3.04 CHECKING TOOLS

The use of worn tools decreases the potential of the machine and can needlessly

overheat the motor.

REPLACE AS SOON AS YOU NOTICE THEY ARE WORN.

REPLACING TOOLS:

Disconnect the tool, place it horizontally on a stable worktop and proceed as follows:

BENDING ROLLER:

1. Fully return the piston to position 1 ( open ) using the double-acting lever, see para 2.03;

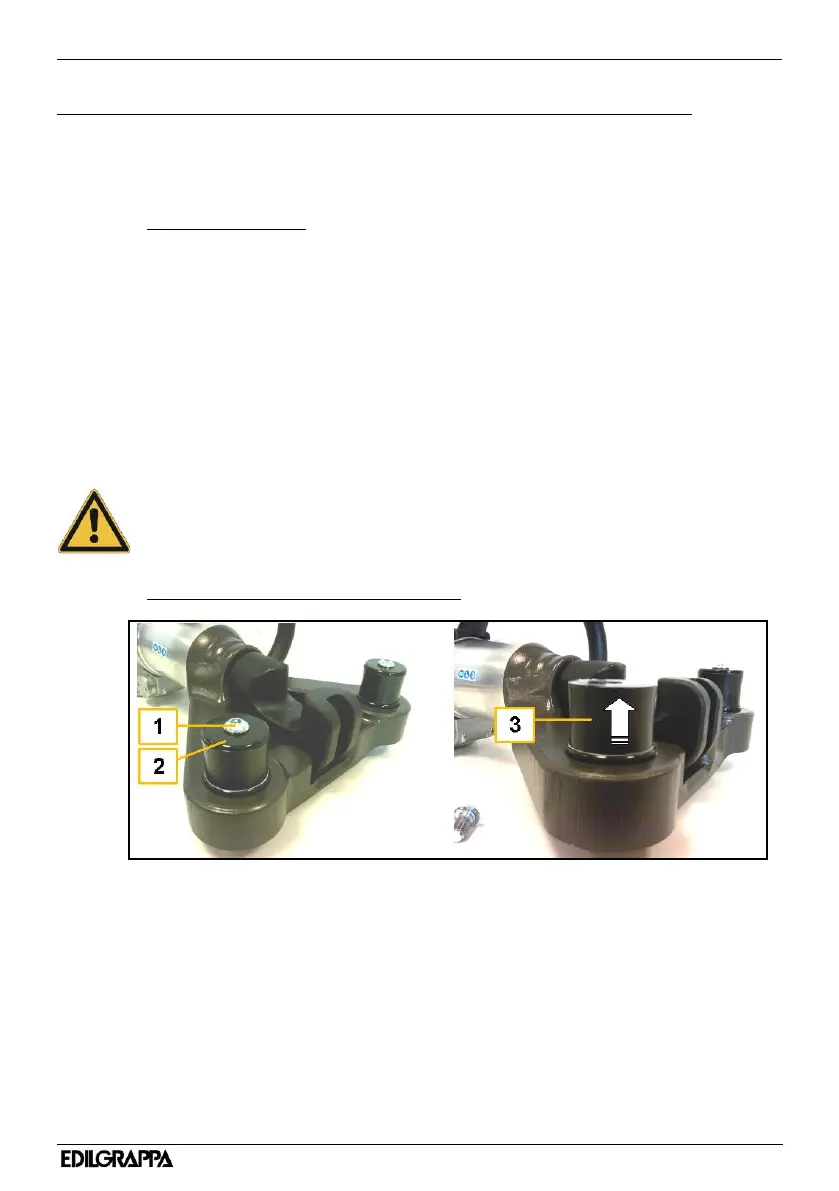

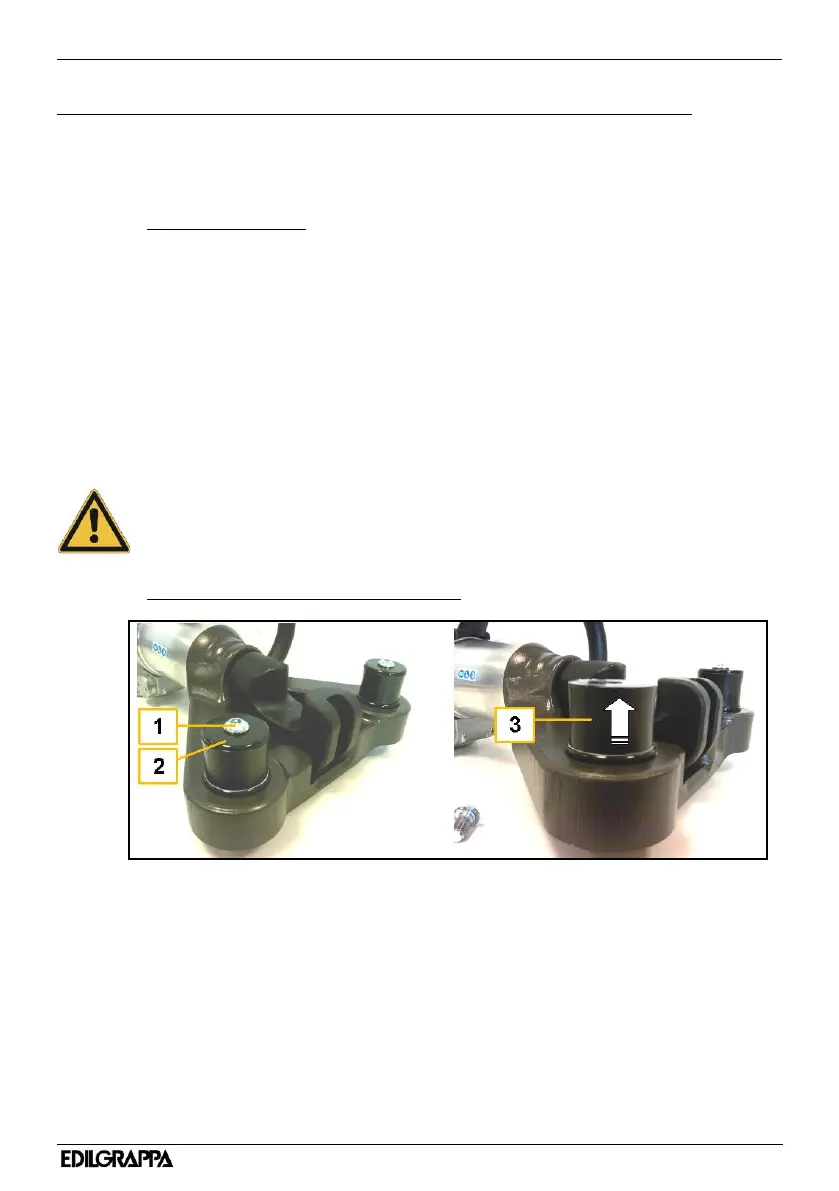

2. Remove the lock screw ( see ref. 1 in fig. 5A );

3. Remove the washer ( see ref. 2 in fig. 5A);

4. Remove the bending roller ( ref. 3 in fig. 5A ) as indicated by the arrow ( fig. 5A );

5. Mount the new bending roller;

6. Put back the washer;

7. Fully tighten the lock screw.

The following picture (Fig. 5A) is only an example

Fig. 5A

CAM SUPPORT:

The cam support is made from material with a high mechanical resistance and heat

treated to assure a long lifetime whilst considerably reducing the need to replace it.

To replace the cam support, contact the manufacturer.

Loading...

Loading...