WATER FILL SAFETY SYSTEMS

These safety systems detect any possible malfunctions that might result from incorrect operation of the

hydraulic circuit or leakage from any of the components.

The electromechanical/hydraulic safety devices are always operative during the washing cycle and, in

some cases, even when the appliance is switched off.

These devices are fitted to dishwashers with both Electromechanical and Electronic control systems.

ANTI-FLOODING device

ANTI-OVERFLOW device

ACQUASTOP device

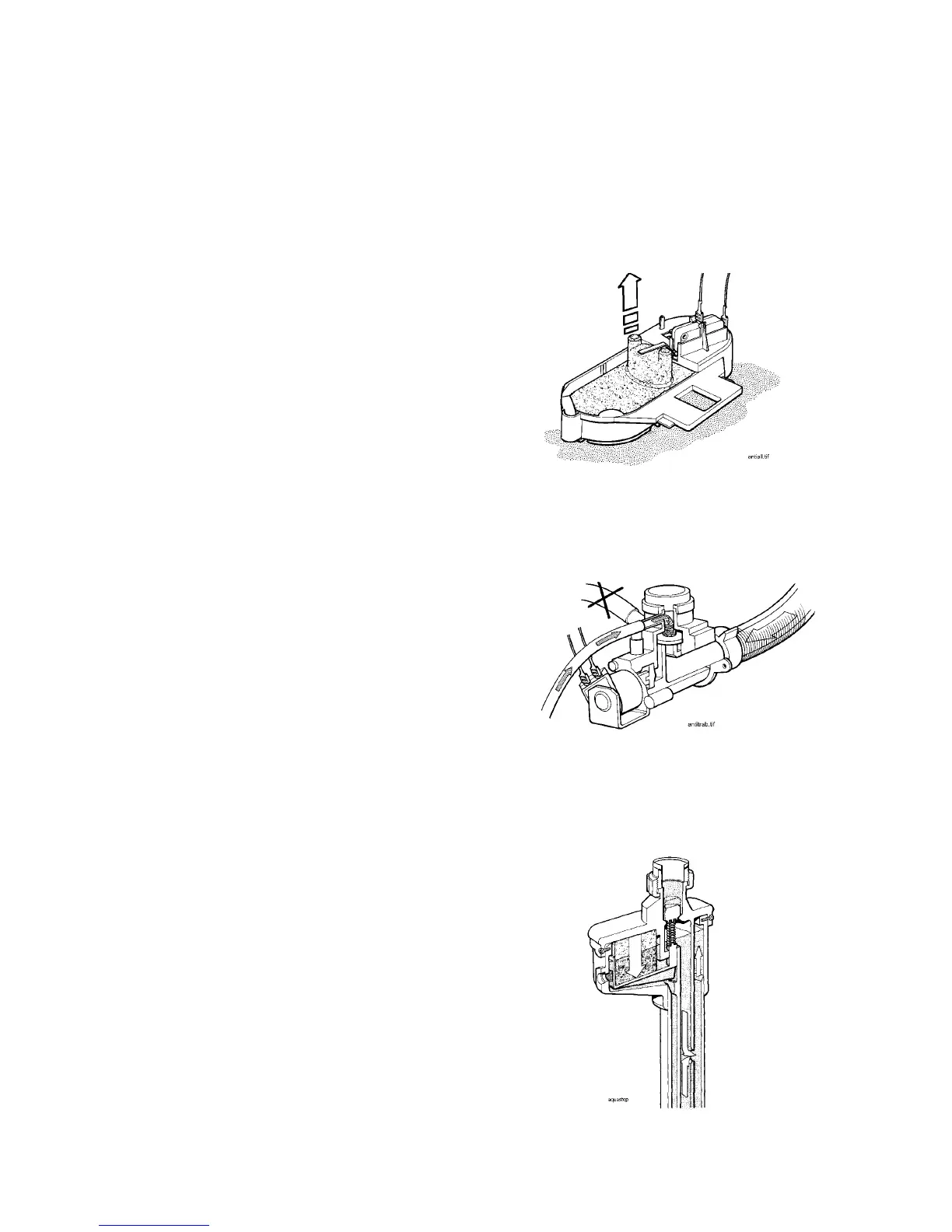

ANTI-FLOODING function

Electromechanical device connected in series to

the solenoid valve.

A floating sensor is housed in the bottom panel

of the machine. The sensor is connected to a

microswitch. When water is present in the

bottom of the tub, the float rises, actioning the

microswitch and disconnecting the solenoid

valve. As a result, the cycle is interrupted.

ANTI-OVERFLOW device

Mechanical device built into the solenoid valve

and connected with the IWMS.

As the level of water in the sump rises, the level

in the anti-overflow chamber of the IWMS, too,

rises, since the two sections are connected by a

tube.

When the water reaches the overflow level, it

flows through the siphon and descends to the

corresponding chamber in the IWMS. This

forces the internal air through the connector

tube, pressurizing the circuit, actioning the

safety device by moving the piston downwards

to block the flow of water.

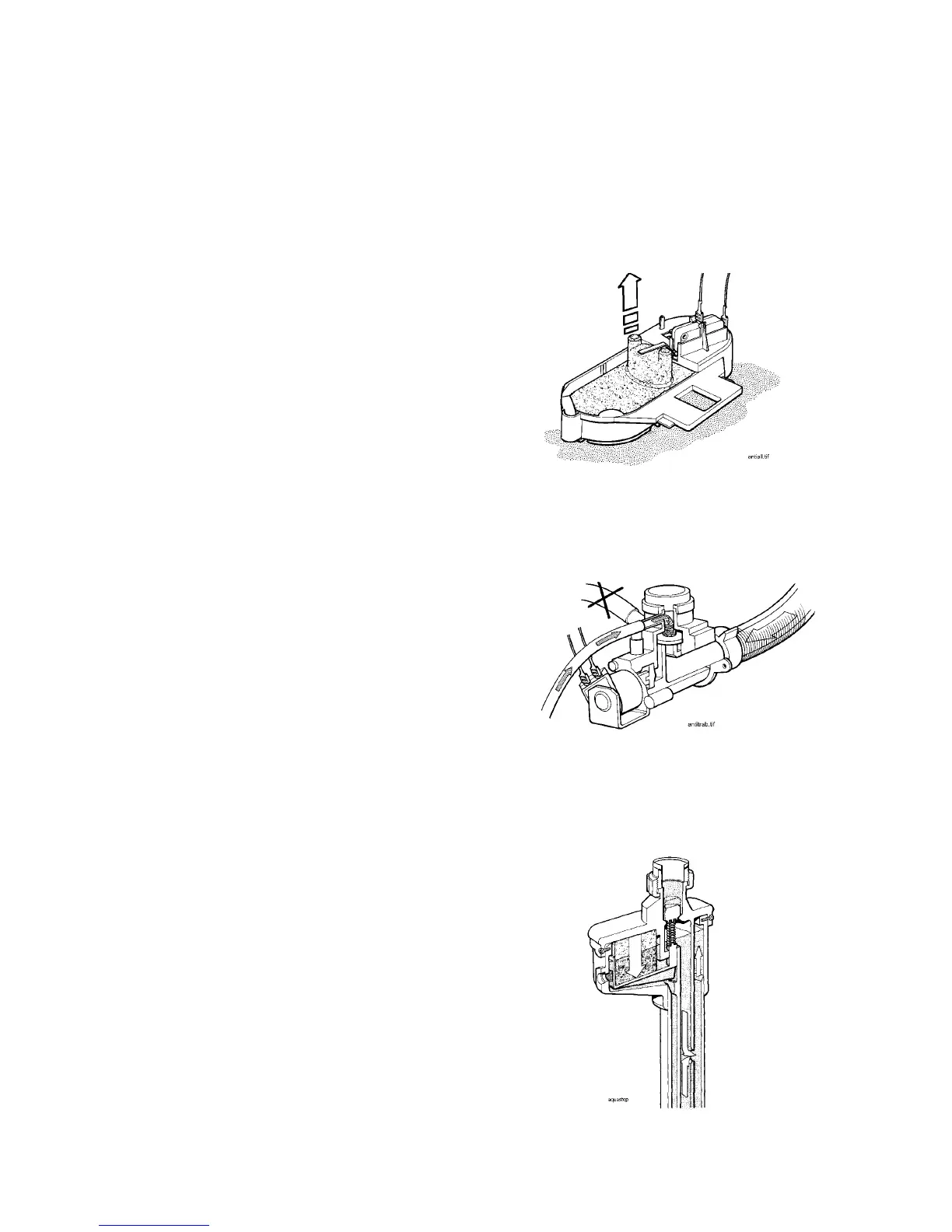

ACQUASTOP device

Mechanical device built into the drain hose.

This assembly consists of a fill hose at the

extremity of which the device itself is fitted. This

forms an integral assembly, since the two

sections are joined by a hermetic seal which

guarantees perfect water-tightness.

If a leak should occur or if the fill hose should be

damaged, the water is recovered and ducted

through the outer sheath to the inside of the

device. This actions the system, as the sensor

which comes into contact with the water

expends, forcing the valve downwards to block

off the flow of water completely.

25

Loading...

Loading...