Operating instruction

EXD-HP1/2 Controller with ModBus

communication capability

Emerson Climate Technologies GmbH www.climate.emerson.com/en-gb Date: 17.12.2020

Am Borsigturm 31 I 13507 Berlin I Germany EXD-HP12_OI_EN_DE_RU_1220_R06_865921.docx

Code Parameter description and choices Min Max

Freeze alarm cut-out circuit 2

Freeze protection alarm delay, sec.

Superheat control circuit 2

(Kp factor), fixed PID Display 1/10K

Superheat control circuit 2 (Ti factor),

fixed PID

Superheat control circuit 2 (Td factor),

fixed PID - Display 1/10K

2uH

High superheat alarm mode circuit 2

0 = diabled 1 = enabled auto-reset

High superheat alarm setpoint (K) circuit 2

High superheat alarm delay (Min) circuit 2

Selection for both circuits and discharge tempearature control

Code Parameter description and choices Min Max

Note: EXD-HP2 can drive two similar valves i.e. both valves must be

either EXM/EXL or EXN.

Discharge Temperature Setpoint

Start Setpoint

Discharge Temperature Control band

Discharge Temperature limit

MOP table (°C)

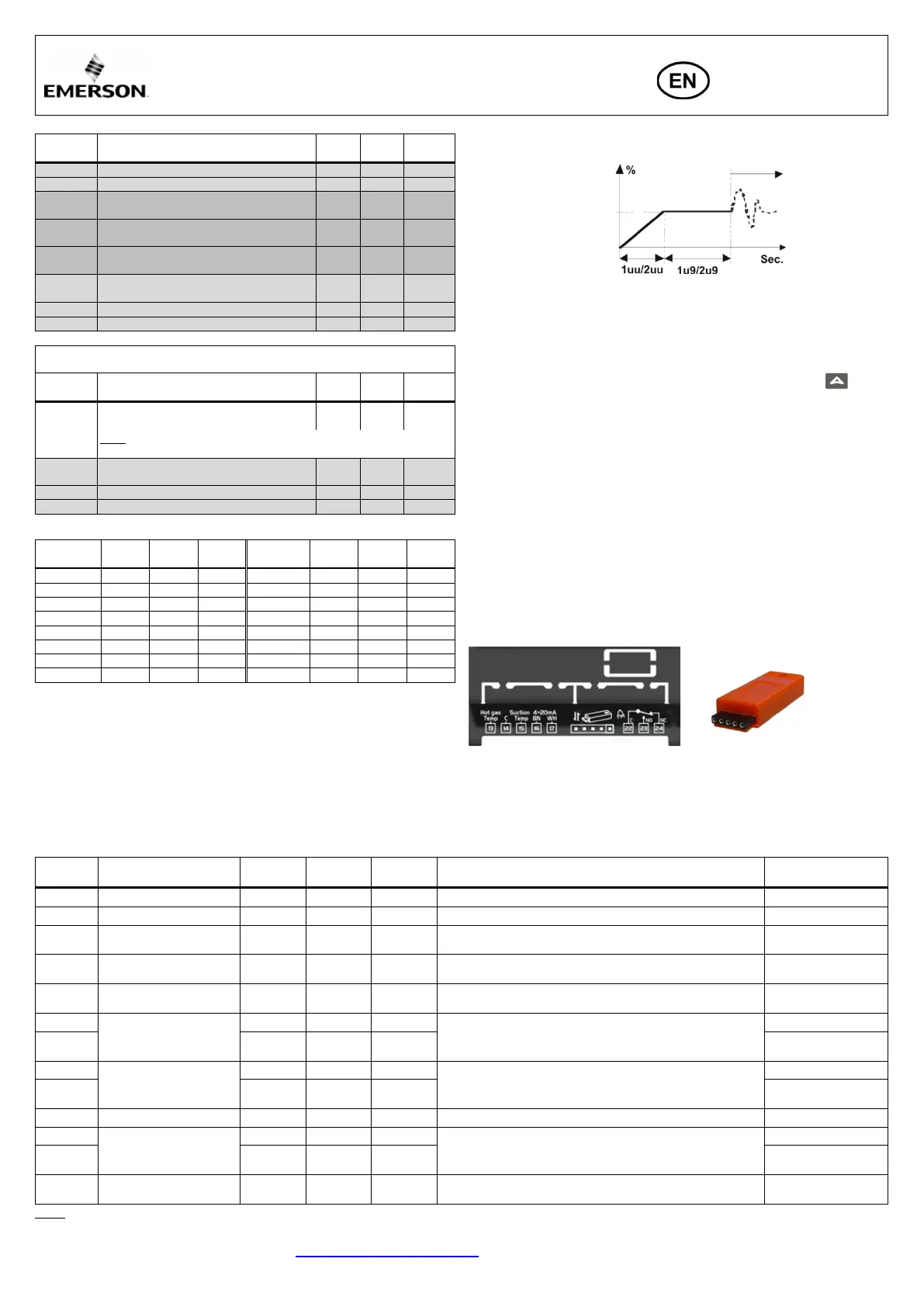

Control (valve) start- up behavior:

(Parameter 1uu/2uu and 1u9/2u9)

1uu/2uu:

Min.: 10% (<1 sec.)

Default: 20% (< 1.5 sec.)

Max.: 100% (< 6 sec.)

Upload/download Key: Function

• For serial production of systems/units, upload/download key allows the

transmission of configured parameters among range of identical systems.

Uploading procedure:

(storing configured parameters in key)

• Insert the key while the first (reference) controller is ON and press button;

the “uPL” message appears followed by “End” message for 5 seconds.

• Note: If the “Err” message is displayed for failed programming, repeat the above

procedure.

Downloading procedure:

(configured parameters from key to other controllers)

• Turn off power to new controller

• Insert a loaded Key (with stored data from reference controller) into new controller

and turn on the power supply.

• The stored parameters of the key will be downloaded automatically into the new

controller memory; The “doL” message appears followed by a “End” message for

5 seconds.

• The new controller with new loaded parameters setting will start to operate after

“End” message disappears.

• Remove the key.

• Note: If the “Err” message is displayed for failed programming, repeat the above

procedure.

Error/Alarm handling

Description

Valve What to do?

Requires manual reset

after resolving alarm

Pressure sensor 1/2 error

Check wiring connection and measure the signal 4 to 20 mA

Temperature sensor 1/2 error

Check wiring connection and measure the resistance of sensor

1Ed

Discharge hot gas

temperature sensor 3 error

- Triggered Operating Check wiring connection and measure the resistance of sensor No

1Π-/2Π-

EXM/EXL or EXN

electrical connection error

- Triggered - Check wiring connection and measure the resistance of winding No

1Ad

Discharge hot gas

temperature above limit

Triggered Operating

Check valve opening/ check liquid flow for flash gas free/check

discharge hot gas temperature sensor

No

Freeze protection

Check the system for cause of low pressure such as insufficient

load on evaporator

1P4/2P4: 2 Triggered Fully close Yes

Low superheat

(<0,5K)

Check wiring connection and operation of valve

1uL/2uL: 2

Triggered Fully close Yes

Low pressure

Check the system for cause of low pressure such as refrigerant

loss

1P9/2P9: 2 Triggered Operating Yes

Err

Failed

uploading/downloading

- - - Repeat again the procedure for uploading/downloading No

Note: When multiple alarms occur, the highest priority alarm is displayed until being cleared, then the next highest alarm is displayed until all alarms are cleared. Only then will

parameters be shown again.

Loading...

Loading...