13

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

AE5-1377 R2

Application Engineering

BULLETIN

*

Lockout feature can be reset by disconnecting the unit power source

and then reconnection of the unit power source.

88

(1second) ->

02

(3 seconds) ->

-F

(3 seconds) ->

00

02

= Software Version No.

-F

“F”- With OD Fan Speed Control; “-” = W/O OD Fan Speed Control

“L”- LT; “-” = MT

00

= Power On

Delay Firmware Unit Revision Stator

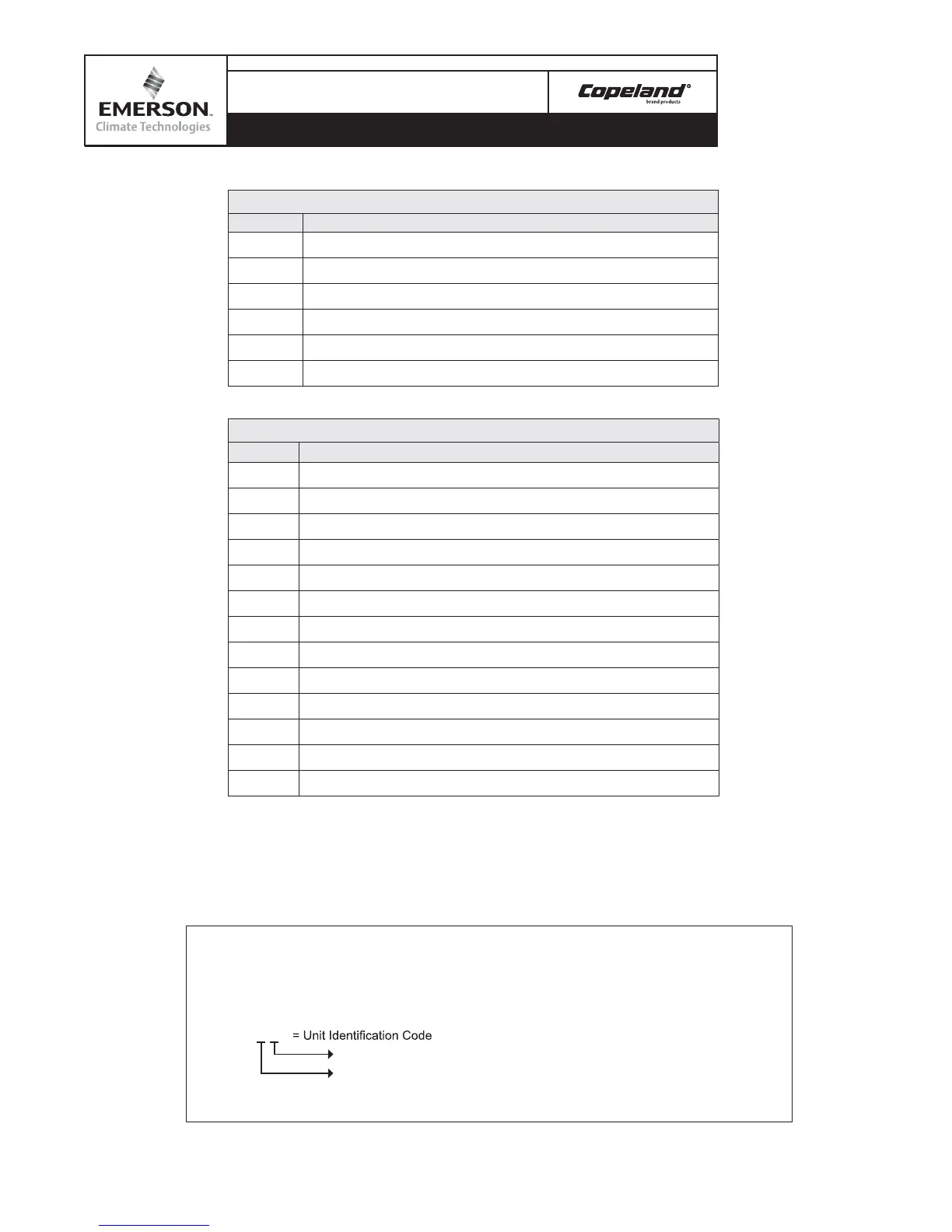

LED1 - Unit Status

Display Status

0

Idle (Stop When Reach To Set-point)

1

Run

2

About To Start

1

3

Defrost

4

Unit Trip

5

Unit Lockout

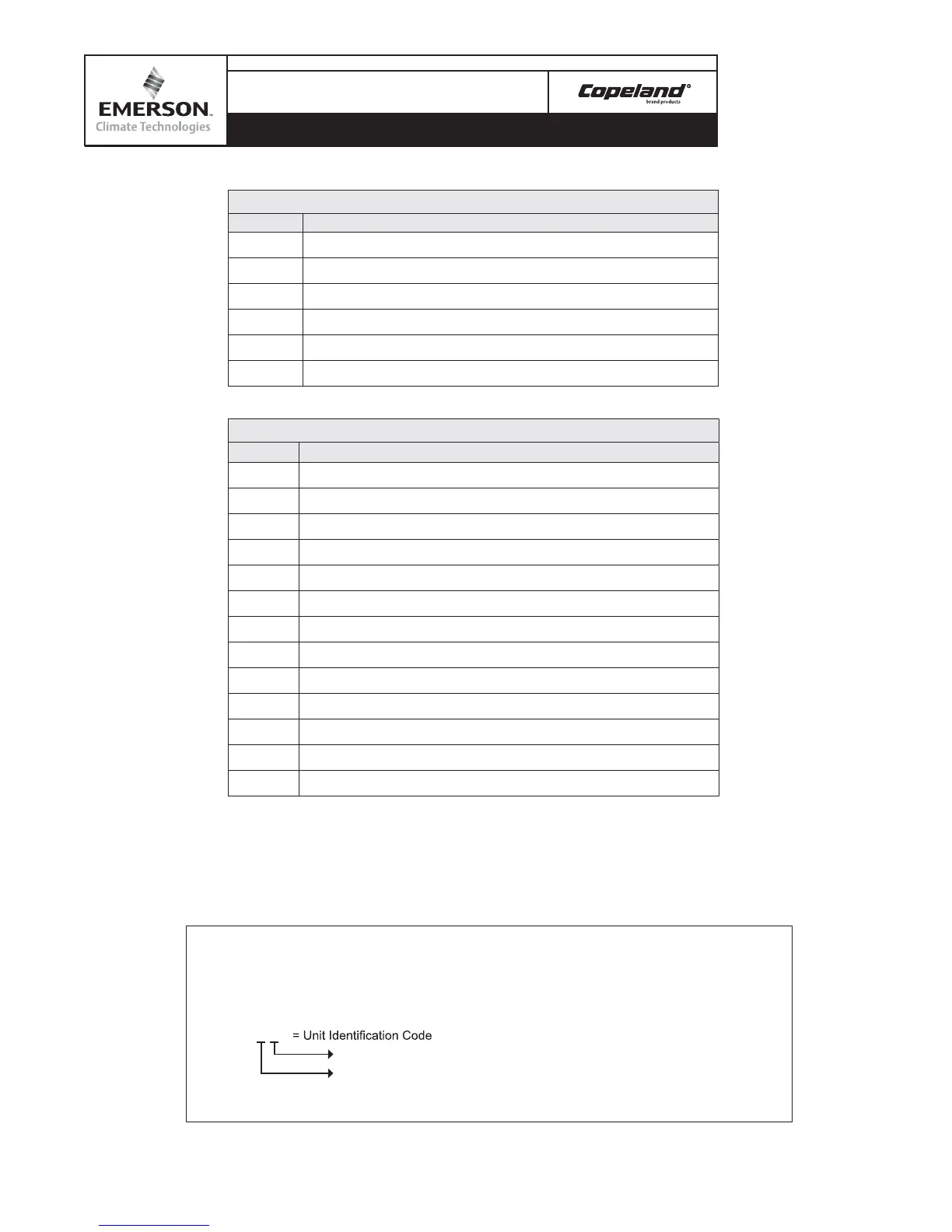

LED2 - Error/Warning Code

Display Error/Warning

0

No error/warnings

1

Compressor Phase Error (Wrong Phase Sequence/Loss Of Phase)

2

Compressor Inside Internal Motor Protector Trip

3

Compressor Over Current

4

Discharge Gas Overheat (High Discharge Temperature)

5

Compressor High Pressure Cut Out

6

Not Used

7

DLT Thermistors Failure

8

Ambient Temperature Sensor Failure

9

Mid-coil Temperature Sensor Failure

a

PHE Vapor In Temperature Sensor Failure or over range

2

C

PHE Vapor Out Temperature Sensor Failure or over range

2

e

System Liquid Flood Back Warning

Note:

1

This signal is for Fresh Start, Normal Start Program and any start request delay.

2

PHE Vapor In/Out Temperature Sensor is not applicable in XJAM condensing unit (MT units).

All error/warning messages are priority-ranked from highest to lowest.

If unit is initially powered on, the diagnosis module will show signal similar to the below example:

Table 6 – Diagnostics Module Display

Table 6a – Diagnostics Module Display

Diagnostics Module Start Up Information

Loading...

Loading...