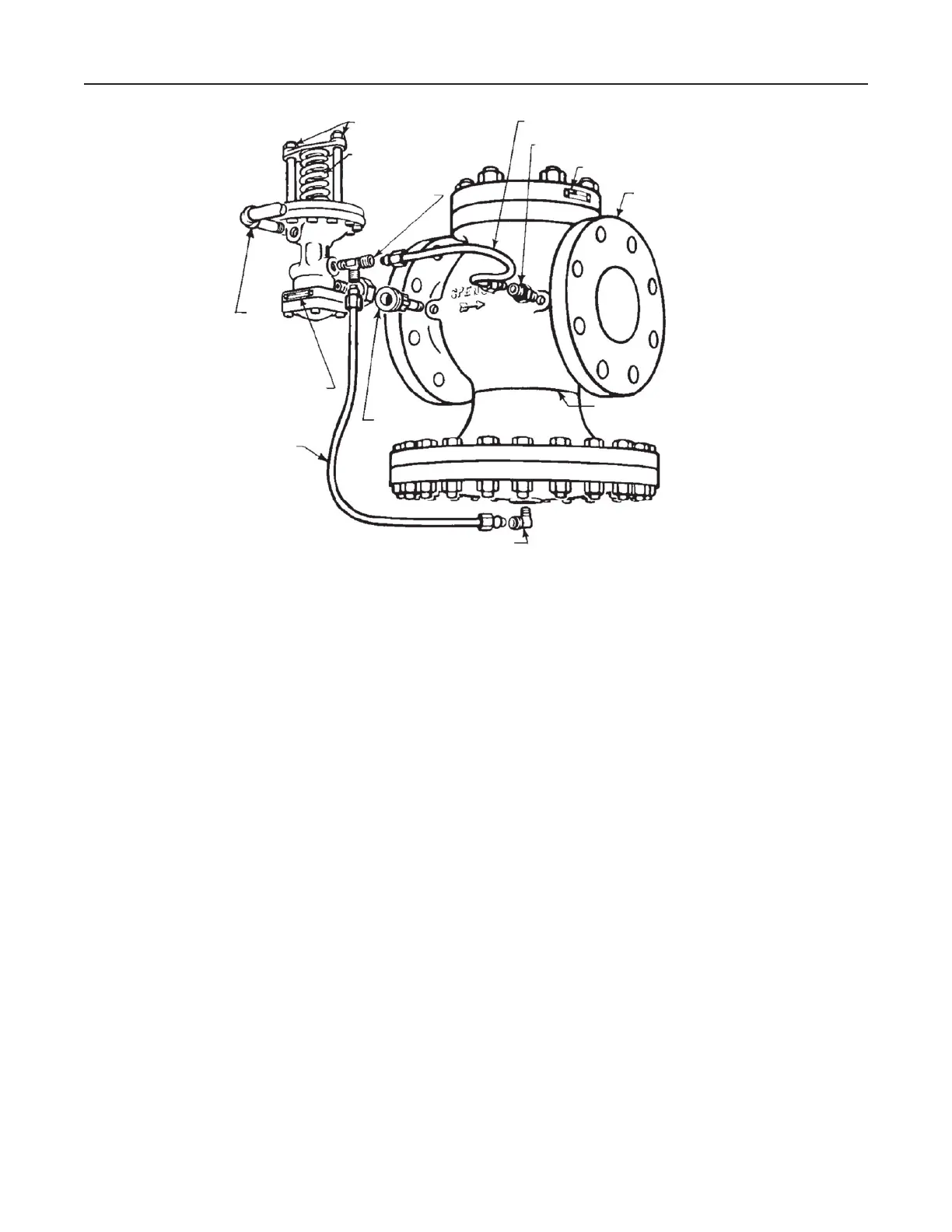

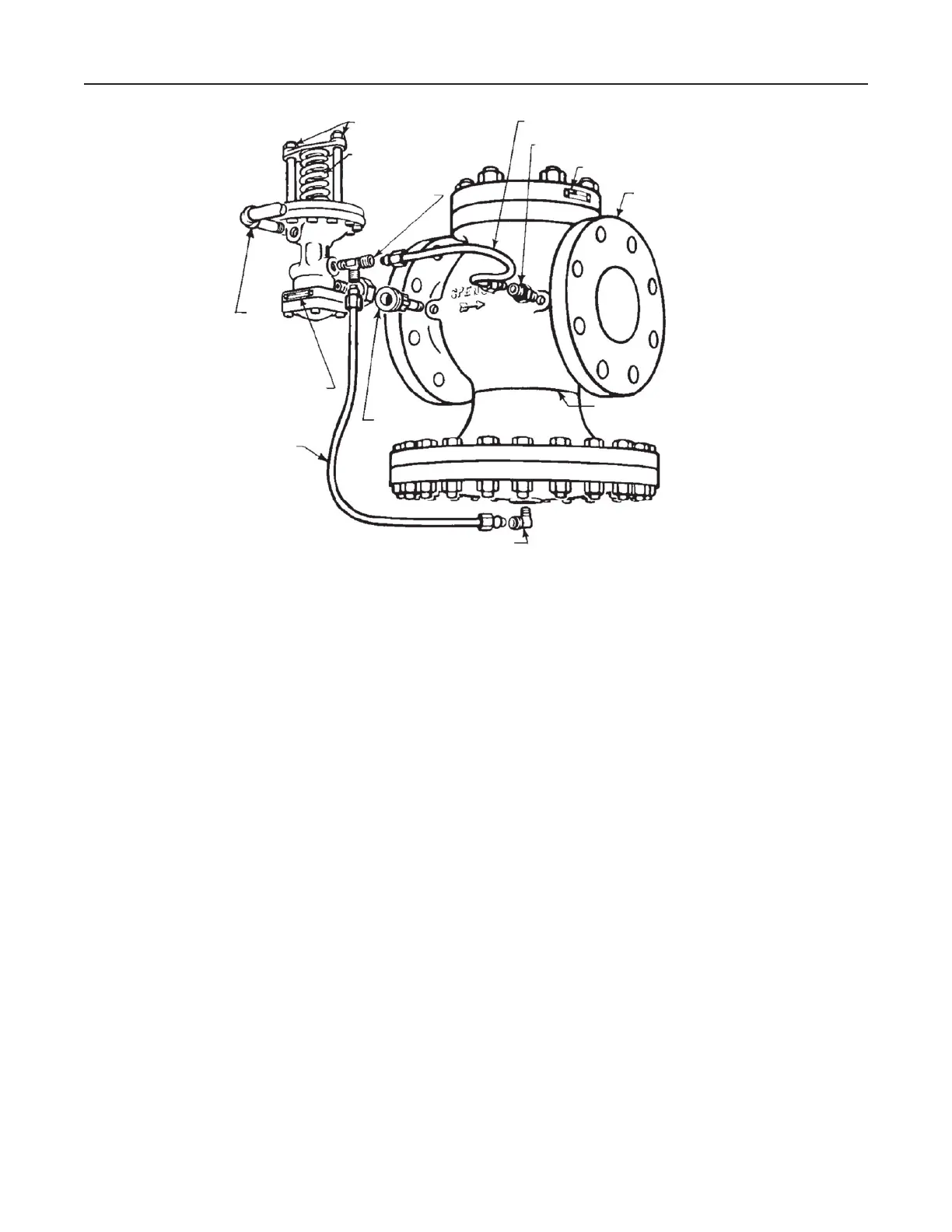

For Integral Mount Construction

1. Remove blind flange on pilot and mount on blind

flange of main valve using provided bolt.

2. Screw 4A bleed port fitting into the 1/8 in. pipe tap

at the outlet of the main valve body. Note bleed

orifice in this fitting is vital to operation of regulator.

3. Screw 8B tee into 1/8 in. pipe tap in pilot. Select

tap facing downstream.

4. Screw No. 5B elbow into 1/8 in. pipe tap on

underside of main valve diaphragm chamber.

5. Connect tubing bends as illustrated in Figure 3.

Figure 3. Mounting Pilot on Type E2 Main Valve

BLEEDPORT BEND

NO. 8B TEE

NO. 4A BLEEDPORT

NO. 5B OPEN ELBOW

RESTRICTION

BEND

ADJUSTING NUTS

ADJUSTING SPRING

SERIAL NO. PLATE

SERIAL NO. PLATE

1/4 IN.

CONTROL

PIPE

1/4 IN.

UNION

MAIN VALVE

TYPE E2

DO NOT INSULATE

BELOW THIS LINE

Control Pipe (Not required with

Type T14)

1. Use 1/4 in. pipe for this line which connect the

pilot diaphragm chamber to the desired point of

pressure control.

2. Take the control at a point of minimum turbulence.

Avoid control immediately at the valve outlet or

after a turn.

3. When the delivery pipe expands in size, select a

spot at least 4 pipe diameters beyond the point

of enlargement.

4. Pitch away from pilot to avoid erratic operation and

excessive fouling.

5. Eliminate water pockets.

6. Locate delivery pressure gage in control pipe to

show pressure actually reaching pilot diaphragm

5

Type E2

Loading...

Loading...