38

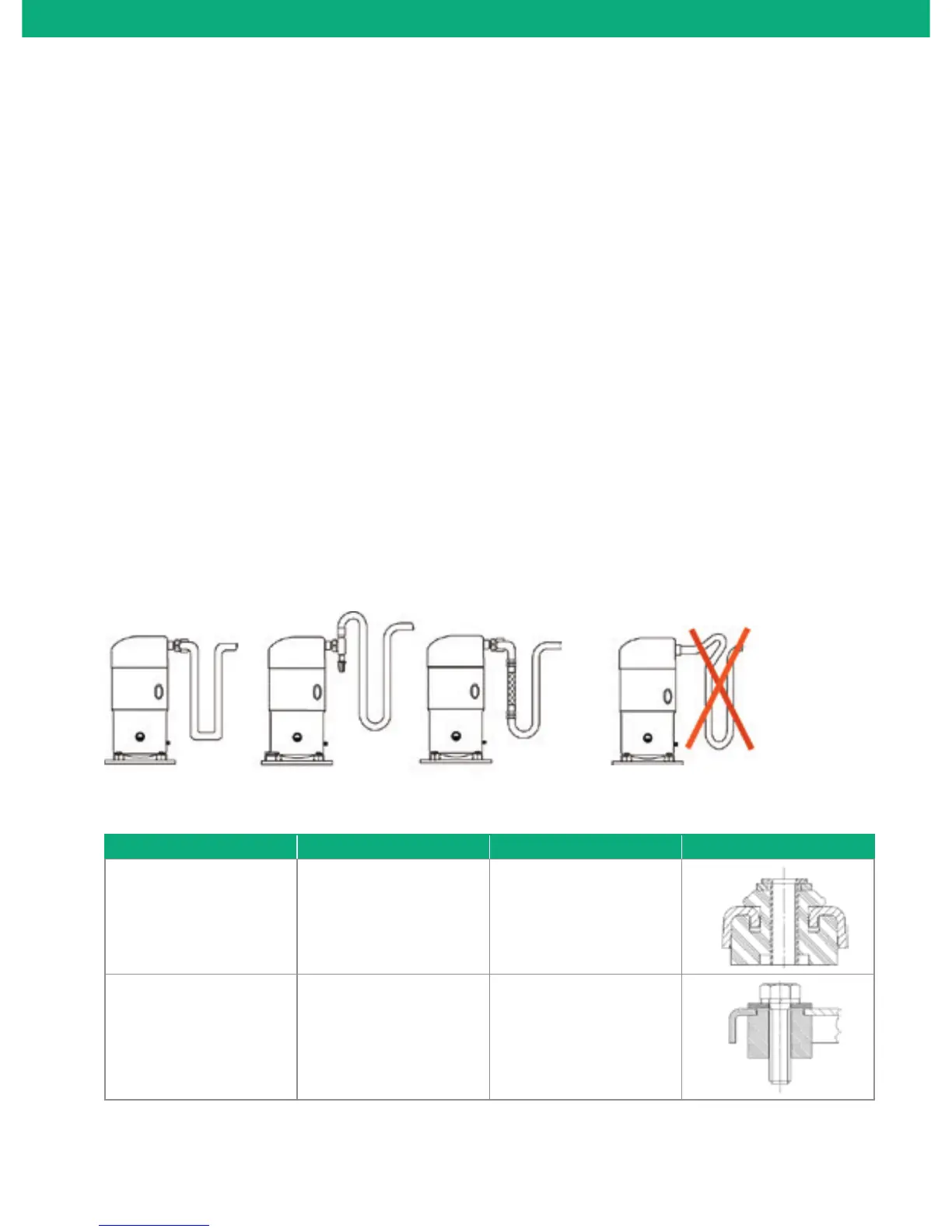

Figure 6: Tubing recommendation

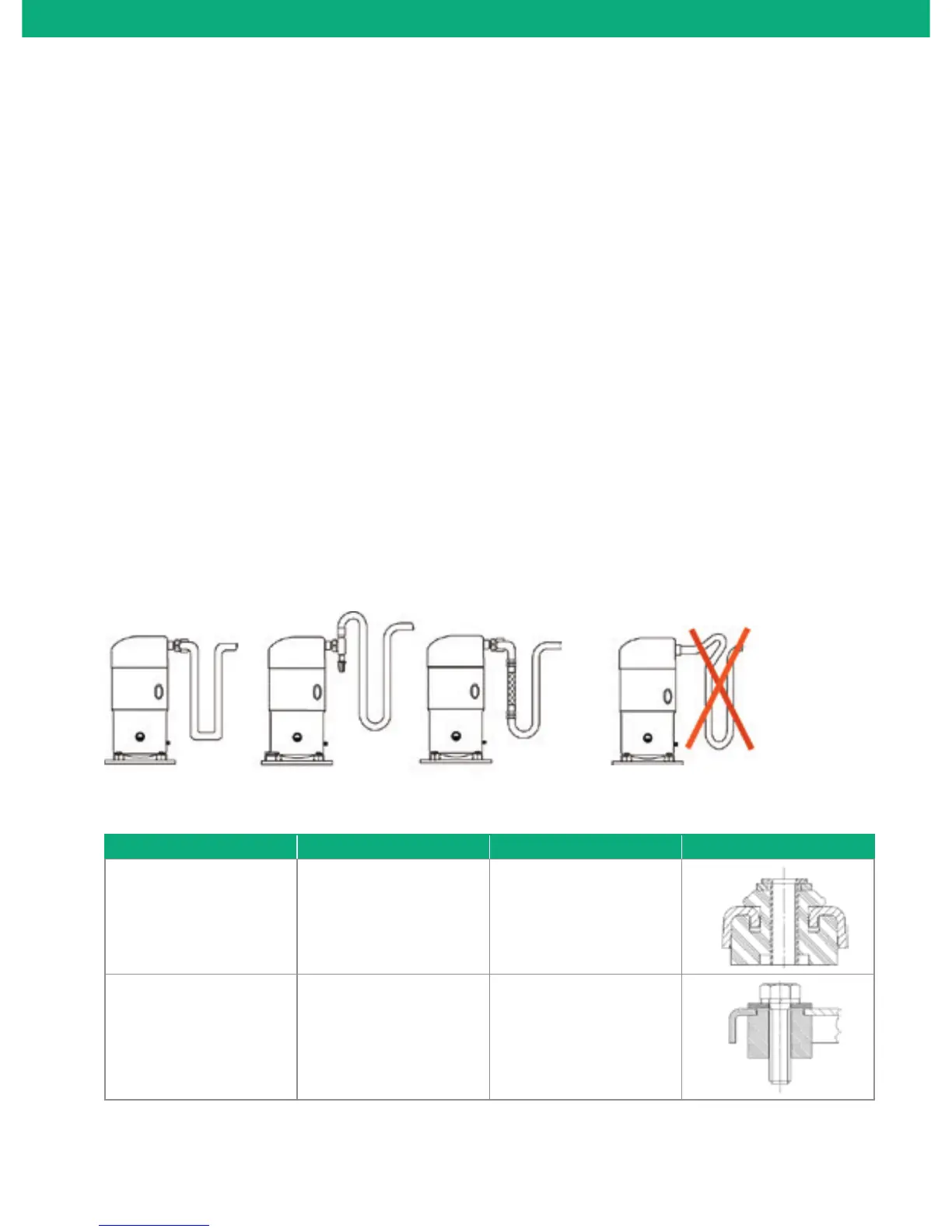

Compressors Ident Number Characteristics Drawing

ZB15K* to ZB45K*

ZF09K* to ZF18K*

ZF13KVE to ZF18KVE

ZS21K* to ZS45K*

8030450

527-0157-00

60-70

Durometer

ZB56K* to ZB11M*

ZF24K* to ZF48K*

ZF24KVE to ZF48KVE

ZS56K* to ZS11M*

8522911

527-0168-00

Variation = 8516741

Hard

steel

6. Tubing and mounting considerations

6.1 Starting pulse

The standard mount for the scroll compressor is a soft rubber mount. It is designed to transmit the lowest possible disturbance

to the mounting frame. Because of the flexibility of this mount, it is essential that tubing to each compressor be designed to

accommodate the movement which will occur, particularly upon start-up.

The three phase motors used in the refrigeration scroll compressors exhibit a high starting torque characteristic. The reaction of

the stator is directly on the shell because there are no internal spring mounts. This reaction causes easily observable movement of

the shell when the standard mounts are used and this is normal. However, if the suction and discharge tubing of the compressor is

closely clamped to the frame or linked to another compressor, the tubing will restrain the movement and the motor reaction force

will be taken by the tubing. This may cause excessive stress and premature failure of tubing joints.

6.2 Resonance

The discharge pulse can in some configurations give rise to resonance of tubing. It is advisable to avoid a natural frequency of

between 45 and 55 Hz for the section of tubing between the compressor and the rst clamp. It is often not possible to determine

this in advance but in the unlikely event of a resonance problem arising a change in tube conguration will usually resolve it.

6.3 Recommendations for tubing and mounting

Always allow some exibility in the tubing to the suction and discharge connections. If the standard mounts are used there should

be at least two bends and a vertical section before the tube joins a header. Test the nished assembly by rocking the compressor on

its mounts. Vibration eliminators may be used but are not essential if the tubing has sufcient exibility. Vibration eliminators should

be tted in the vertical plane.

An alternative harder mount as detailed in Figure 7 is recommended. This will allow more loads to be transmitted via the feet,

and the very small additional vibration transmission is not usually a problem in refrigeration applications. It is still advisable to

incorporate a vertical section of tube between the compressor and the rst rigid mount. This will give exibility and minimise the

risk of resonance.

Loading...

Loading...