DVC6000f Series

March 2006

10-18

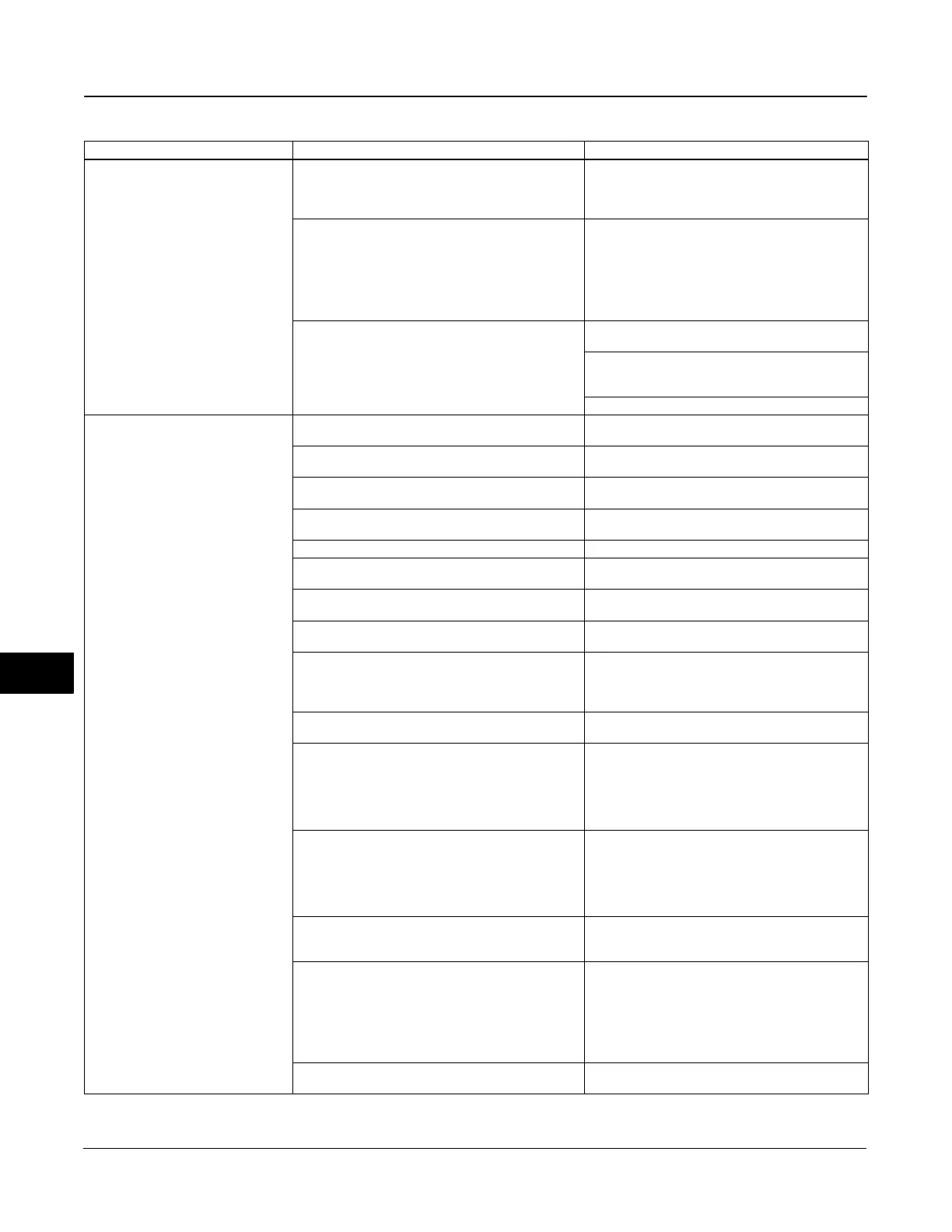

Table 10-2. Instrument Troubleshooting (Continued)

Symptom ActionPossible Cause

13. Valve responds too slowly.

13.e Defective gasket. 13.e Check gasket for closed holes, excessive

deformation due to overtightening or “oozing”. If

necessary, replace gasket (see the beginning of this

section).

13.f Defective relay. 13.f Remove relay, inspect for missing Belleville

washer, missing valve spring, missing valve plug.

Inspect “lip” under top O-ring for breakage due to

relay removal. Inspect O-rings and replace if hard or

damaged. Replace parts or relay if I/P ass’y good

and air passages not blocked (see Replacing the

Pneumatic Relay on page 10-8).

13.g If responds slowly only upon air demand, there

may be a restriction in the air line, the supply run may

be excessively long, or the supply regulator may be

defective or capacity not large enough.

13.g1 Check supply line to ensure it is not clogged or

damaged. Replace if necessary.

13.g2 If supply run is excessively long, a volume tank

may need to be installed on the the supply side of the

pressure regulator

13.g3 Replace supply regulator

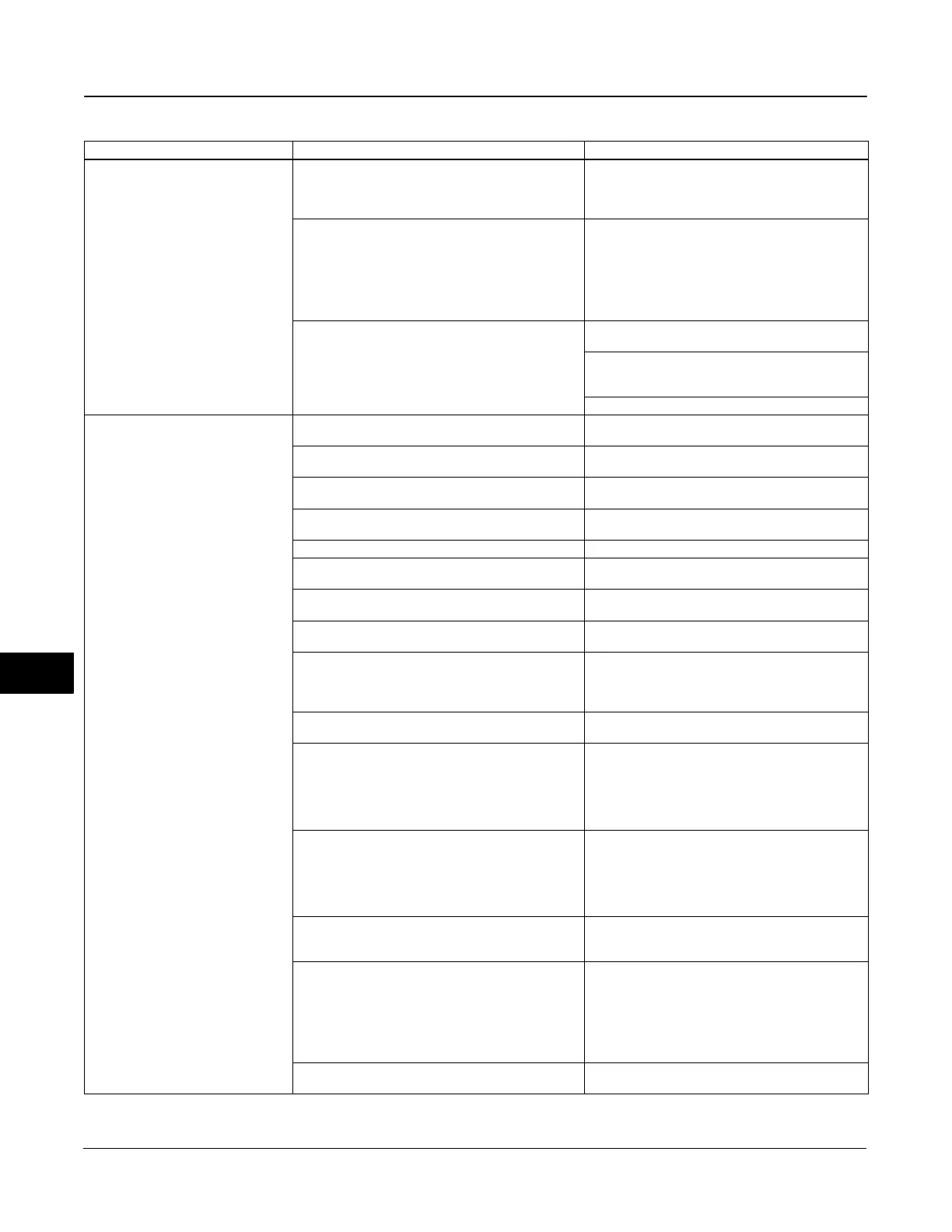

14. Instrument will not calibrate, has

sluggish performance or oscillates.

14.a Travel sensor seized, will not turn. 14.a Rotate feedback arm to ensure it moves freely. If

not, replace the pot/bushing ass’y.

14.b Broken travel sensor wire(s). 14.b Inspect wires for broken solder joint at pot or

broken wire. Replace pot/bushing ass’y.

14.c Travel sensor misadjusted. 14.c Perform Travel Sensor Adjust procedure on

page 6-7 of the Calibration section.

14.d Open travel sensor. 14.d Check for continuity in electrical travel range. If

necessary, replace pot/bushing ass’y.

14.e Cables not plugged into PWB correctly. 14.e Inspect connections and correct.

14.f Feedback arm loose on pot. 14.f Perform Travel Sensor Adjust procedure on page

6-7 of the Calibration section.

14.g Feedback arm bent/damaged or bias spring

missing/damaged.

14.g Replace feedback arm and bias spring.

14.h Configuration errors. 14.h Verify configuration. See Initial Setup on

page 5-23 or use Setup Wizard on page 4-2.

14.j Restricted pneumatic passages in I/P converter 14.j Check screen in I/P converter supply port of the

module base. Replace if necessary. If passages in I/P

converter restricted, replace I/P converter (see

Replacing the I/P Converter on page 10-6).

14.k O-ring(s) between I/P converter ass’y missing or

hard and flattened losing seal.

14.k Replace O-ring(s) (refer to the I/P Converter

section on page 10-6).

14.l I/P converter ass’y damaged/corroded/clogged. 14.l Check for bent flapper, open coil (continuity),

contamination, staining, or dirty air supply. Coil

resistance should be between 1680 - 1860 ohms.

Replace I/P ass’y if damaged, corroded, clogged, or

open coil (see Replacing the I/P Converter on page

10-6).

14.m I/P converter ass’y out of spec. 14.m I/P converter ass’y nozzle may have been

adjusted. Verify drive signal (55 to 80% for

double-acting; 60 to 85% for single-acting) with the

valve off the stops. Replace I/P converter ass’y if

drive signal is continuously high or low (see Replacing

the I/P Converter on page 10-6).

14.n Defective module base seal. 14.n Check module base seal for condition and

position. If necessary, replace seal. Refer to Module

Base Maintenance on page 10-3.

14.p Defective relay. 14.p Depress relay beam at adjustment location in

shroud, look for increase in output pressure. Remove

relay, inspect relay seal. Replace relay seal or relay if

I/P converter ass’y good and air passages not blocked

(refer to Replacing the Pneumatic Relay on page

10-8). Check relay adjustment (refer to page 6-5 of

the Calibration Section).

14.q Defective 67CFR regulator, supply pressure gauge

jumps around.

14.q Replace 67CFR regulator.

−Continued−

10

Loading...

Loading...