DVC6000f Series

March 2006

9-6

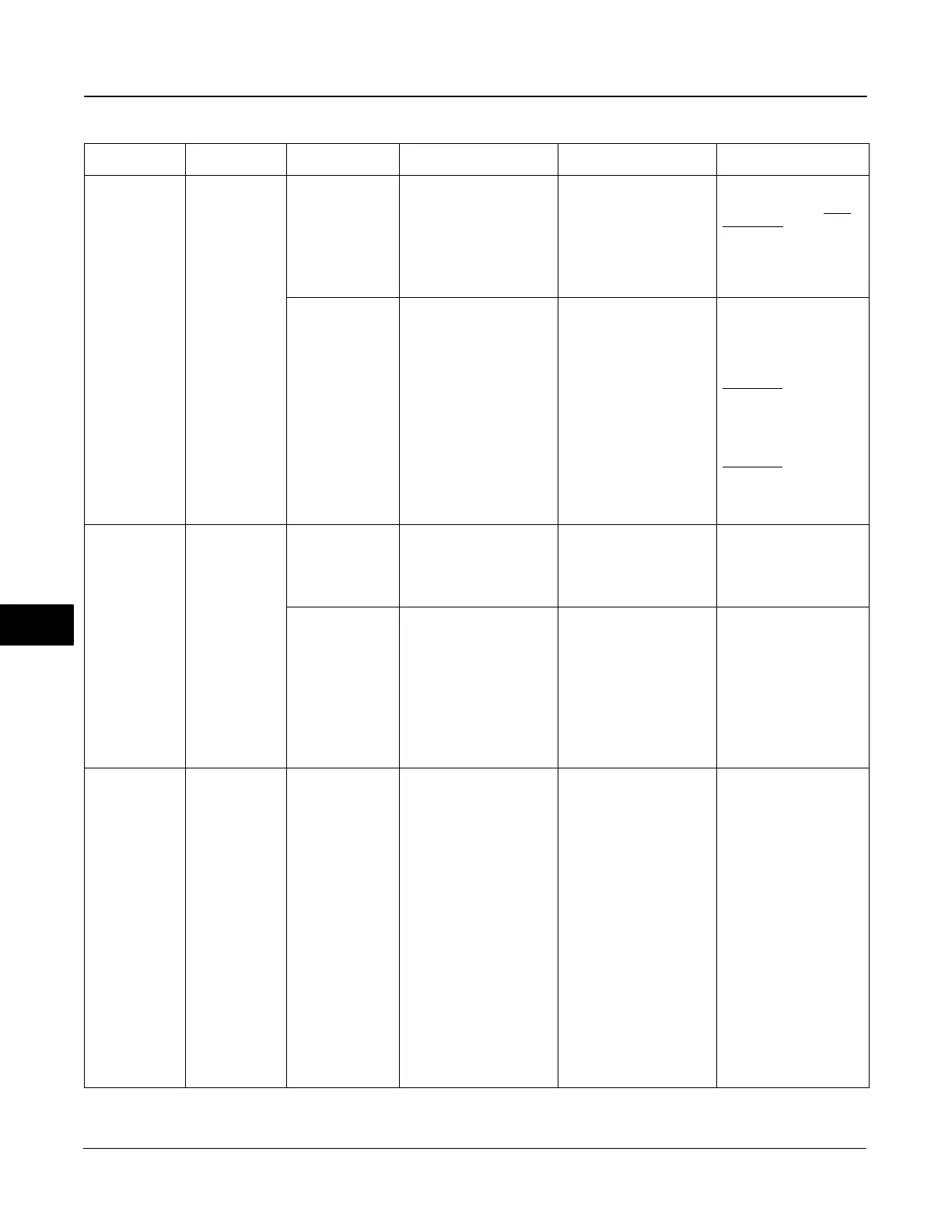

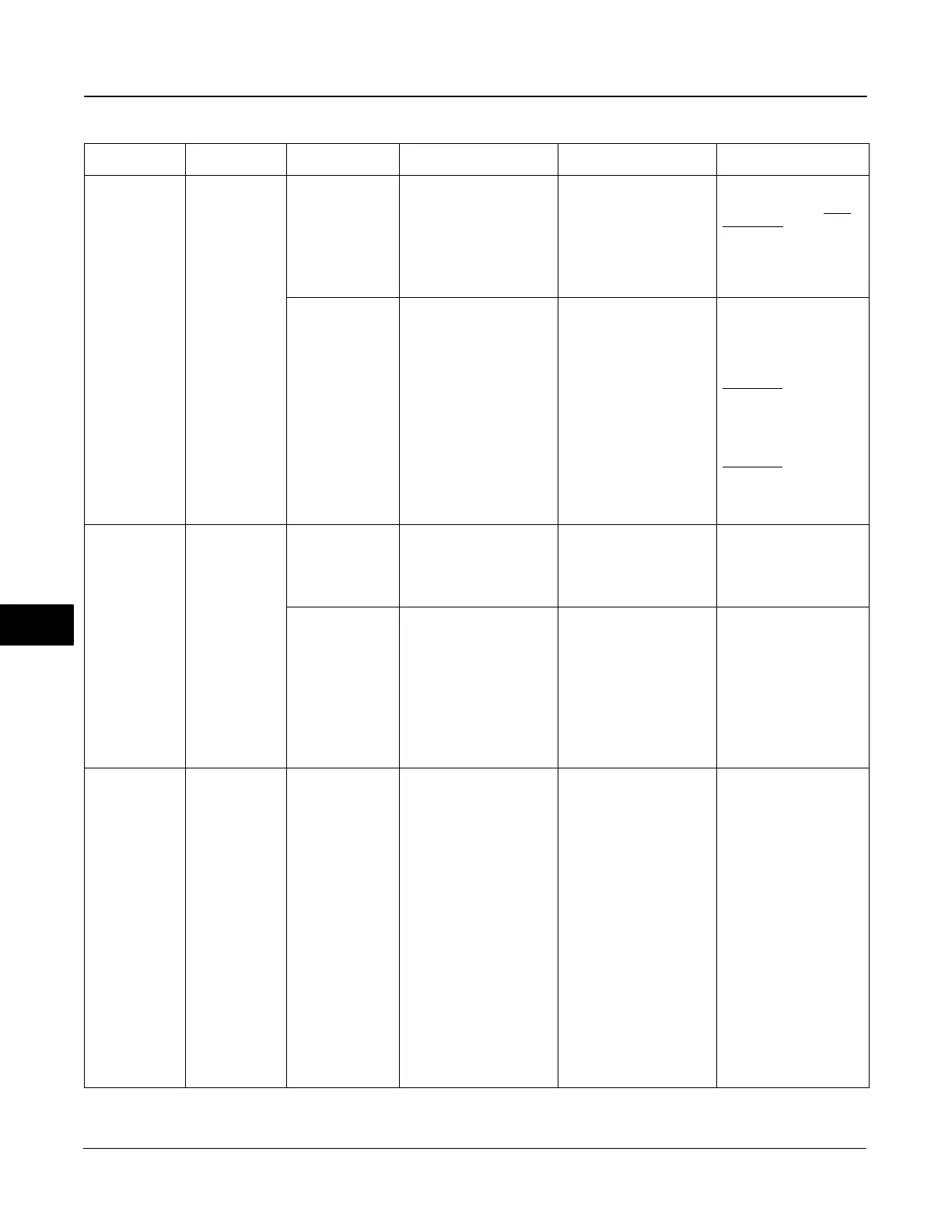

Table 9-1. Setting PlantWeb Alerts (Continued)

PlantWeb Alert

and (Group)

Alert Category

and (Default)

Alert Condition

and (Default)

What the Alert is

Detecting

Related Parameters and

(Default)

Guidelines for Setting

Supply Pressure

(Environment)

User Config.

(Maintenance)

Supply Press High

(Enabled)

The supply pressure reading

is above the user adjusted

threshold.

Alert Point (145 psig)

Enable the alert in the

Maintenance Alert Category.

Set the Alert Point to which

ever is lower of

a. the maximum

instrument pressure of 145

psig or

b. the maximum actuator

casing pressure.

Supply Press Low

(Enabled)

The supply pressure reading

is below the user adjusted

threshold

Alert Point (19 psig)

Enable the alert in the

Maintenance Alert Category.

Double Acting Actuators—

Set the Alert Point above the

minimum required for valve

shutoff and no greater than

1 psig below

the supply

regulator setting

Single Acting Actuators—

Set the Alert Point above the

minimum required for valve

shutoff and no greater than

1 psig below

the supply

regulator setting. This is

generally about 3 psig above

the actuator upper bench set

(stroking) pressure.

Temperature Limit

(Environment)

User Config.

(Advisory)

Temperature High

(Enabled)

The instrument temperature is

above the used adjusted

threshold.

Alert Point ( 186C)

Use default settings

Other alert points may be

chosen to indicate changes

in the instrument

environment.

Temperature Low

(Enabled)

The instrument temperature is

below the user adjusted

threshold.

Alert Point ( −63C)

Enable the alert in the

Maintenance Alert Category.

Set the Alert Point at −40F

if the instrument uses Nitrile

elastomers and −63F if it

uses Fluorosilicone

elastomers.

Other alert points may be

chosen to indicate changes

in the instrument

environment.

Travel Deviation

(Travel)

User Config.

(Maintenance)

Travel Deviation

(Enabled)

The difference between

Setpoint and Travel is greater

than the configured limits.

Alert Point (5%)

Alert Time (10 sec)

Deadband (2%)

Enable the alert in the

Maintenance Alert Category.

Use the default settings with

valves that are 4 inch and

smaller with PTFE packing

systems.

With other valves, the user

can refine the settings with

AMS ValveLink Software

Dynamic Error Band and

Step Response Tests. Set

the related parameters as

follows:

Tvl Dev Alert Point—set

equal times 2 the Maximum

Dynamic Error, minimum 3%

Tvl Dev DB—set equal to

the Dynamic Error Band,

minimum 2%

Tvl Dev Time—set equal to

the T98 time for a Step Test

from 0 to 100% Travel,

minimum 10 seconds.

−Continued−

9

Loading...

Loading...