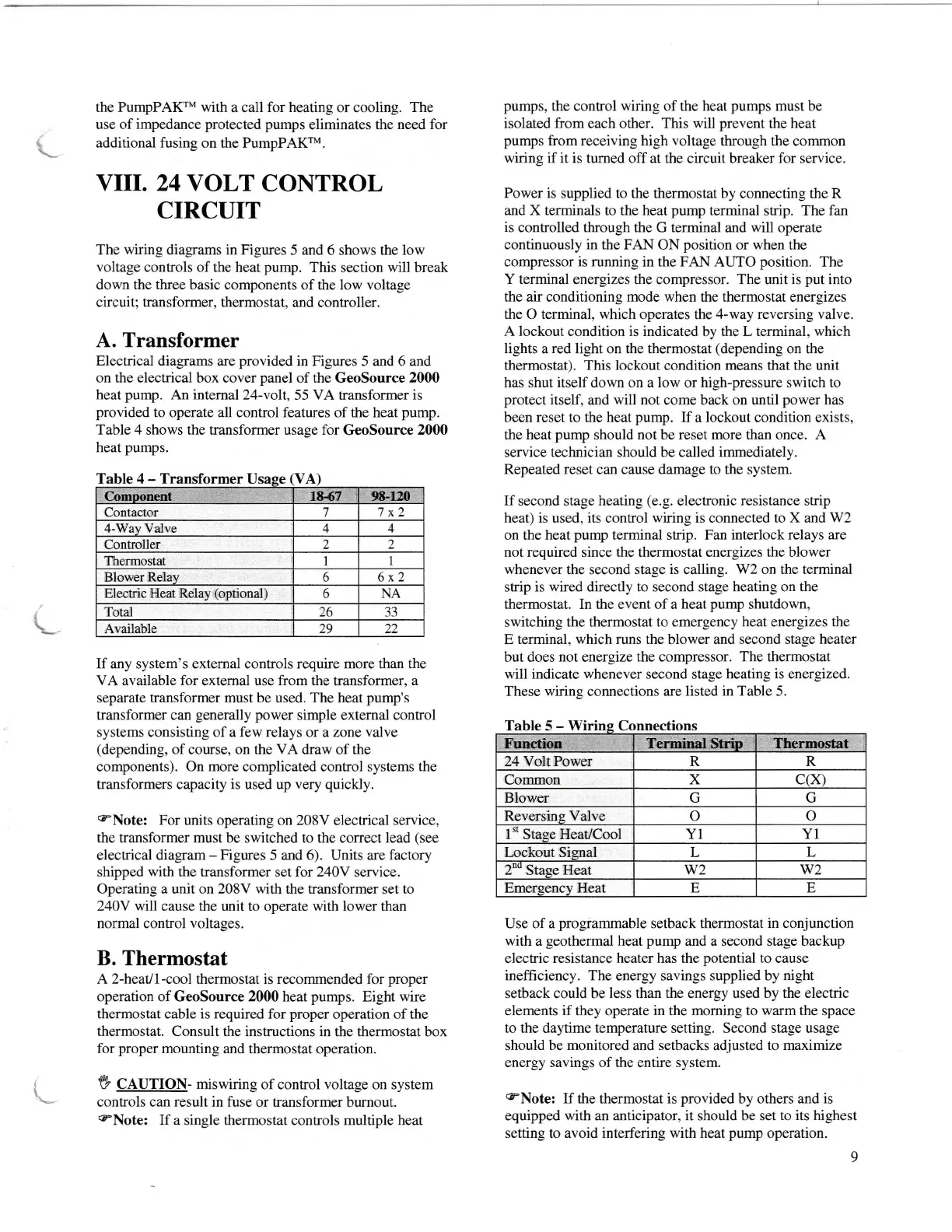

These wiring

connections are

listed in Table 5.

Table

5

-

Connections

Use of a

programmable

setback thermostat

in

conjunction

with a

geothermal

heat

pump

and a second stage backup

electric resistance heater has the

potential

to

cause

inefficiency. The energy savings supplied by

ni-eht

setback could be

less than the

energy

used by the electric

elements if

they operate

in the moming to warm the

space

to the daytime temperature setting. Second stage usage

should be monitored and setbacks

adjusted

to maximize

energy savings of the entire system.

eNote:

If

the thermostat

is

provided

by others and

is

equipped

with

an anticipator, it should be set to

its highest

setting to

avoid interfering

with heat

pump

operation.

9

Contactor 1

7 x2

4-Way Valve

4

4

Controller

')

2

Thermostat I

1

Blower Relay

6

6x2

Electric Heat Relay

(optional)

6

NA

Total 26

JJ

Available

29 22

R R24 Volt Power

Common x c(x)

Blower G G

Reversing

Valve o o

1"

Stase Heat/Cool Y1

YI

Lockout Sisnal L

L

2oo

Stage

Heat w2 w2

Emergency

Heat

E E

\

L

Comoonent 18{7 98-12{'

Functiog Terminal Strip Tlrermostat

Loading...

Loading...