3. Totally drain the oil tank using a suitable extraction system (used oil extraction pump)

so that no oil can leak into the machine;

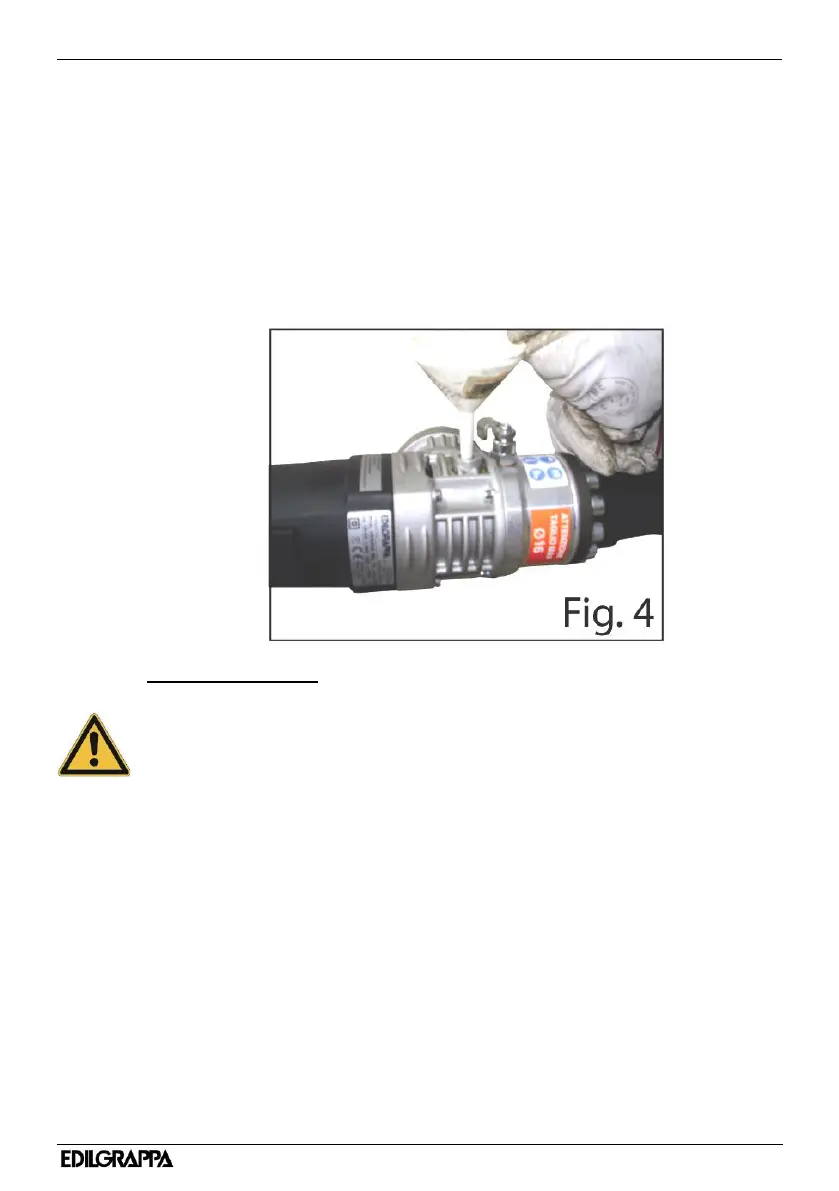

4. Slowly pour in the correct quantity of oil (0.6 l) using suitable equipment (e.g. a funnel

as shown in fig. 4). Only use new or clean recommended oil (as indicated on the next

page);

5. Fill up to the upper rim of the hole;

6. Put back the oil cap and tighten slightly;

7. Perform some piston strokes to vent the large air bubbles;

8. Move the piston to its maximum extension and rapidly start and stop the motor several

times (before the piston automatically retracts);

9. Complete filling;

10. Put the oil cap on and tighten.

TOPPING UP THE OIL:

Before unscrewing the magnetic cap to check the oil level, make sure the piston is

fully extended and, if necessary, pull it out. If this is not done the oil may leak, air

bubbles may form and/or the oil level may be incorrectly measured, thus causing

the machine to operate incorrectly.

Only after completing the above operations, proceed as shown below:

1. Place the machine horizontally in a stable position on a work surface with the filling

hole facing upwards. Place a basin under the machine to catch any oil leaks;

2.

Unscrew the magnetic cap (see part. 8 para 0.01) and remove any residues;

3. Check the amount of missing oil;

4. Slowly top up to the upper rim of the hole with recommended new and clean oil using

suitable equipment (e.g.: a funnel as indicated in fig. 4);

5. Put the oil cap on and tighten.

Maximum quantity: 0.6 l.

Type of hydraulic oil: ESSO NUTO H46 or

approved equivalents HLP46

according to DIN 51 524 MIL-H 17672 C

Loading...

Loading...