Suggestions & Reminders

1. Always use an EFD piston to make your barrel loading,

dispensing and handling cleaner, safer and more accurate.

Caution: If you dispense watery-thin fluids and choose not to use

SmoothFlow

™

pistons – do not increase vacuum pressure

rapidly and do not tip the barrel. Vacuum may pull liquid into the

air hose; or when tipped, liquid may flow back into the dispenser.

2. Always use new barrels and tips. Carefully dispose of after

use. This procedure ensures maximum cleanliness, pre-

vents contamination and provides proper safety.

3. Do not completely fill the barrel. For most fluids, optimum fill

is a maximum 2/3 of the barrel capacity. For cyanoacrylates

or watery-thin fluids, optimum fill is 1/2 of the barrel capacity.

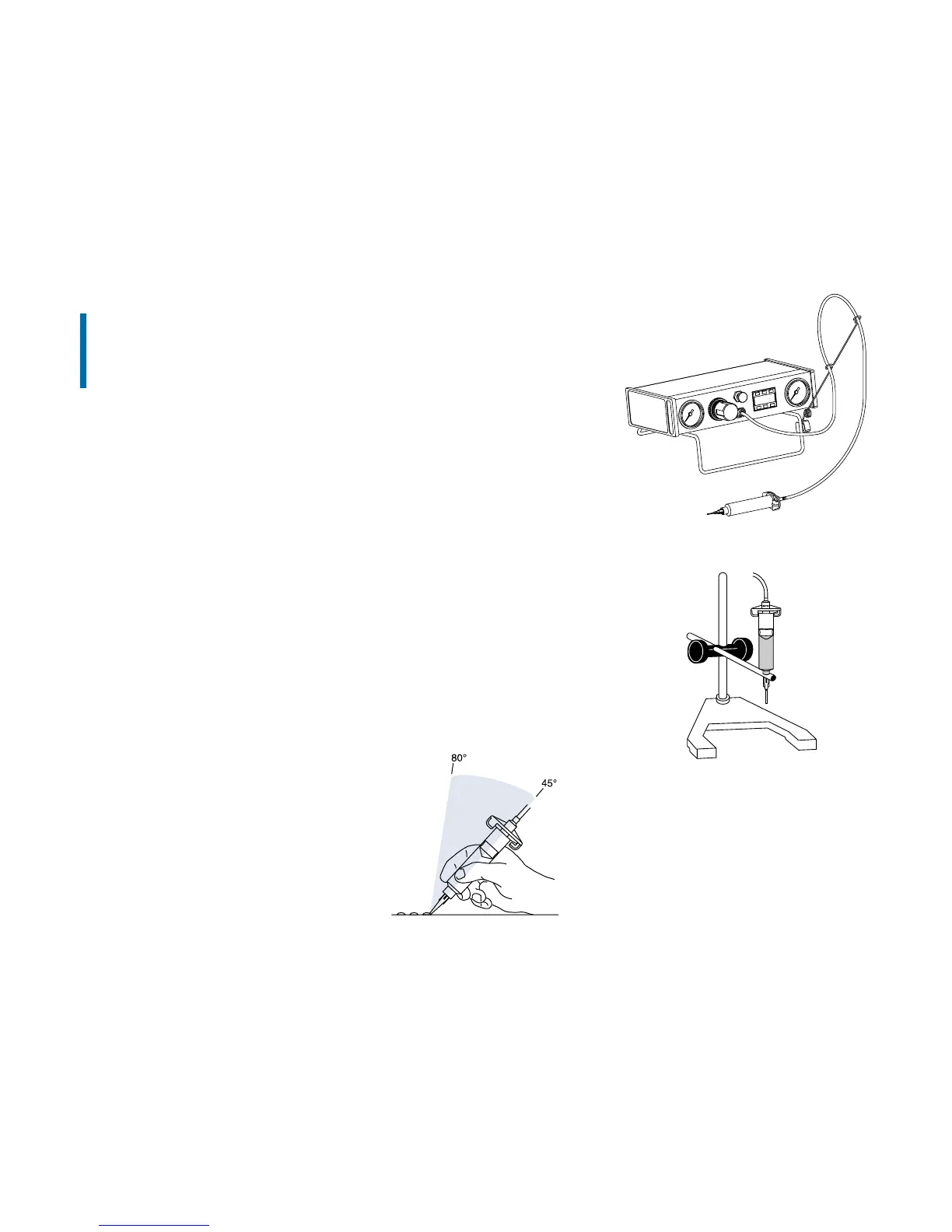

4. Use the EFD #DS1200 DispenStand

™

to help organize

bench space. Adapter hose support keeps hose off of the

work area. See illustration.

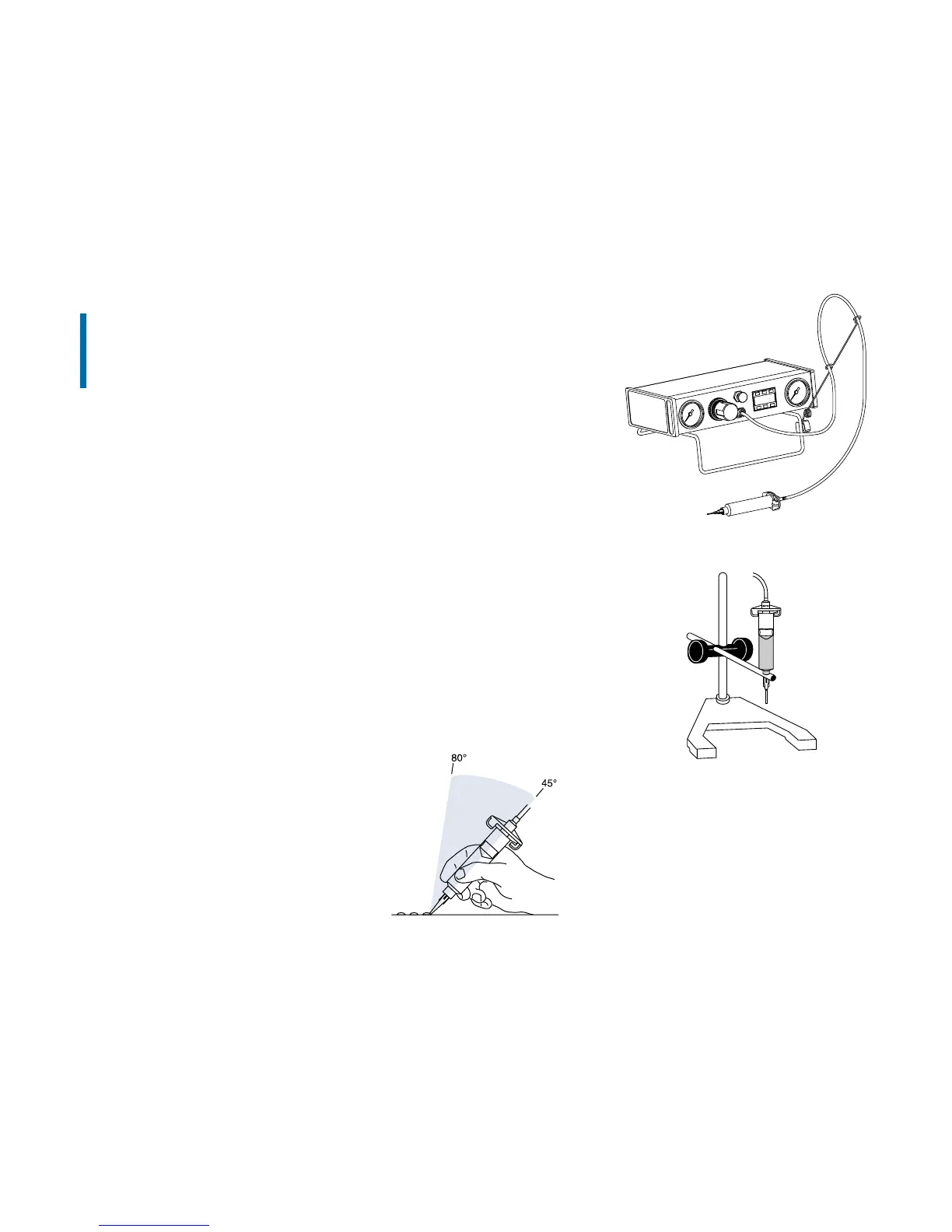

5. Depending on the type of work you are doing, it may be

easier to bring the work to the barrel. Mount the barrel on a

stand such as the EFD #7300A.

6. To ensure smooth fluid flow and to make consistent depos-

its, always have the tip at about a 45° angle to the work

surface.

#7300A

Barrel Stand

#DS1200

DispenStand

™

Loading...

Loading...