Service Instructions

137462E Rev. D

August 2015

15

Section 3: Actuator Reassembly

Actuator Reassembly

3�3 Pneumatic Cylinder Reassembly

NOTE:

Review Section 3 steps 3.1.1 through 3.1.6 before proceeding with cylinder reassembly.

In section 3.3 where the step indicates to "lubricate, coat or apply lubricant", use lubricant

as identied in Section 1 step 1.6 for lubricating the part being installed.

3.3.1 Coat one O-ring seal (5-10) with lubricant and install onto outer diameter ange

located on cylinder/cylinder adapter end of housing (1-10).

3.3.2 Actuators equipped with cylinder adapter (4-15), models CBA830-SR, CBA930-SR

and CBA1030-SR (including M3/M3HW models), do steps 3.3.2.1 and 3.3.2.2.

3.3.2.1 Install cylinder adapter (4-15) onto housing ange, with the stepped

outer diameter, of cylinder adapter (4-15), facing away from housing

(1-10).

3.3.2.2 Install one o-seal (5-15) onto stepped diameter of cylinder adapter (4-

15).

3.3.3 Coat all areas of piston (4-50) with lubricant.

3.3.4 Coat rod bushing (5-50) with lubricant and install into the internal rod bushing

groove located in the head of piston (4-50).

3.3.5 Coat rod T-seal (5-25) with lubricant and install in the internal seal groove in the

head of piston (4-50).

3.3.6 Coat piston seal (5-40) with lubricant and install into outer diameter seal groove of

piston (4-50).

3.3.7 Coat piston bearing (5-45) with lubricant and install into outer diameter bearing

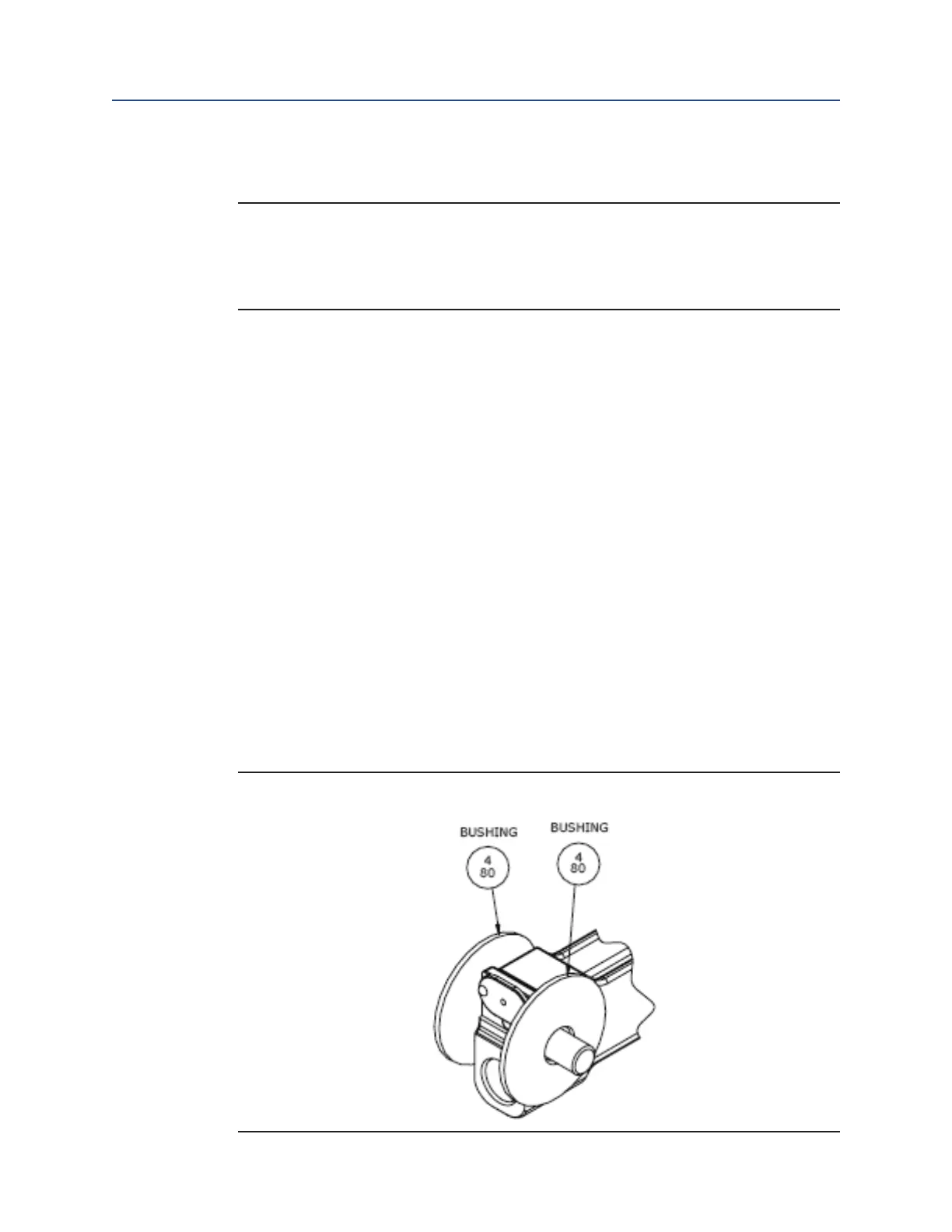

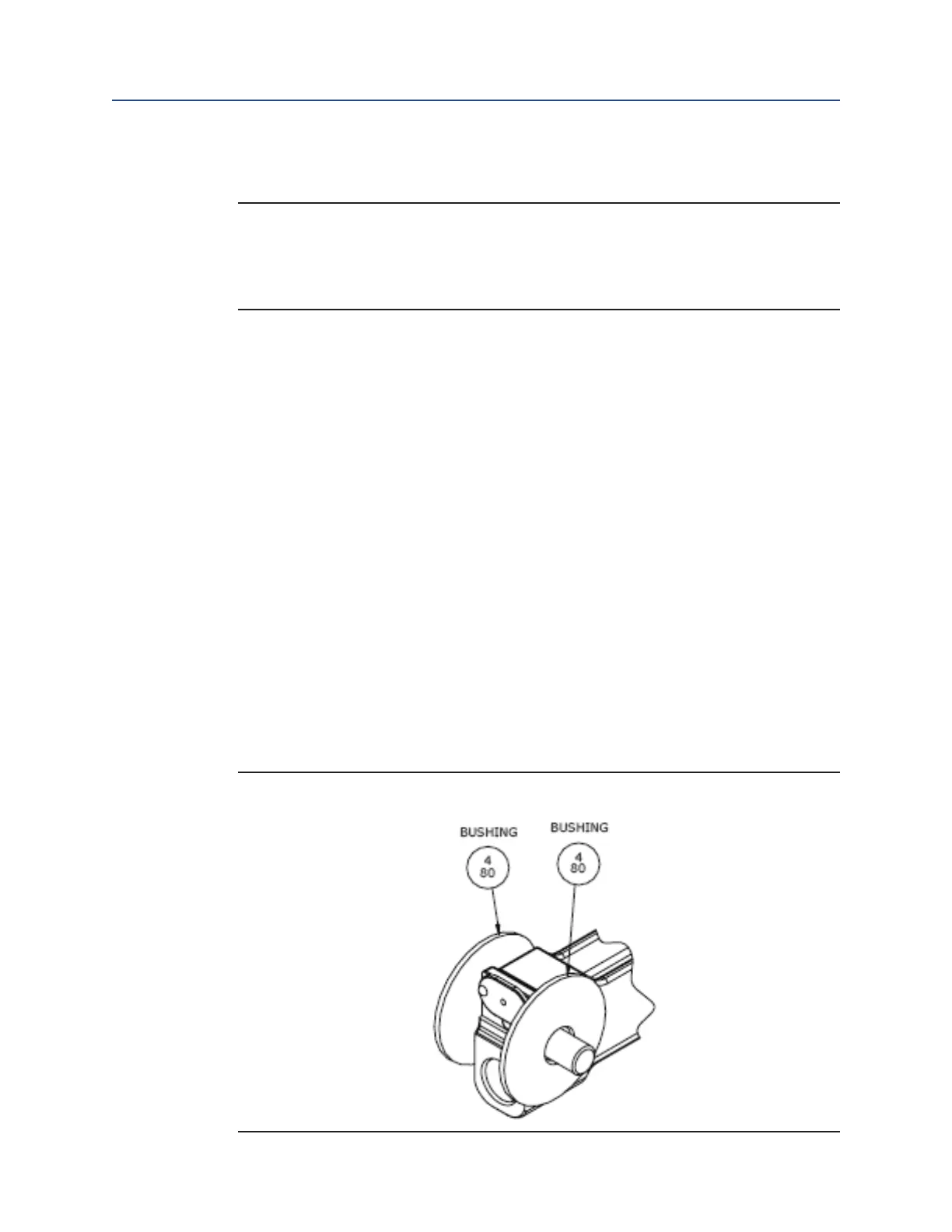

groove of piston (4-50).

3.3.8 Install two bushings (4-80) onto piston assembly (4-50) - Refer to following

drawing (Figure 1).

Figure 1 Bushing Installation

Loading...

Loading...