2. Orient valve in desired direction. Enardo

Models 860 and 861 require the pipe-away

connection ange to be properly oriented before

the base is bolted down.

3. After the valve has been properly aligned, install nuts

and bolts. Tighten the bolts down in a cross-hatched

pattern. Ensure the valve is securely fastened.

Installation

△

CAUTION

Ensure the tank is at atmospheric pressure

before opening. A pressure build-up inside

the tank can cause a spray to be emitted

from the valve if opened under pressure.

Springs are energy storage devices and

are dangerous if handled improperly.

Never loosen any nuts or cap screws

until all spring preload has been relieved.

Always use appropriate safety equipment

including safety glasses or shields any

time you are working with a spring-

loaded valve.

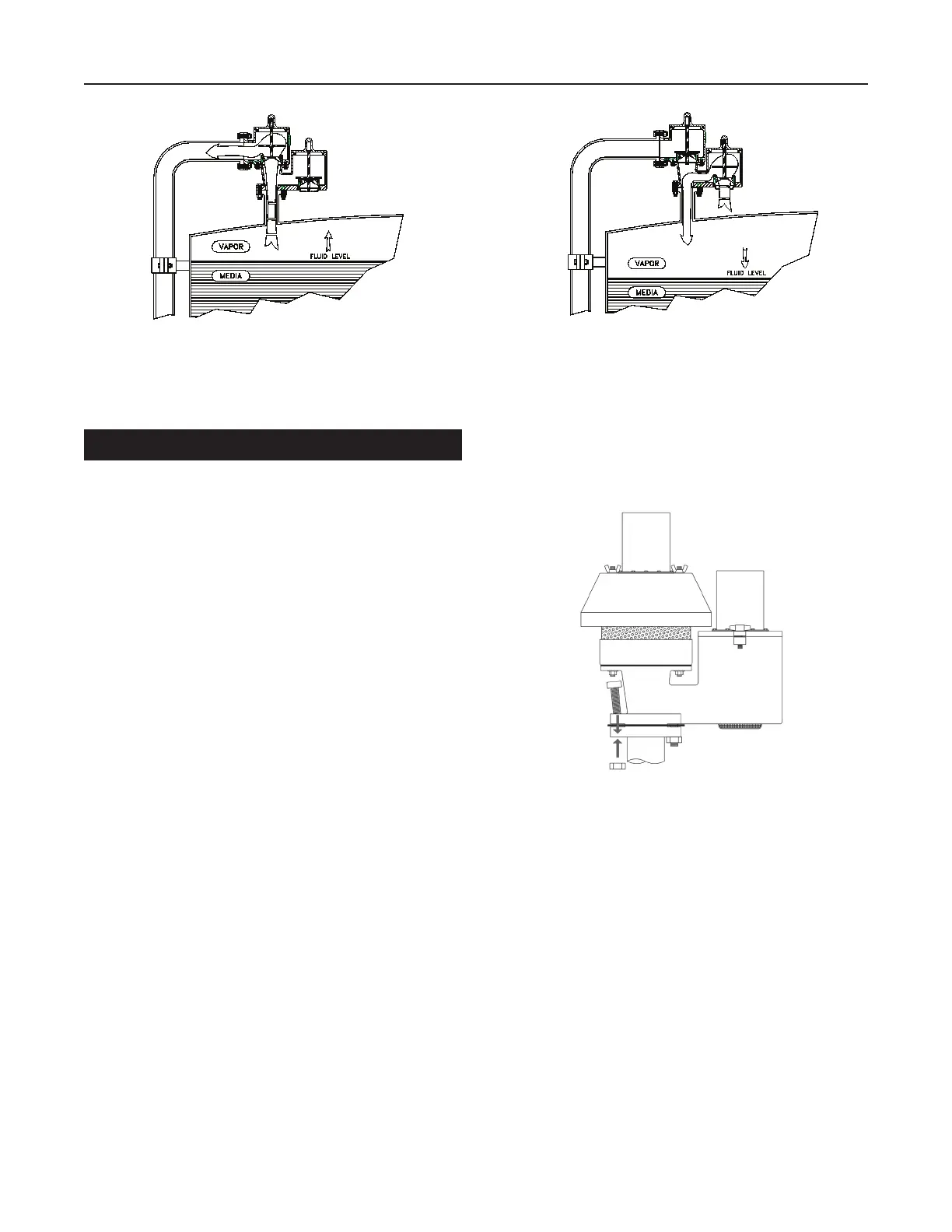

Installing Pressure/Vacuum Relief Valves

with Only Spring-Loaded Pallets

1. Attach the valve to the appropriate mating ange

using a proper gasket. To ensure proper function,

install the valves to a level horizontal surface

so the pallet will move vertically. For Enardo

Models 860, 960 and 962, the valve shipped from

factory has certain studs installed.

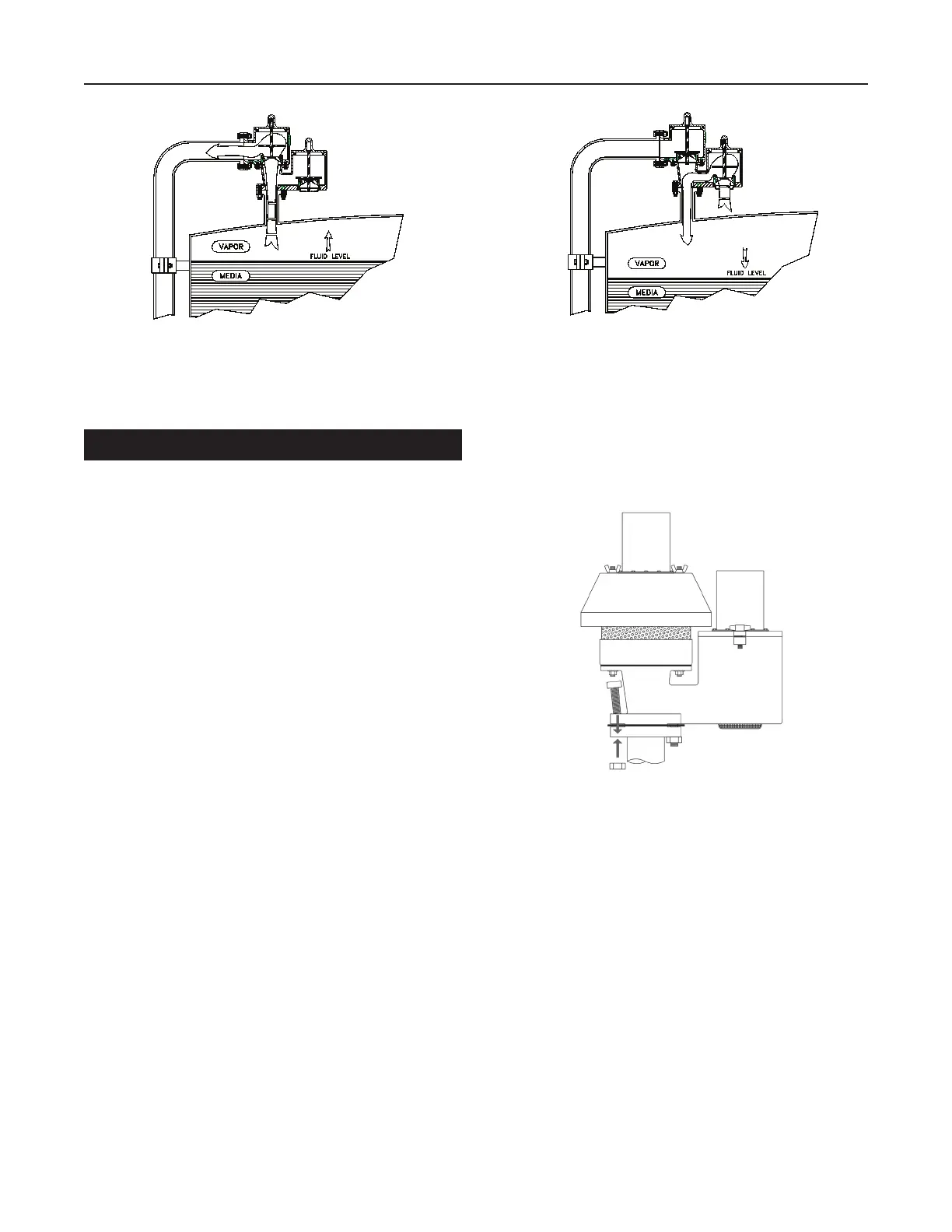

Figure 6. Pressure and Vacuum Flow

PRESSURE FLOW VACUUM FLOW

5

Enardo 860 and 960 Series

Outside North America Only

Loading...

Loading...