26 27

This manual is the intellectual property of Ecoso. Copying and reprinng is prohibited. © 2024

INSTALLATION AND OPERATION GUIDELINES FOR REVERSE OSMOSIS SYSTEMS ECOSOFT ROBUST MINI,

ROBUST 1500, ROBUST PRO, ROBUST 3000, ROBUST 3000MAX, ROBUST 4000

ENG

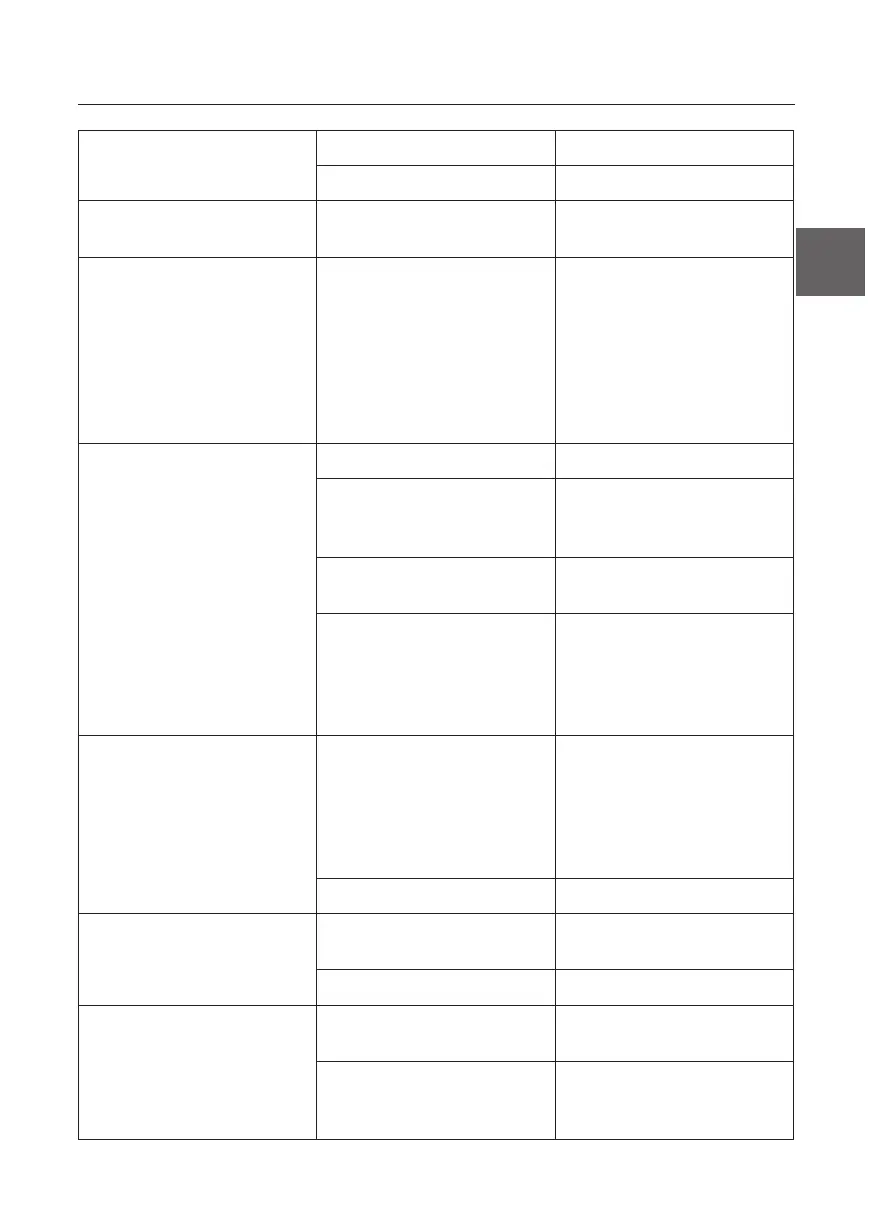

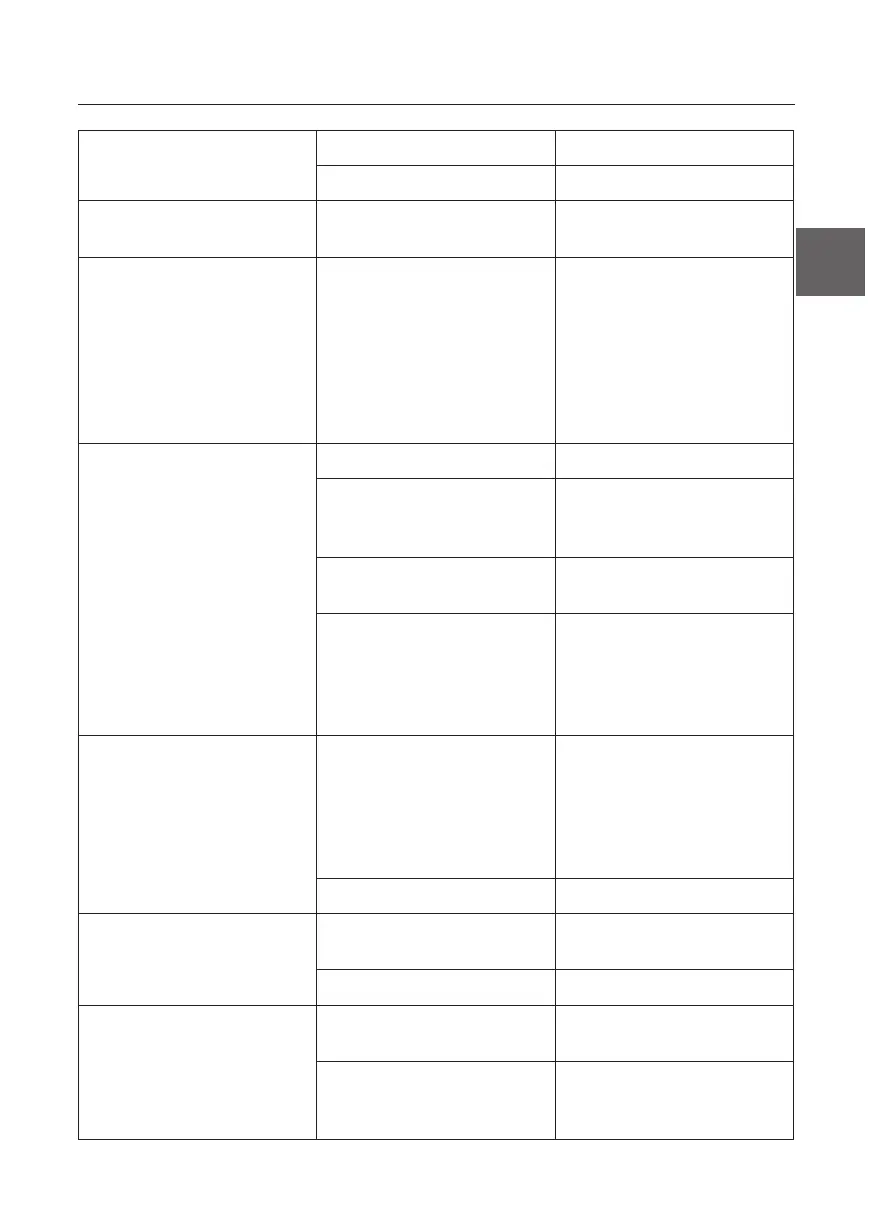

Recovery has decreased

signicantly

Clogged pre-lter Replace pre-lter

Clogged membranes Replace membranes

Water is not discharged to

drain when the system is on

Clogged ow restrictor Clean ow restrictor or re-

place if necessary

Puried water is hazy or

cloudy but becomes clear

aer a few minutes

Air bubbles trapped in the

system

Some air may remain in the

system for a few days aer

installaon and will go away

on its own.

Air bubbles may appear in

water if there is a large dier-

ence between feed water and

ambient temperature

Puried water has a taste or

odor

Expired post-lter Replace post-lter

Membrane preservave was

not ushed fully aer the

installaon

Flush the RO system and

discard all rinse water

Contaminaon of the system Sanize the system according

to instrucons in p. 7

Contaminaon of pressure

tank

Sanize pressure tank.

Pressure tank may become

contaminated if lters or

membranes are used beyond

their service life

Pressure tank is not full when

the system switches o

Tank bladder is overinated Pressure in empty tank

bladder must be 0.6–1.0 atm.

Release some pressure if

necessary.

Operaon is performed by

water lter service specialist

Tank valve is closed Check tank valve posion

Mineralizaon aer RObust

Pro decreased

Flow resctor aer Pro lter

is clogged

Clean up ow resctor aer

Pro lter

Resource of Pro lter is o Replace Pro lter

The operang pressure is

higher than 8 bar

The lifeme of the membrane

elements has ended

Replace all lters, including

membrane elements

The bypass on the pump is

not regulated

Regulate the bypass on the

pump to a pressure value of

6-7 bar

Loading...

Loading...