TROUBLESHOOTING

CHECKING THE EFFICIENCY OF THE COMPONENTS

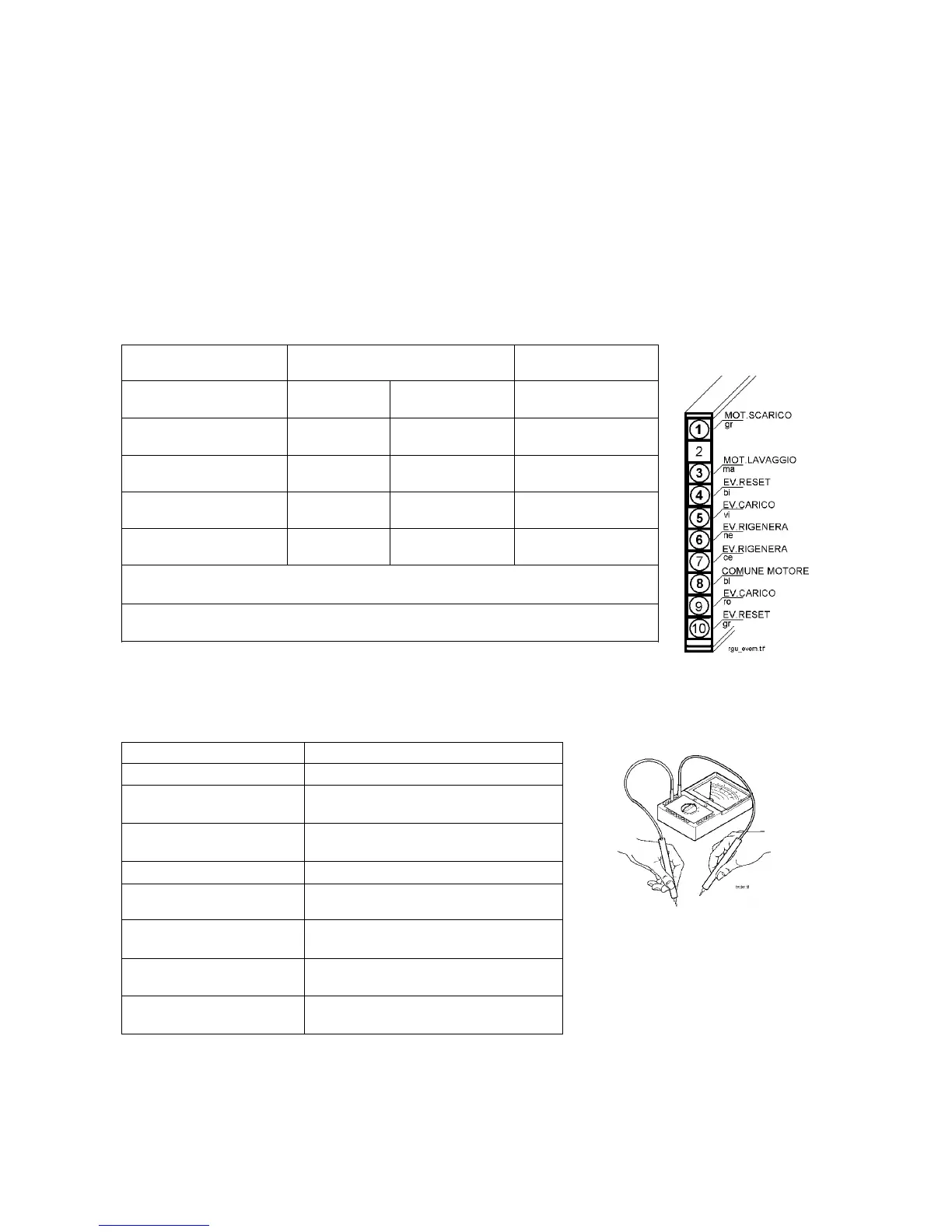

In order to facilitate checking of the efficiency of the component to be tested, a special CONTROL

PROCEDURE has been created. The contacts to which the tester should be applied and the correct

resistance for each component are shown in the table below.

After detaching the modular wiring connector fitted to the bottom of the appliance, measure the resistance

to verify the efficiency of the components fitted to the dishwasher.

TRADITIONAL DISHWASHERS (ELECTROMECHANICAL TIMER)

PROCEDURE: Apply the probes of the tester to the points indicated and measure the resistance.

COMPONENT TESTER PROBES

CONNECTION / COLOUR

CORRECT VALUE

MOTOR

( Drain )

1 - 8

Grey - Blue

73 Ω

ΩΩ

Ω ± 7%

MOTOR

( Washing )

3 - 8

Brown - Blue

48 Ω

ΩΩ

Ω ± 7%

REGENERATION

SOLENOID

6 - 7

Black - Light blue

5200 Ω

ΩΩ

Ω ± 8%

FILL SOLENOID AND

ANTI-FLOODING DEVICE

5 - 9

Purple -Pink

3950 Ω

ΩΩ

Ω ± 8%

RESET

SOLENOID

4 - 10

White - Grey

5200 Ω

ΩΩ

Ω ± 8%

N.B. If the resistance measured across contacts 1 - 8 and 3 - 8 is the same

(28 Ω

ΩΩ

Ω approx.), this means that the capacitor is short-circuited.

KEY: ar = orange bi = white bl = blue ce = light blue gr = grey

ma = brown ne = black ro = pink vi = purple

The remaining components can be tested in the same way or directly on the components themselves.

The correct values are listed below:

COMPONENT CORRECT VALUE

DOOR MICROSWITCH

Door closed 0 W

PRESSURE SWITCH

Empty (1-2) INFINITE

Full (1-3) 0 W

HEATING ELEMENT AND

SAFETY THERMOSTAT

2300 W 25 W ± 8%

FAN MOTOR

720 W ± 8%

INTEGRATED DETERGENT

DISPENSER

1300 W ± 8%

TEMPERATURE CONTROL

THERMOSTAT(S)

Open INFINITE

Closed 0 W

SALT SENSOR

With salt INFINITE

Without salt 0 W

RINSE-AID SENSOR

With rinse-aid INFINITE

Without rinse-aid 0 W

26

Loading...

Loading...