Operating instruction

EXD-HP1/2 Controller with ModBus

communication capability

Emerson Climate Technologies GmbH www.climate.emerson.com/en-gb Date: 17.12.2020

Am Borsigturm 31 I 13507 Berlin I Germany EXD-HP12_OI_EN_DE_RU_1220_R06_865921.docx

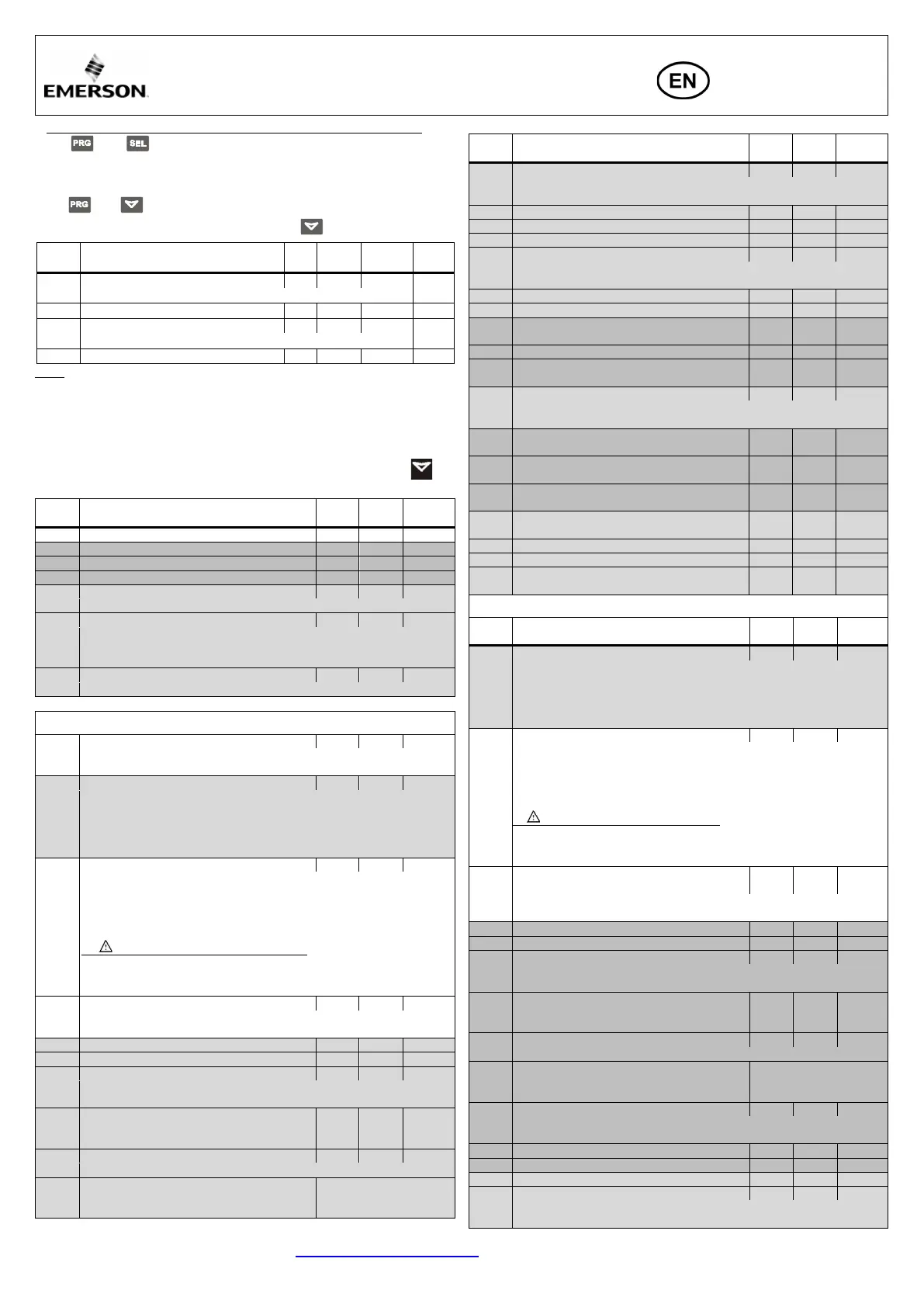

Manual alarm reset/clearing functional alarms (except hardware errors):

Press and together for 5 seconds. When the clearing is done, “CL”

message appears for 2 seconds.

Manual mode operation

Press and together for 5 seconds to access to manual mode operation.

List of parameters in scrolling sequence by pressing button

Code

Parameter description and choices

Min Max

Manual mode operation; circuit 1

Manual mode operation; circuit 2

Note: During manual operation, functional alarms such as low superheat are

disabled. It is recommended to monitor the system operation when the controller

is operated manually. Manual operation is intended for service or temporary

operation of valve at a specific condition. After achieving the required operation,

set the parameter 1Ho and 2Ho at 0 so the controller automatically operates the

valve(s) according to its setpoint(s).

List of parameters in scrolling sequence by pressing

button:

Code Parameter description and choices Min Max

Circuit 2 of EXD-HP2 enabled

0 = Enabled; 1 = Disabled

0 = °C, K, bar; 1 = F, psig

This Parameter effects only the display. Internally the units are allways SI-

0 = No display 1 = Circuit 1 2 = Circuit 2 (only EXD-HP2)

Parameters Circuit 1

0 = Superheat control

1 = Economizer control (Only for R410A/R407C/R32)

0 = Standard control coil heat exchanger

1 = Slow control coil heat exchanger

2 = fixed PID

3 = fast control plate heat exchanger (not for 1uE = 1)

4 = Standard plate heat exchanger (not for 1uE = 1)

0 = R22 1 = R134a 2 = R410A 3 = R32 4 = R407C

5 = R290* 6 = R448A 7 = R449A 8 = R452A 9 = R454A*

10 = R454B* 11 = R454C* 12 = R513A 13 = R452B* 14 = R1234ze*

15 = R1234yf *

*) EXN not permitted

*) Warning -Flammable refrigerants: EXD-HP1/2

has a potential

ignition source and does not comply with ATEX requirements. Installation

only in non-explosive environment. For flammable refrigerants only u

se

valves and accessories approved for it!

Installed pressure sensor type

0 = PT5N-07… 1 = PT5N-18…

2 = PT5N-30… 3 = PT5N-10P-FLR

Start opening duration (second)

Low superheat alarm function

0 = disable (for flooded evaporator) 1 = enable auto reset

2 = enable manual reset

If 1uL = 1 or 2 (enabled auto or manual reset)

3

30

6

MOP set-point (°C) saturation temperature

Factory setting according to selected refrigerant

(1u0). The default value can be changed

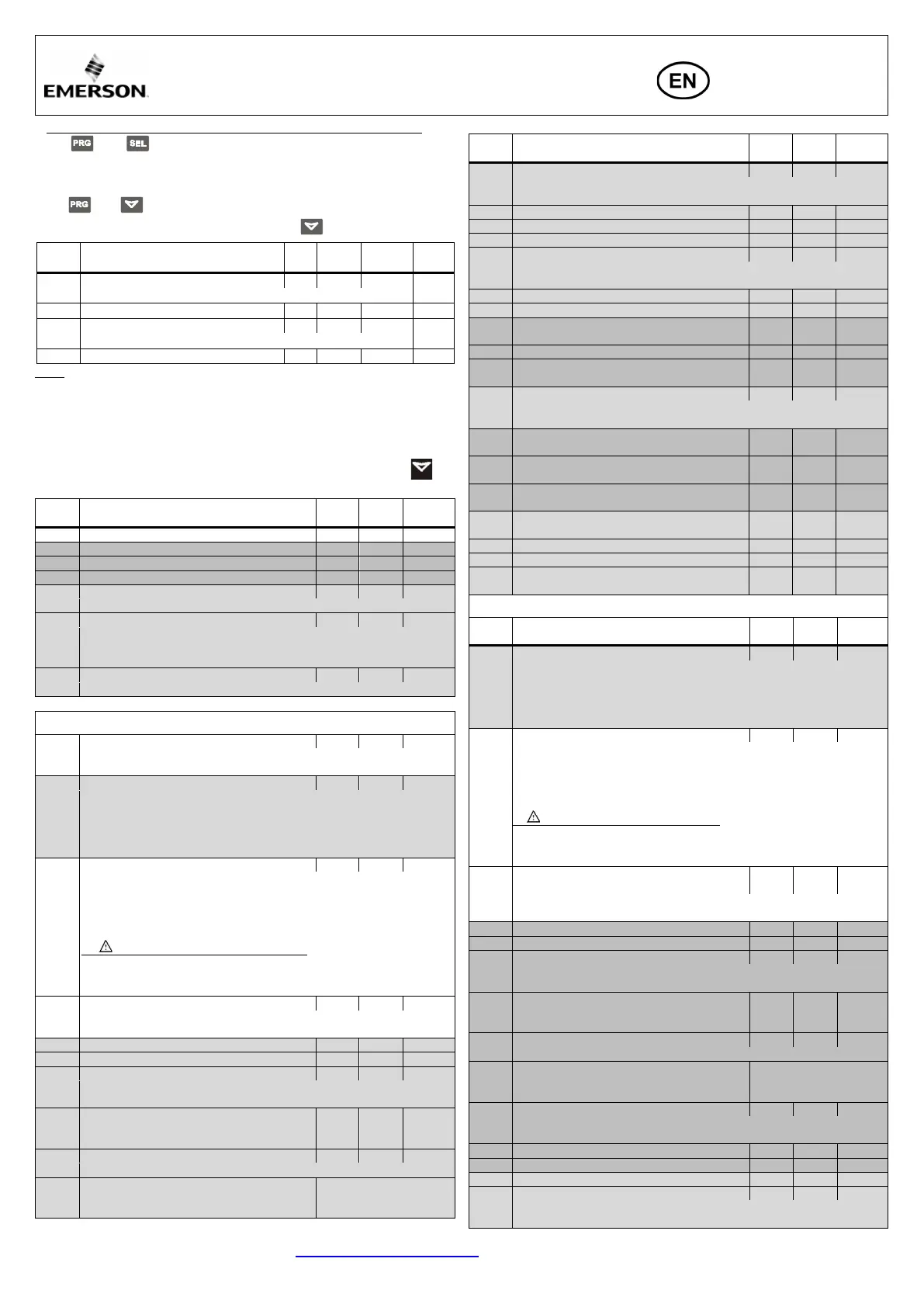

Code Parameter description and choices Min Max

Low pressure alarm mode circuit 1

0 = disabled 1 = enabled auto reset

2 = enabled manual reset

Low pressure alarm cut-out circuit 1

Low pressure alarm delay circuit 1

Low pressure alarm cut-in circuit 1

Freeze protection alarm function

0 = disabled, 1 = enabled auto-reset,

2 = enabled manual reset

Freeze alarm cut-out circuit 1

Freeze protection alarm delay, sec.

Superheat control circuit 1 fixed PID (Kp factor)

Display 1/10K

Superheat control circuit 1 fixed PID (Ti factor)

Superheat control circuit 1 fixed PID (Td factor)

Display 1/10K

Hotgas temperature sensor source

0 = ECP-P30

1 = Via Modbus input

Economizer control circuit 1 fixed PID

(Kp factor) Display 1/10K

Economizer control circuit 1 fixed PID

(Ti factor)

Economizer control circuit 1 fixed PID

(Td factor) Display 1/10K

1uH

High superheat alarm mode circuit 1

0 = diabled 1 = enabled auto-reset

0 1 0

High superheat alarm setpoint circuit 1

High superheat alarm delay circuit 1

1E2

Positive correction of measured Hotgas

temperature.

0 10 0

Parameters Circuit 2 (only EXD

-HP2)

Code Parameter description and choices Min Max

0 = Standard control coil heat exchanger

1 = Slow

control coil heat exchanger

3 = fast control plate heat exchanger

4 = Standard plate heat exchanger

0 = R22 1 = R134a 2 = R410A 3 = R32 4 = R407C

5 = R290* 6 = R448A 7 = R449A 8 = R452A 9 = R454A*

11 = R454C* 12 = R513A 13 = R452B* 14 = R1234ze*

Warning -Flammable refrigerants: EXD-HP1/2 has a potential

ignition source and does not comply with ATEX requirements. Installa

tion

-explosive environment. For flammable refrigerants only use

valves and accessories approved for it!

Installed pressure sensor type

(When DI2 is off)

0 = PT5N-07… 1 = PT5N-18…

2 = PT5N-30… 3 = PT5N-10P-FLR

Start opening duration (second)

Low superheat alarm function

0 = disable (for flooded evaporator) 1 = enable auto reset

2 = enable manual reset

Superheat set-point (K)

If 2uL = 1 or 2

(enabled auto or manual reset)

3

30

6

MOP set-point (°C) saturation temperature

Factory setting according to selected refrigerant

(2u0). The default value can be changed

2P9

Low pressure alarm mode circuit 2

0 = disabled 1 = enabled auto reset

2 = enabled manual reset

Low pressure alarm cut-out (bar) circuit 2

Low pressure alarm delay (sec) circuit 2

Low pressure alarm cut-in (bar) circuit 2

Freeze protection alarm function

0 = disable, 1 = enable auto-reset,

2 = enable manual reset

Loading...

Loading...