1)

2)

3)

4)

5)

6)

7)

Check the connection between power supply plug and socket

and ground wiring regularly;

In cold area

(

below 0°C

), if the system will be stopped for

a long time, all the water should be

in case of freezing

of inner tank and damage

E-heater.

It is recommended to clean the inner tank and E-heater every

half year to keep an e

cient performance.

Check the anode every year and change if required. For

more details, please contact the supplier or after-sale

service.

It is recommended to set a lower temperature to decrease the

heat release, prevent scale and save energy if the outlet water

volume is su

nt.

Clean the air

lter every month in case of any ine ciency

the

heating performance.

t

Be fore shutting the system of f for a long time,

Release all the water in water tank and the pipeline and close

all the valves

Check the inner components regularly.

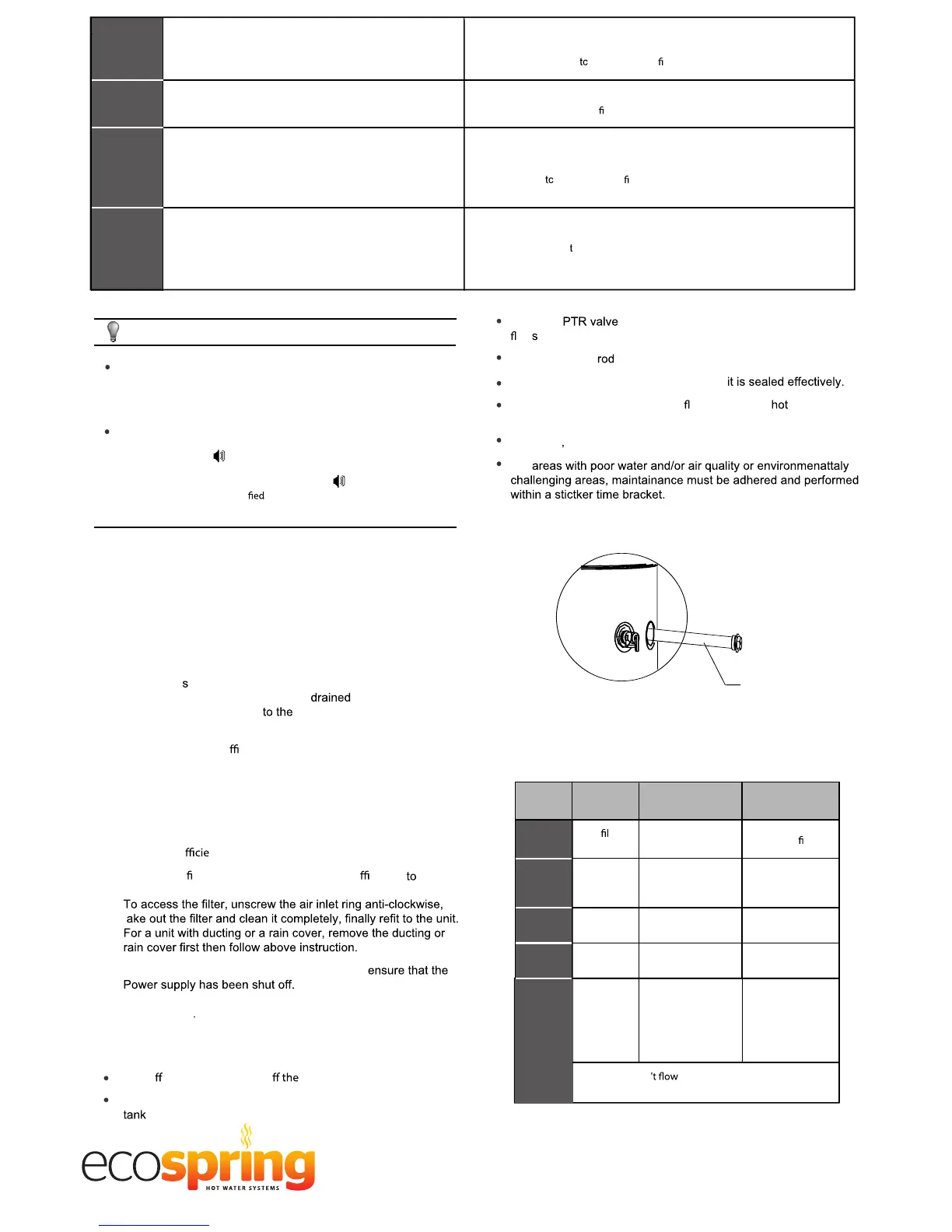

How to change the anode;

Turn o

the power, and turn o water inlet valve.

Open hot water tap, and decrease the pressure of the inner

.

8)

P2

High discharge temperature protection

Tp>110°C Protection active

Tp<90

Protection inactive

°C

P3

P4

LA

It is normal, and no

necessary to repair.

Open the , and release the water, until no water

ow out.

Unscrew anode

.

Replace with a new one, and make sure

Open cold water valve untill water ows out from outlet tap,

then turn of water outlet tap.

Power on

then restart the unit.

Checking

Item

Checking

content

Checking frequency Action

1

air

ter

(inlet/outlet)

every month Clean the

lter

2 anode every year

Re place it if it has

been used out

3 inner tank every year Clean the tank

4

5

E-hea ter every year Clean E-heater

Operate t he

hander of PTR

valve to ensure

that waterways

are clear.

PTR valve

If water doesn

freely when operating the

hander, replace PTR valve with a new one

every year

Table . 10.2

anode

For

Compressor abnormally stopped protection.The discharge

temperature is not so higher than evaporator temperature

after compressor running a term.

Compressor overloaded protection (10 secs after compres-

sor startup, current checking starts, 1) only compressor

running, if it is >10A , the compressor will be stopped and

protected. 2) Compressor+E-heater running, if it is

>IEH+10,the compressor will be stopped and p

rotected.)

When the ambient temp T4 is out of Heat Pump running

range (-7 〜43°C) Heat Pump will stop, unit will show LA on

the position of clock on display until T4 back to (-7 〜43°C).

Only valid for the unit without E-heater.Unit with E-heater

will never show "LA".

System blocked, air or water or less

refrigerant(leakage) in system( after repair), water temperature

sensor malfunction, e

. Contact a quali ed person to service the unit.

Compressor b roken or bad connection between PCB and

compressor.Contact a quali

ed person to service the unit.

Maybe because of compressor broken, system blocked, air or water

or more refrigerant in system(after repair),water temperature sensor

malfunction, e

. Contact a quali ed person to service the unit.

The diagnostic codes listed above are the most com mon. If a

diagnostic code not listed above is displayed, contact residen-

tial technical assistance referenceing the number on the front

of this manual.

If any of P3/P4/P2/P1 continuously appear 3 times within single

heating cycle, system will consider it as “Heat Pump system error”. The

third failure code and will be shown on the display, then heat pump

will stop running,and the unit will shift automatically to E-heater as the

backup heat source,but the third failure code and will be shown until

power is reset.Contact a quali

person to service the unit.

NOTE

10. MAINTENANCE

10.1 Maintenance

10.2 Recomended Maintenance Table

Loading...

Loading...