DO Function Block

March 2006

5-149

considered a logic 1. With this option disabled, OUT_D

[9] is a direct copy of SP_D [8]. The readback value is

processed through the Invert option to become PV_D

[7]. The Use PV for BKCAL_OUT option specifies that

BKCAL _OUT equal the value of the process variable

(PV_D [7]) instead of the set point (SP_D [8]). If you

do not enable this option, BKCAL_OUT will equal

SP_D [8].

Output Block PV Status

The Output Block PV Status is determined by the

enabled status of the Resource Block parameter

FEATURE_SEL [18], the Transducer Block mode, and

enabled Active PlantWeb alarms. Refer to table 5-1.

Block Errors

Table 5-70 lists conditions reported in the

BLOCK_ERR [6] parameter. Conditions in italics are

not applicable for the DO block and are provided only

for your reference.

Action on Fault Detection

Fault State is caused by one of three sources: A

status pertaining to CAS, A status pertaining to RCAS,

or SET_FSTATE [29] in the resource block. To

implement Fault State, configure the following

parameters:

IO_OPTS [14]: Determines the action OUT_D [9] will

take upon a fault state. If the IO_OPTS [14] “Fault

State to Value” is not selected, then OUT_D [9] holds

its last position when Fault State is set. If “Fault State

to Value” is selected, OUT_D [9] goes to the

FSTATE_VAL_D [20] value when Fault State is set.

FSTATE_TIME [19]: The length of time, in seconds,

that the DO block will wait to set Fault State. When

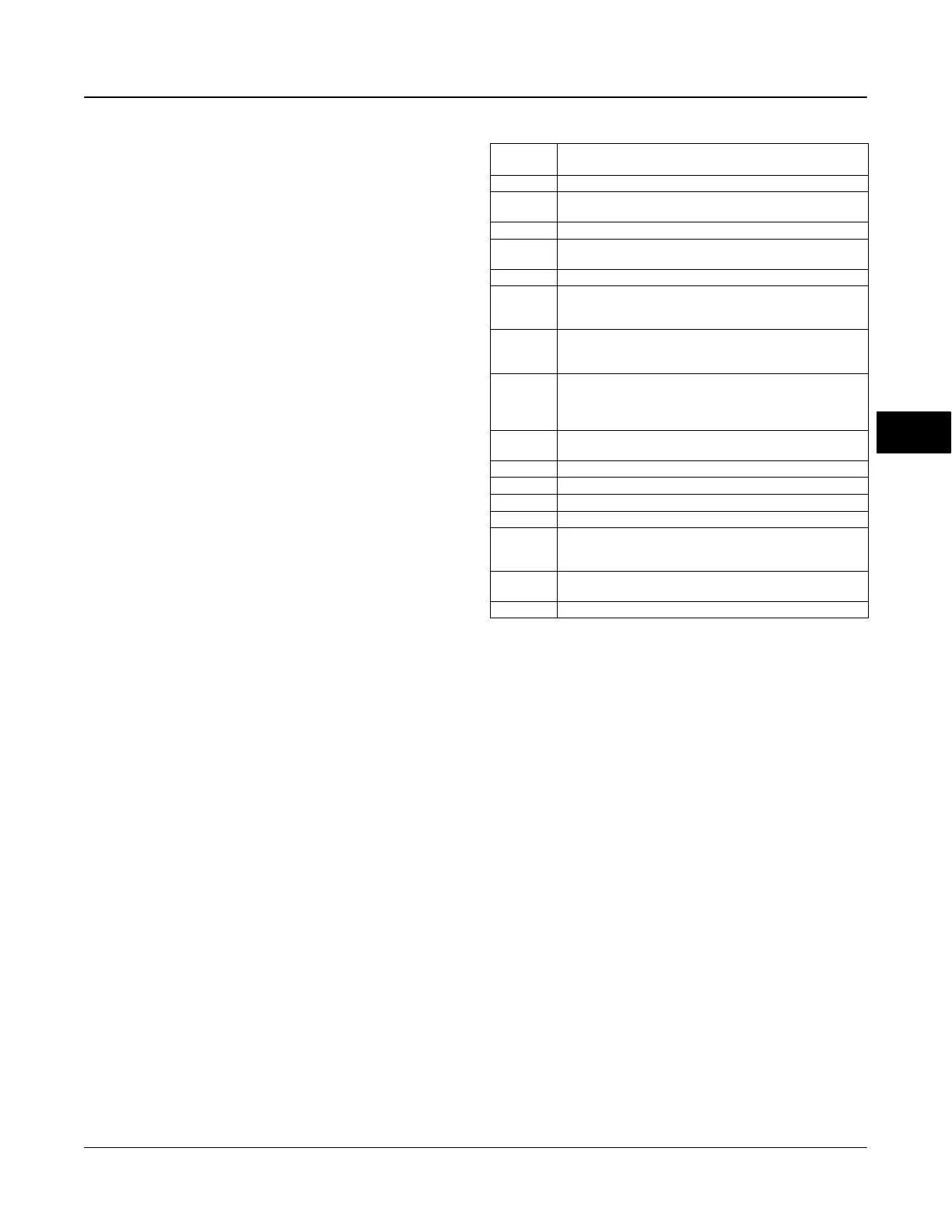

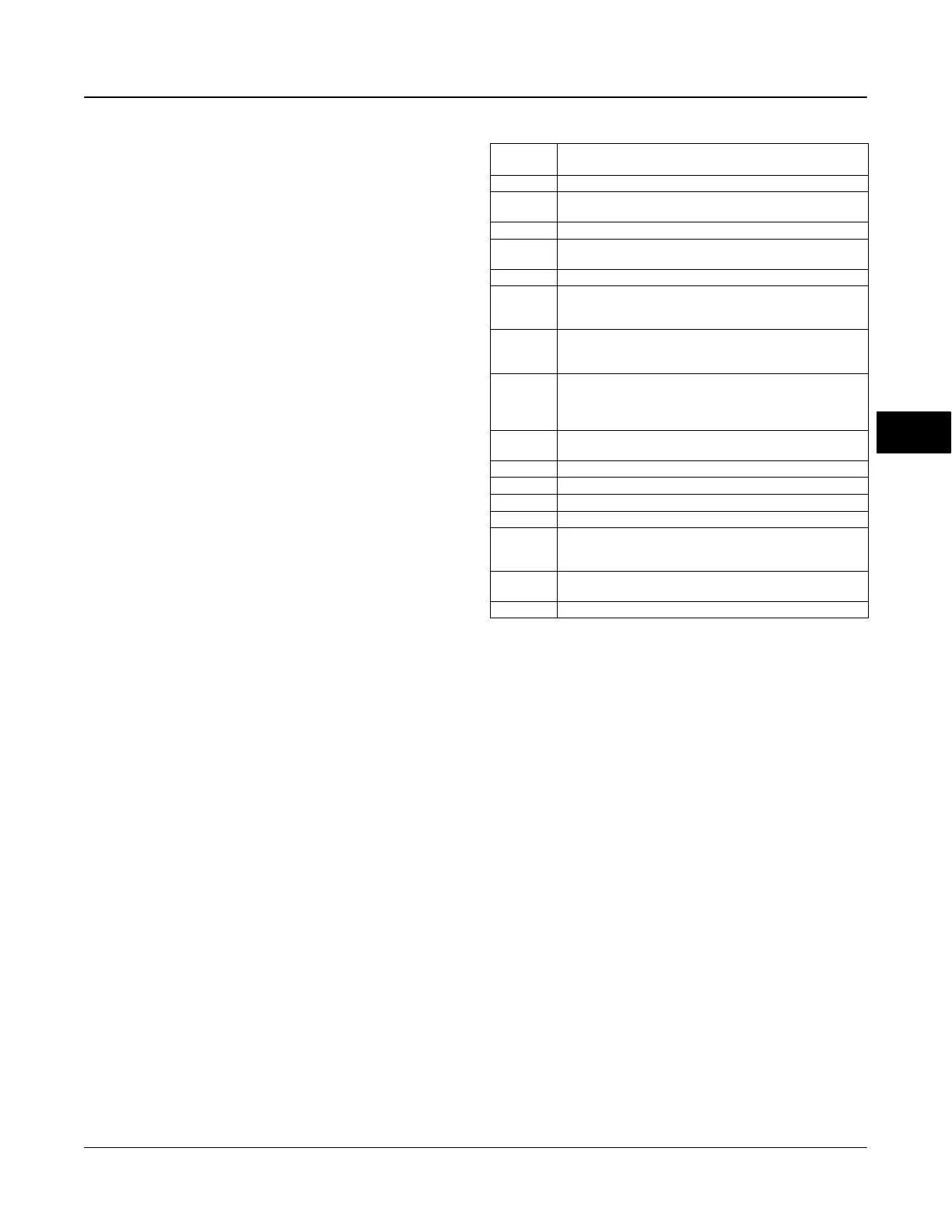

Table 5-70. BLOCK_ERR Conditions

Condition

Number

Condition Name and Description

0 Other (N/A)

1

Block Configuration Error - SHED_OPT or CHANNEL set to

0 (uninitialized)

2 Link Configuration Error (N/A)

3

Simulate active - Simulation is enabled and the block is using

a simulated value in its execution.

4 Local Override - Device in fault state. Actual mode LO.

5

Device Fault State Set - DO block in fault state after

FSTATE_TIME because of Bad status or IFS substatus on

CAS_IN_D or Resource block commanded fault state.

6

Device Needs Maintenance Soon - Indicates a Maintenance

PlantWeb Alert condition is active if Block Error Reporting is

enabled. See page 5-39.

7

Input failure/process variable has Bad status - PV has bad

status and Feature Select in the Resource block has the Out

Readback bit set or the transducer block mode is Out of

Service.

8

Output failure - PV has bad status or the transducer block

mode is Out of Service.

9 Memory Failure (N/A)

10 Lost Static Data (N/A)

11 Lost NV Data (N/A)

12 Readback Check Failed (N/A)

13

Device Needs Maintenance Now - Indicates Failed

PlantWeb Alert condition is active if Block Error Reporting is

enabled. See page 5-39.

14

Power Up - This condition exists after power up until actual

mode is not Out of Service.

15 Out of Service - The block is in Out of Service (OOS) mode.

Fault State is set, the OUT_D [9] value goes to either

the FSTATE_VAL_D [20] value or holds its last

position, depending on I/O_OPTS [14]. When the

block has a target mode of CAS, a fault condition will

be detected if the CAS_IN_D [17] has a BAD status or

an Initiate Fault State substatus is received from the

upstream block.

FSTATE_VAL_D [20]: Determines the OUT_D [9]

value if IO_OPTS [14] “Fault State to Value” is

selected. The OUT_D [9] value transitions to

FSTATE_VAL_D [20] after FSTATE_TIME [19]

elapses and the fault condition has not cleared.

Simulation

To support testing of the control strategy, you can

enable the SIMULATE_D [17] parameter. Normally,

the valve position value and status used for

READBACK_D [16] in the DO block reflect actual

process values to the nearest 5%, as provided by the

transducer block. When the SIMULATE_D [17]

parameter is enabled, value and status used for

READBACK_D [16] is supplied by the user manually.

To enable simulation in the DO function block, the

simulate jumper must be installed. For information on

the installation of this jumper, see the page 2-25

Installation section.

5

Loading...

Loading...