76

2. Switching on

The soldering station can be switched on by means of the „Power”

switch. The processor then performs a segment test, i.e. all 108

segments are activated for approximately two seconds.

This is followed by the heat-up phase. The soldering iron heats up

until it reaches the set point temperature in effect just before the device

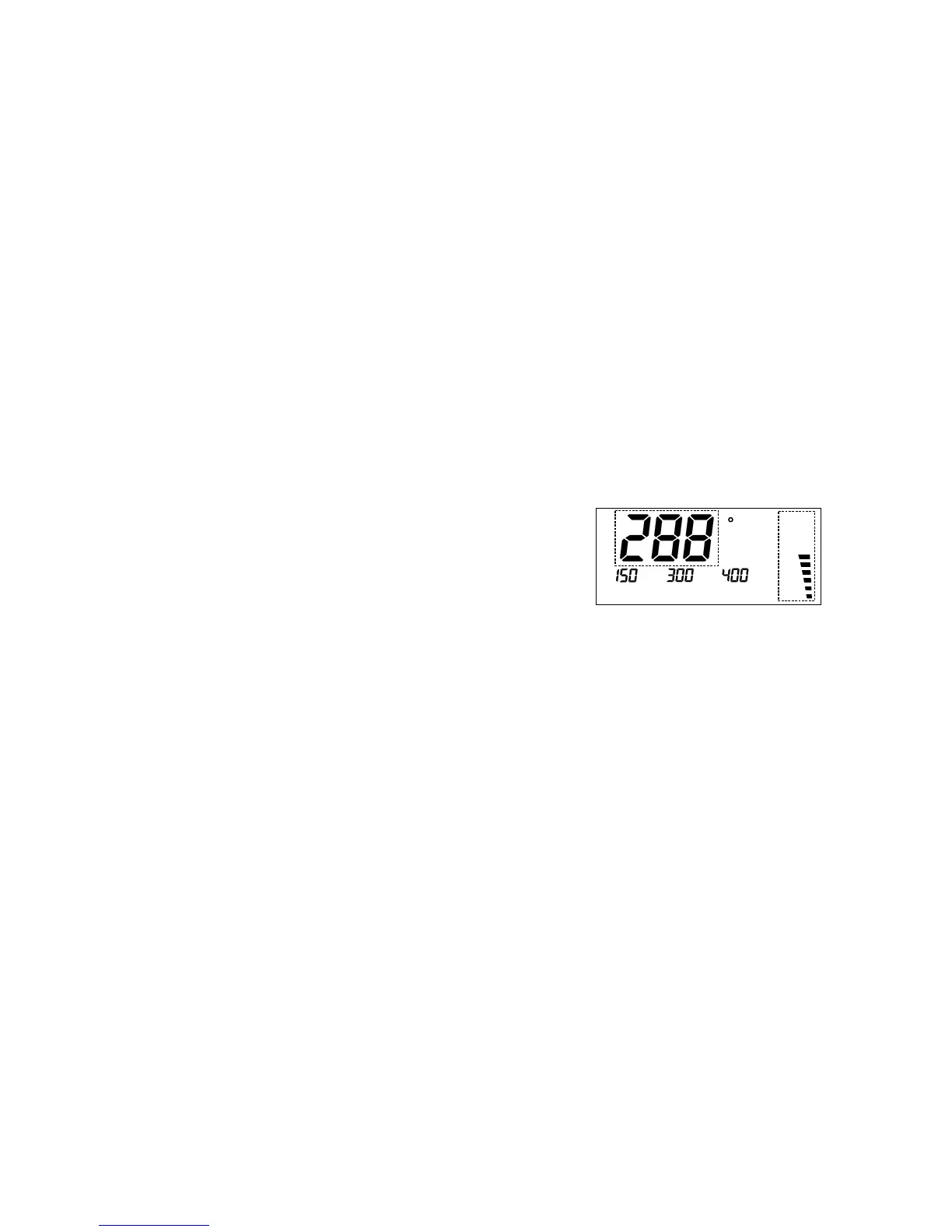

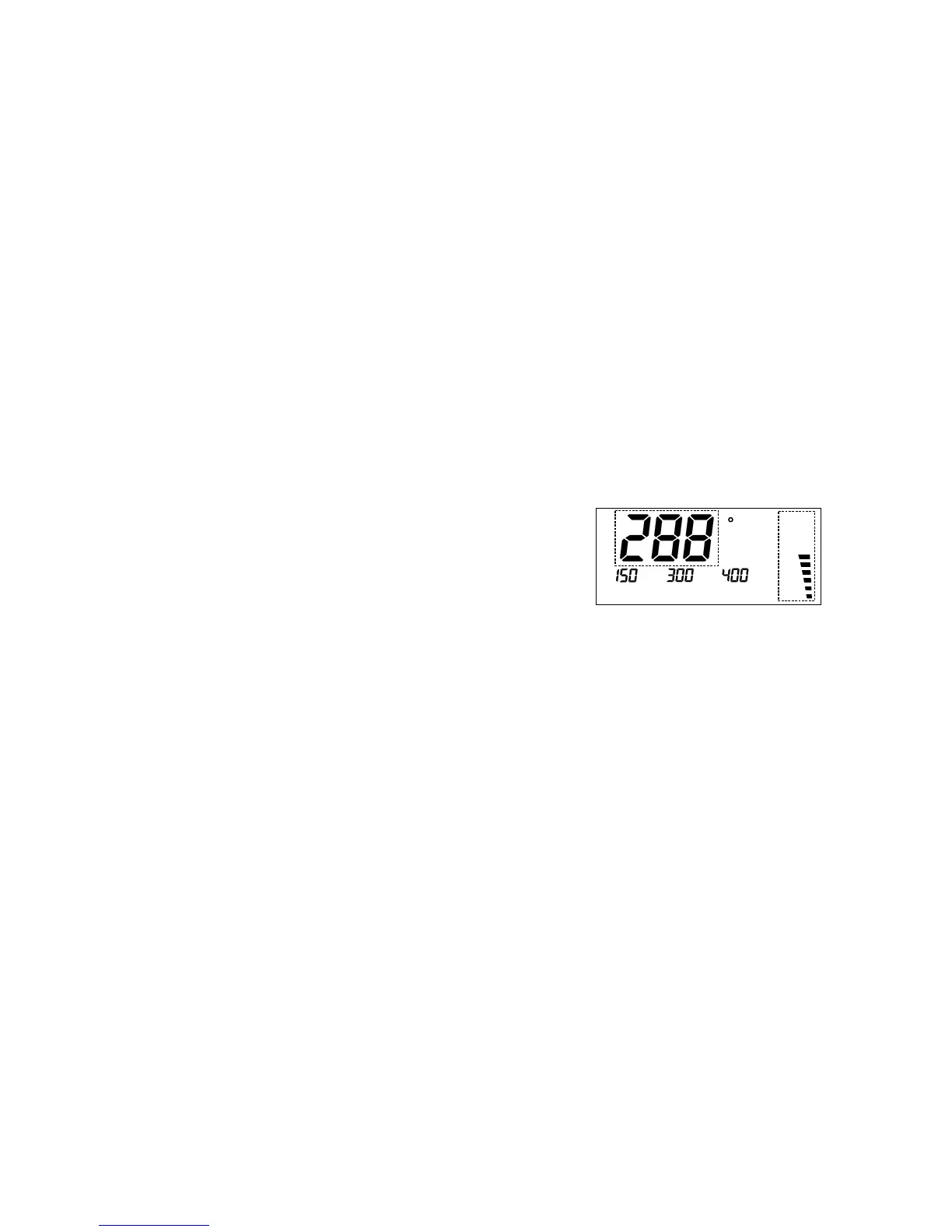

was switched off the last time. The LCD shows the current actual

temperature in the main display section and the „Power” bar-chart

(which can be disabled) indicates the heat being supplied to the

soldering iron; (see Figure 1). As soon as the set point temperature is

reached, the soldering iron is maintained constant at this temperature.

Figure 1

3. Adjusting the set point temperature with the „+” / „-” keys

The set point temperature can be adjusted inter alia by means of the

„+” and „-” keys.

As soon as one of these keys is pressed, the main display section

(see Figure 1) changes to show the set point temperature. This set

point temperature can then be jogged up or down in steps of 1° each

time the key in question is pressed. If the key is pressed and held

down, the set point temperature is incremented / decremented initially

in 1° steps for the first 10 digits and then subsequently in 10° steps. As

soon as the desired value is reached, the key must be released.

The main display section, after approximately three seconds, switches

back to showing the current actual temperature.

4. Selecting one of the programmed set point temperatures

The feature with the programmed set point temperatures provides real

soldering convenience. For different soldering jobs the most suitable

temperatures can be selected quickly and conveniently at the push of

standby and automatic power-off functions. The standby / automatic

power-off timer can be adjusted in 5-minute steps up to a maximum of

9 hours and 55 minutes. On expiry of this programmed timeout the

LS 50 automatically sets the preprogrammed standby temperature or

switches off completely. The standby mode can of course be activated

and deactivated at any time at the push of a button.

The soldering iron on the LS 50 operates with 48 W. It can thus heat

up to the desired working temperature very quickly and with plenty of

power in reserve. The processor determines the current actual

temperature via the integrated temperature sensor and regulates the

power of the soldering iron accordingly. As and when necessary a

new soldering tip can be attached very easily and quickly by simply

undoing the screw connector.

Brief Summary of Instructions for Use

1. Set up the device and insert the soldering iron plug in the DIN socket

on the station.

2. Switch on by means of the ,,Power” switch.

3. Adjust the set point temperature as desired by pressing the „+”/„-”

keys.

4. You can select one of the programmed set point temperatures by

pressing the appropriate „T1” /„T2”/„T3”key.

5. You can modify a programmed set point temperature by pressing

and holding down the appropriate „T1” / „T2”/ „T3” key and, while

doing so, adjusting by means of „+” or „-”.

Instructions for Use

In order to ensure that the device is used properly and as intended,

please be sure, before using the device, to read through these

Operating Instructions and Safety Instructions carefully and completely.

1. Setting up

First the device must be set up at your workplace and connected to a

mains socket. The plug from the soldering iron must then be inserted

in the DIN socket located on the front of the station. The solder sponge

must be laid in the stand and moistened.

Loading...

Loading...